Stucco for cellular concrete: how to choose

The low weight of cellular concrete products, high thermal insulation properties, and, of course, a fairly low price - all this made it possible to use products from it in low-rise housing construction. But there are many nuances and "undercurrents".

To work with porous blocks, you need to know a lot: how to properly masonry, what plaster is used for cellular concrete, by what technology it is applied. It’s even important how this or that type of screed interacts with the finish.

With the help of the video in this article, we will try to give you the most complete information regarding the wet finish of such surfaces - both with internal and external application of plaster.

The content of the article

Brief information about cellular concrete

When planning a house construction from aerated concrete blocks, you must, at a minimum, be aware of the characteristics and characteristics of the material with which you are dealing. Indeed, the advertisement from which many people draw information is the “engine” for trade, and not for construction.

It is clear that cellular blocks are light and inexpensive, and houses built from them are warm and quite durable. But for this to be the case, you need to try not to make mistakes. And it doesn’t matter whether you do the work yourself or hired a team - experts in fact sometimes turn out to be so-so.

Porous blocks: what is the difference

The cellular concrete received its definition because of the structure with evenly distributed small pores, which is very clearly visible in the photo below. Cells in the thickness of this building material are equally an advantage and a disadvantage that must be taken into account in the work.

- This is a separate group belonging to the category of lightweight concrete. The solutions included in it are made of finely divided silica fillers, astringent, pore-forming additives. This group includes several types of concrete, differing in composition and manufacturing technology. They are classified according to different indicators, and first of all, according to the conditions of solidification.

Note! The first group is autoclaved concrete, for which, at high temperature and a certain pressure, they create an atmosphere in the form of saturated steam. It is in this category that everyone knows: gas blocks, gas silicate blocks and foam blocks.

- Autoclave-free concrete includes so-called ash-concrete, for which granular materials are used as aggregate: blast furnace slag, expanded clay, agloporite. Such products do not harden in autoclaves, but in steaming chambers, or using electric heating. At the same time, the air pressure is normal, and the temperature is half as low as in an autoclave - only 90, maximum 100 degrees Celsius.

- The second feature by which cellular concrete is classified is pore formation technology. This is either gas evolution, in which the pores are open, or foaming - the pores in such concrete have a closed structure. This affects the degree of absorption of moisture by the product, and should be taken into account when laying and wall cladding.

- Autoclaved concrete is also classified by the type of binder used.There are purely cement options, for example: aerated concrete. If cement is combined with quicklime, ground lime, then it is already gas silicate concrete. There are options where instead of lime, additives from fine blast furnace slag are used.

Important! In the foam concrete, cement may not exist at all - sometimes it is completely replaced by the same lime or slag. Strength indicators depend on the cement content, and for cementless products they are the lowest. Such blocks are intended for the construction of non-load-bearing enclosing structures: interior partitions, balcony parapets - and can simply be used as heat-insulating material.

- Therefore, before plastering cellular concrete, you need to know exactly which version of the blocks was used for masonry walls. It is clear that cementless blocks are cheaper, and this attracts those for whom saving is always in the first place.

- We will not talk about what can happen if we apply them for the construction of load-bearing walls. But even if these are internal partitions, when plastering you need to keep in mind that in this case, cement-based mortars can not be used.

- This is the main axiom that is followed in construction: the strength of the covering layer cannot be higher than the strength of the base. In accordance with it, the masonry of cementless foam blocks cannot be likewise tiled, since the adhesive is always on a cement basis. Autoclaveless concrete is mainly made on the basis of cement, so there are no such problems with them.

- The merits of cellular concrete products have already been said, but we should not forget about the disadvantages. Besides the fact that they practically “drink water”, they exhibit weak crack resistance and significant shrinkage. It can leak up to 240 days, so in such houses even windows are not immediately installed - what can we say about plaster! It is best done at least six months after the construction of the walls.

If there is a need to do it faster, the masonry needs to be heated by electric heating, and certainly not start finishing in the winter. And yet, you need to observe the order of work: first you should completely finish all the wet processes inside, and then just start facade decoration. At the same time, the external finish option does not affect the order of the work.

Plastering aerated concrete walls: technological subtleties

As already mentioned, the porous structure of cellular concrete blocks is not only their advantage. One of their properties is high vapor permeability. On the one hand, this is good, since the wall "breathes" - on the other hand, the constant presence of moisture destroys the material, and this process must be prevented.

During operation, steam forms inside the building, as we use water, prepare food, and breathe. The number one task that needs to be solved when finishing cellular concrete walls is to allow the steam not to condense inside the structures, but to freely go outside.

Our instructions are even more devoted to this issue than to the process of applying plaster, because in this regard there is no difference: to plaster a brick wall or block masonry (see. How to plaster foam blocks according to technology) The main thing, taking into account all the features of porous blocks, is to correctly assemble the materials for wall decoration. What do we mean? You will learn about this in the next chapter.

The principle of selection of finishing materials for porous concrete walls

The fact is that it is up to you to decide what composition to plaster the surfaces inside the house (see Types of plasters for interior decoration: choose correctly), it is necessary in a complex, considering what the finishing will be. In addition, you must immediately decide on the option of facade decoration, as it is of great importance for the selection of interior materials.This is the dilemma, and we will try to explain its significance.

So:

- When it comes to indoor plastering, the cost of buying materials can be reduced, since all types of existing solutions are suitable for such work. The main thing is that the cement plaster does not appear on the surface of the masonry from cementless blocks, but this was already mentioned in the previous chapter.

- This facade plaster for aerated concrete should be resistant to low temperatures, and contain anti-frost additives that provide this property. In residential premises, there is no such problem, so the solution can be almost any, and not necessarily purchased.

- You can use a self-mixing mortar based on cement grade M400, which is mixed with sand in a ratio of 1: 5. If the brand is higher - M500 or M600, then the ratio can be made even 1: 6.

For plastering, gypsum, cement-lime and gypsum-lime mixtures are also excellent, which are much cheaper than assembly adhesive for blocks, which, by the way, can also be used for this purpose. And here it is important not so much than to plaster, how important is the finish option.

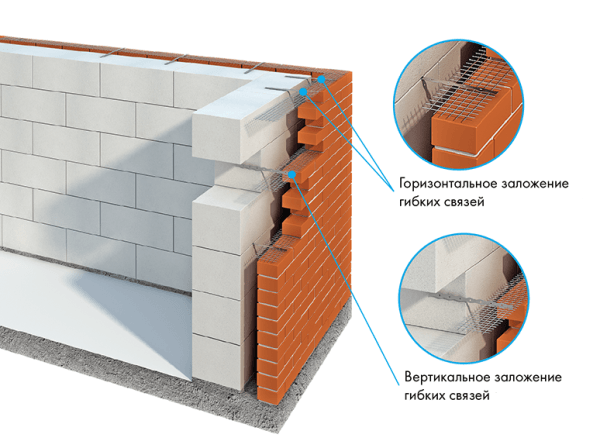

Brick-faced cellular concrete walls

Walls erected from blocks are often faced with brick during the laying process (see Brick home decoration: inside and out) In this case, you don’t have to worry about the exterior decoration, but this has a certain effect on the interior decoration. It is best if there is a ventilation gap between the supporting and decorative wall, which will allow the steam to freely leave the masonry.

- But often the brick is laid close to the blocks, creating not a ventilated, but a monolithic facade. And this is what happens: the vapor permeability of a brick is much lower than that of aerated concrete, and it turns out that the steam, passing through the block, abuts against the barrier.

- In this case, between the two surfaces begins the process of condensation of moisture, and its accumulation. In summer, this may not be so scary, but in winter, water turns into ice. Multiple freezing and thawing cycles can quickly destroy the structure, and this situation is undesirable.

- Even worse, if you put a heater in the form of extruded polystyrene foam into the ventilated space by sticking it on the walls. It is generally practically impervious to vapors and completely traps moisture in the wall.

- If polystyrene foam is to be used, then plates of the lowest density, with a coarse-grained structure should be used - or soft mineral wool should be taken. For the same reason, if we are plastering a facade made of aerated concrete, then it is better to do this on the base surface, and not on the insulation. The reason is that in warm plaster systems a heater of the highest possible density should be used.

- In principle, no matter what material is chosen for finishing the facade, its vapor permeability will still be lower than that of a gas or foam block. Therefore, it is important to protect the flow of steam into the structure from the inside. Gypsum plaster, which is most often used for internal work, is most permeable to steam - especially if it is painted with PVA-based water emulsion or chalky whitewashing is performed.

- That is, the gypsum will freely pass the fumes into the structure, and if it turns out that the output is tightly sealed outside, soon unpleasant consequences will be felt. In the presence of a ventilation gap, any plaster can be used, since from the side of the facade the pairs will easily exit through technological products.

- When there is no way out for steam outside: let's say the walls are tiled - you need to try so that there is no entrance from the inside.To do this, you just need to choose the right finishing materials. If you want to glue the wallpaper, then you need to give preference not to the paper version, but to the non-woven, which is completely impenetrable for water and steam.

- But under the painting of the walls, you need to perform a cement screed. It will not allow steam to enter the structures - it is not in vain that in wet rooms it is recommended to use plasters on a cement rather than gypsum basis.

- Why are gypsum plasters so popular when it comes to interior decoration? The reason for this is its white color, which facilitates the finish. A dark cement screed can shine through even wallpaper, if they are light and thin - what can we say about water-dispersion paint.

There is a simple way out of this situation: the primer applied before color staining can be tinted in the desired shade. For whitewashing or wallpaper, you can purchase a pigmented primer, which mows the treated surface in white.

Of course, no one does the same decoration in all rooms, just when selecting materials you need to follow the principle that was mentioned above.

The nuances of applying plaster

As always, the walls must first be primed. The composition of deep penetration should be used - and, unlike brickwork or panel walls made of heavy concrete, it is necessary to process the surface twice. The easiest way to do this is with a spray gun, or a conventional garden sprayer.

So:

- Before the second coat is applied, the first must dry within the time allotted by the manufacturer for this — usually three or four hours. But after applying the second layer, it is advisable not to do anything for a day. During this time, the composition polymerizes well, and significantly reduces the absorption of the porous base.

- The next stage is reinforcement, and on this occasion we will say this. According to building codes, the screed is reinforced only if its thickness exceeds 2 cm. The block masonry is relatively even, and such errors are quite rare in it. And yet, it is better to reinforce such a wall before plastering.

- We have already said that one of the disadvantages of cellular concrete is its low crack resistance. When a house erected from autoclave blocks shrinks, a grid of small cracks often appears on the surface of the walls. If the walls are covered with dense wallpaper with a deep relief, they will still hide such a defect.

- But on painted surfaces they will be visible, and you will have to make repairs. So it’s better not to risk it, not to try to save on fiberglass, and immediately do everything right. The mesh must be recessed in a freshly applied layer of the solution, only it should not be ordinary, but adhesive.

- If you still have the mounting mixture on which the blocks were glued, use it. If not, you can buy the cheapest tile glue. It is flexible enough and strong to hold the net.

After the fiberglass is smoothed with smoothing movements and the glue comes out onto its surface, it needs to be “combed” with a notched trowel, making horizontal relief strips. When they harden, you will have the perfect base for plastering. By the way, before reinforcing the surface of the masonry from foam blocks, it is advisable to apply an additional thin layer of the adhesive mixture.

Tags: concrete, concreting, concrete material, concrete material