How to plaster a brick stove with your own hands

Gas or central heating has come to almost every home today, but despite this, wood stoves do not lose their popularity. This is due to many factors, here is the environmental friendliness of the fuel, and in some way saving, especially when it comes to bringing gas wiring to a section remote from the highway.

But, despite all the popularity, many still wonder how to plaster a brick stove so that the coating does not begin to crumble after a few years. In fact, there is nothing complicated here, and in this article we will try to prove this statement.

The content of the article

Furnace preparation

Talking that plastering a brick oven is a complex process that only professionals can do is nothing more than a bike. In fact, this can be done with one's own hands, even if there was no such experience before.

So:

- Like any repair or finishing work, the plaster should begin with the preparation of the furnace and its surface. This is especially important if the stove is recently folded and this is its first finish. In this case, thorough drying is necessary. In vivo, it can last several months, so you can speed up the process and lightly melt the furnace.

- This should be done only a few hours a day, and after a week the surface will be completely ready for use.

Important! In addition to drying the masonry, the stove must go through the natural shrinkage stage, otherwise the plaster may begin to crack regardless of the quality of the work done.

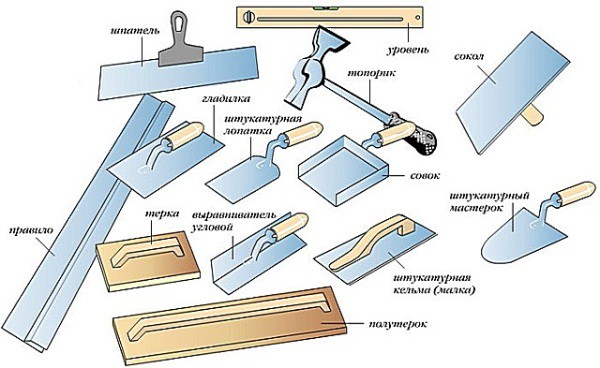

- In order for the coating to turn out smooth and without differences, before plastering the stove from a brick, you need to fix the beacons on it, as shown in the photo at the beginning of this article. They serve to ensure that the tool with which the mixture is applied does not push the surface more than necessary.

- The lighthouses themselves are made of metal, so they are not afraid of even a very high temperature. But more on that later.

Preparing a solution

So:

- Progress, which does not stand still, has reached the stoves, today you can buy a ready-made mixture, to which detailed instructions for applying it are attached. But proponents of classical plaster try to prepare the solution on their own. Whether this makes sense is not known, since the price will differ slightly, but we will nevertheless describe several options.

Advice! Before buying a finished mixture, you should definitely know its composition and the maximum temperature that it can withstand.

- Just a few, because there is a difference between how to plaster a brick pipe and how to plaster the stove itself. It consists in the temperature difference between the "body" and the chimney, and in addition there are special mixtures for plastering pipes that are outdoors. But first things first.

Plaster mixes

| Solution composition | Brick kiln parts | ||

| Outer pipe | Inner pipe | Bake | |

| Cement M500 | 1 | 1 | – |

| Red clay | – | – | 1 |

| Slaked lime | 1 | – | – |

| Fine sand | 2-4 | 5 | 1 |

| Additional additives | Preferably | optional | Not desirable |

So:

- It is customary to use asbestos in the form of small fibers as additional additives, it does not burn and maintains the temperature well, but in recent years more and more debate has flared up around this material. Some say that it is extremely harmful to health, while others deny it.

- In any case, we will not advise adding it to the mortar mixture for the plastering of brick stoves, and we will leave this question to everyone's discretion.

- To prepare the solution, it is enough to mix all the ingredients in one container and dilute them with water to the desired consistency. Most importantly, do not forget that the lime must be slaked, but how to make it correctly is shown in the video in this article.

Plastering oven

Choosing how to plaster a brick oven, you can go directly to work.

It occurs in several stages:

- We heat the oven and allow it to cool to room temperature, but do not allow it to cool until the masonry begins to absorb new moisture.

- We thoroughly clean the dried surface with a brush or a broom. The main thing is to remove all the dust and not let it lie back down again.

- We dilute the clay in a separate bucket to a liquid state and apply the mixture to the surface with a thick brush. This will wet the oven under the primary layer and create additional adhesion to the plaster.

- Now fasten the lighthouses. This can be done on the same mortar, which reliably fixes them on the surface.

- The next stage is the fastening of the reinforcing mesh. It can be made of metal or heat-resistant fiberglass, the main thing is that the mesh size should not exceed 2 cm. Previously, burlap was used as reinforcement, which was glued to the furnace and covered with plaster, but this protection has more minuses than pluses, which means there is no point in sacrificing quality for the sake of tradition.

- Next, apply the first layer of plaster, which should cover the reinforcing mesh, but not reach the level of lighthouses. Now he needs to be allowed to dry well, but without melting the stove.

- When the first layer has dried up, we apply the finish coating, focusing on the beacons. Two layers reliably adhere to each other, and after another drying, the surface can be sanded with fine sandpaper.

- When the plaster coating is leveled, the oven can be painted.

Conclusion

We hope that we managed to debunk the myth about the complexity of the plastering of the stove. As you can see, this process, although time-consuming, but completely uncomplicated.

By the way, often the stoves are not plastered at all, and the brick itself, with even and neat masonry, acts as a decorative finish. Also a lot depends on the location. But wherever a brick oven stands, the plastered version not only looks better, but also holds heat much better.