Clay stucco: where to use

Today, when we, saturated with modern technologies, again strive to decorate our homes with environmentally friendly materials that do not contain toxic and unhealthy substances, clay plaster is becoming more popular again - its composition is completely natural, nature gave us all the components.

Unfortunately, the good masters who know perfectly the technology of its preparation and application are becoming less and less, but if you wish, you can deal with this matter yourself.

The content of the article

Than clay plaster is good

Almost all packages with modern stucco mixes (see Types of plasters for interior decoration: choose correctly) there is a note on the environmental safety of the product. And in most cases it is true. And yet, they often include synthetic additives that give the material plasticity, frost resistance, increased strength and other useful properties.

Clay plasters completely consist only of natural materials: clay itself, sand and such fillers as sawdust, straw, needles, etc. They have a lot of advantages that even the most high-quality and expensive plasters on cement, gypsum do not have (see. Cement or gypsum plaster: which is better to choose) and, moreover, a polymer basis.

So:

- With its excellent ability to accumulate moisture from the air and give it back, the clay carries out climate control in the room;

- It also accumulates heat and gradually gives it away as the air temperature drops. Even to the touch, it is always warm and pleasant;

- Such plaster absorbs odors perfectly, is a good barrier to extraneous sounds from the street and high-frequency radiation;

- It has antiseptic properties, prevents the appearance of mold on the walls;

- Another great feature is the ability to “breathe” by letting the airborne vapors pass through. Wooden structures with such protection always remain dry, do not rot and are not attacked by pests;

- Clay plaster can be reused by soaking it with water. They also come with a frozen working solution, so no waste remains during the repair;

- It can be used on any basis: wooden, brick, concrete, cinder block, etc .;

- Of course, the extremely low price of the material is also an important plus. It may cost you nothing at all if clay is used for plastering from a foundation pit dug under the foundation, and sand is brought from the river bank. But ready-made mixtures are usually no more expensive gypsum plasters.

Tip. When buying such a plaster, pay attention to where the clay was extracted. It adsorbs well not only odors, but also various harmful contaminants, including radioactive ones.

Preparation of plaster

Unfortunately, it is quite difficult to prepare the mortar and plaster the walls with it yourself.

This process is not only labor-intensive, but also very long: the clay dries for a long time. But the result is worth it, so for those who decided to use this material, we offer to see how the stucco clay video is performed and carefully study the recommendations below.

What should be included in the plaster

The main components are ordinary clay, sand and water. A solution prepared only from them has a high thermal conductivity, therefore, it is usually used only to make the final leveling layer. For rough finishing, the task of which is to strengthen the thermal insulation of the walls, they make stucco with filler.

It can be:

- Chopping straw or hay;

- Hemp or flax fiber;

- Wood sawdust or shavings, preferably pine, oak, alder;

- Kizyak (horse manure).

All these materials have long been used by our ancestors, and they knew a lot about the insulation of their homes. Today, modern fillers have been added to them, which can be used without fear. These include various fibers and granular polystyrene foam.

There are other options:

- For example, if you plan to plaster stoves with clay, then cement, asbestos or fiberglass is often added to the mortar to give the plaster more strength.

- For the manufacture of decorative clay plaster, colored clay (white, yellow, blue) is used, pigments and ground mineral fillers are added to it.

Solution preparation

You can use any clay, but it can be of different fat content, so you will have to experimentally determine the ratio of all components in the plaster. To adjust the proportions, first prepare a little solution.

The instruction is as follows:

- Take one part of the clay and fill it with water for a day, which should be 3-4 times more in volume;

- Mix the solution thoroughly, kneading all the lumps until a homogeneous mass is obtained;

- Stirring periodically, start adding sifted sand to it. For clay of normal fat content, four parts of sand are required, but pour it until the mass begins to slide off the trowel easily.

Now you need to test one of the following ways:

- Method 1 Roll up a small ball, lift it a meter from the floor and drop it. It should not fall apart or crack from impact.

- Method 2 Roll out a bundle of 15-20 cm long and about 2 cm in diameter from the resulting mass, lay it on a flat surface and bend it with an arc. Tears and cracks should not appear on the bend.

If your samples do not pass the test, it means that they have too much sand.

Having ascertained the proportions, it is possible to prepare the solution in the right volume by adding fillers and water to it. Sawdust or chopped straw for heat-insulating rough plaster should be about half of the total volume or slightly less. Add them gradually and water until you get a kneading of the desired consistency.

Tip. Do not use dry sawdust, otherwise they will absorb water from the solution. Soak them in advance.

Now it's time to learn how to plaster with clay.

Stucco walls with clay mortar

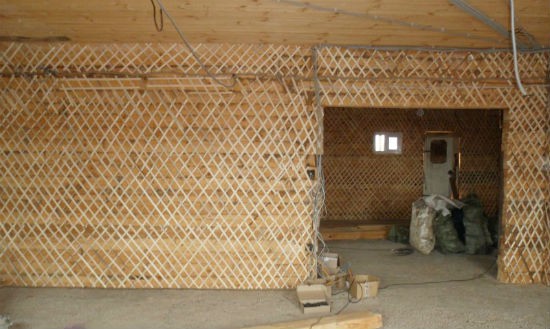

Apply the clay clay on the shingles. Rather, it has the first working layer, the thickness of which must be at least 3 cm, so that the clay "works" for heat saving and maintaining a normal microclimate in the room.

A shingle is a wooden battens made of wood. It will serve as reinforcement for a rather heavy coating.

A solution for better adhesion to the surface literally pounces on it with the use of force, and then with pressure is leveled by the rule in the direction from the bottom up, to the sides, but not top to bottom.

Tip. Before plastering clay, moisten the walls well.

After 10-15 minutes, the surface is smoothed with a wooden grater, which must be periodically moistened in water. Especially if the coating has already begun to dry.

This layer should dry well before applying the topcoat. Depending on the air temperature and the thickness of the plaster, this can take from one to three months.

The solution for the leveling layer is prepared without filler, for strength, cement or gypsum can be added to it in a ratio of 1: 1 with respect to clay. It is applied in a thin layer 2-5 mm thick in the same way as regular plaster.

Conclusion

Very often we have to choose between the price and quality of the material, ease of application and environmental safety. Clay plaster has many advantages, but working with it is difficult, especially not having experience in this matter.

The video in this article will help you better understand the whole process, but you still can’t get away from the physical component. Therefore, calculate your strength and be sure to find an assistant for this work.