Clay plaster: composition and features of use

Clay plaster on the one hand is a wonderful material in its functionality, but on the other hand it is not so easy to prepare. Although for a certain list of works it is simply not replaceable.

Today you will learn how clay plaster is made, also get acquainted with its properties nuances of preparation. The video in this article will help you decide how much it will suit in your case.

The content of the article

Choose the clay composition and make

The price of the solution is not high, but not everyone can cook it. Here you need to have patience. There is a different clay content and this causes certain difficulties. Choosing a composition for heating structures is not a simple matter.

Here you need to think through everything:

- On the one hand, the material must be durable, aesthetically attractive and not harm the health. On the other - fit into the planned budget, which is often limited in times of crisis.

- Clay plaster composition that meets all the stated requirements. It has been used in construction technology for a long time and during this time has not lost its relevance.

Attention: Of course, the material is not simple, and requires certain skills, but if everything is done correctly, the result will please you for more than one year.

The main properties of clay plaster

Nowadays, air polluted by enterprises and cars contains almost the entire periodic table. Adding to this chemistry, which is part of construction and decoration materials, it will turn out what you and your children breathe every day.

In such a situation, the decision to buy a product that is not harmful to health and improves the microclimate of your home is especially important. But environmental cleanliness is not the only plus.

Let's look at other advantages of clay plaster:

- Filtering properties. Do not let harmful substances from outside into your home.

- Chemical freetherefore safe for allergy sufferers.

- Hygroscopicity - the ability to absorb and retain moisture. It maintains humidity in the room at the level of 40-60%, and this is the best indicator for a comfortable life.

- Strength and durability. A properly prepared composition will last for many years.

- Easy care and restoration. When chips or cracks appear, there is no need to redo the entire volume, it is enough to apply the solution to the damaged area and allow to dry.

- Refractoriness and waterproofing. Clay does not burn and reliably protects walls from the harmful effects of moisture.

- It does not harm nature. No problems with waste disposal.

- Suitable for all surfaces.. It fits well on the walls of any material, whether it is wood, stone, concrete or brick.

With all its advantages, this type of coating will cost quite inexpensively. Before ordering a product, you can compare its price with the cost of similar products. Clay plaster is several times cheaper.

Possible difficulties in work

Clay is a whimsical material and in the hands of an inexperienced master can cause some difficulties:

Attention: The problem is that there is no exact formulation for the preparation of the solution. The proportions depend on the natural elasticity (“fat content”) of the source material, and it may vary depending on the place of production. The readiness of the solution is determined empirically. In case of an error, the surface will be brittle and crack.

- Clay plaster dries for a long time.It will take several months to dry the coating in two layers. It is important that drying takes place in vivo. Using an industrial hair dryer or heater will cause cracks and a decrease in strength.

- When using clay plaster for exterior decoration of a house (see Exterior wall plastering: traditional facade finish), the coating is best treated with a water-repellent solution or special paint. Otherwise, under the influence of snow, rain and the sun, cracks will begin to appear on the surface, and you will have to redecorate the facade almost every year.

- In addition, clay is an excellent absorbent and well absorbs harmful substances from the environment. Therefore, before buying a product, make sure that there is no chemical or other harmful production near the quarry.

How to prepare a solution

Stucco walls with clay do-it-yourself begins with the preparation of the desired composition. Here the environment and the expected temperature regime will play a role.

The classic composition of clay plaster includes:

- Sand (plasticity of the solution);

- Filler (coating strength);

- Water;

- Clay.

To give the coating special properties, special additives are used:

- For walls affected by mold, fungus, or surfaces with traces of soot, copper sulfate (20-100 g per 4 buckets of clay) is added to the plaster.

- For processing stoves and fireplaces, a composition with asbestos is used (proportion 1:10).

- To reduce the drying time, gypsum is used.

- For disinfection and bleaching - lime.

Attention: if you use solid fuel, then the plaster of the stove is made with chamotte clay. It tolerates fairly high temperatures. You just need to add 15% fireclay to the composition.

- Clay can be extracted independently. But the pit will have to dig a large one - a suitable breed lies at a depth of 1-1.5 m, and a lot of it will be required. Therefore, it is easier to order a product that is already completely ready for use.

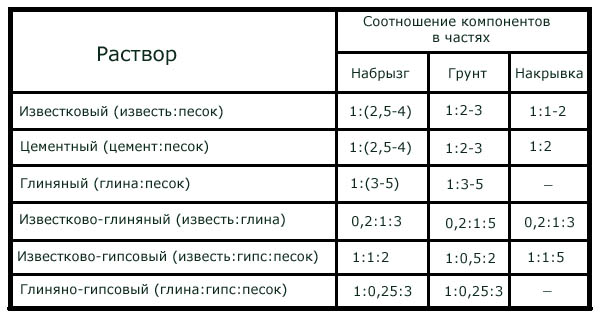

- Before preparing the plaster for the rough coat, sand and aggregate must be sieved. The ratio of clay and sand from 1: 2 to 1: 5, depending on the "fat" of the clay. As a filler, hay, chopped straw, sawdust (previously soaked), wool or even propylene fiber are used.

Caution: Mix pre-soaked (1-2 days) and mashed clay with filler and additives. Sand and water are introduced into the solution gradually, with constant stirring. The mixture should be uniform and not stick to your hands. The readiness of the composition is determined empirically.

- Sliding from a clean wet trowel, the mixture should leave marks (tracks). Too dirty, or a clean trowel - respectively a "greasy" or "skinny" solution.

- Bend the sausage 1.5-2.0 cm thick and 20-25 cm long into an arc. The stronger the bend, the more plastic the solution.

- A flattened bun (2-3 cm in diameter) should not crack around the edges.

- The final layer (grout) is prepared from clay, sand and water. Filler is not needed at this stage. The composition will be more durable if we add building cement to it (the ratio of cement M400 and clay is 1: 5).

Caution: This mixture is used immediately (for a maximum of two hours). If you apply an old (especially re-soaked) solution - the coating will be weak and will quickly crack.

How to apply clay plaster - step by step instructions

Now we will consider how to plaster clay walls. In work, there is a certain consistently there is also its own rules.

The work is carried out in two stages (draft and finishing coat) in the following cases:

- During the initial processing of walls after construction;

- For warming and soundproofing the room;

- For leveling surfaces with strong slopes and bumps.

Attention: For finishing a relatively flat wall, one finishing layer with a thickness of 1-2 cm will be enough.

- Stucco Furnace clay is first determined by the thickness of the layer. Here you need to pull the fishing line along the diagonals and you will immediately see the deviations;

- Plastering clay walls with a thickness of more than 2 cm is done only with reinforcement. To do this, a building grid is placed on the wall. Also make sure that it is evenly distributed over the entire plane.

The main stages of the work:

| Wall preparation | Fill the wooden grate (shingles) on the base of wood, on the wall of brick or blocks - open the seams. The more roughness, the better the adhesion of clay to the surface. Before starting work, the wall must be cleaned of dust and moistened with water. |

| Solution application | Clay plaster does not deteriorate over time (except for compositions with cement), which is very convenient for an inexperienced master.

|

| Drying | Drying will take 1 to 2 months (depending on temperature and layer thickness). Drying should take place under natural conditions without the use of heating elements. |

| Application of a finishing layer | To do this, use a more liquid composition. The thickness of the finishing layer is 1-2 cm, so it will dry in 1-2 weeks. |

- If clay stucco remains (even in diluted form, but without cement in the composition), it will not deteriorate over time. It can also be used after many years for repair, restoration of walls or as a putty for drywall.

- Clay-plastered walls can be left in kind or whitewashed. If the plaster is sanded, treated with a deeply penetrating primer and gypsum putty, the walls can be painted or glued with wallpaper. You can use decorative trim or stucco. Using clay plaster, you can create almost any interior using environmentally friendly material, and without extra costs.

How to plaster clay walls of the video will help to do the job quickly and efficiently and not to miss anything. You have instructions and you can make a quality composition, and looking at the photo you will see all the work in the right sequence.