How is facade plaster foam

Expanded polystyrene plates can perhaps be considered the most optimal variant of insulation for external walls. Judge for yourself: it is not blown by the wind, is not afraid of rodents, practically does not absorb moisture. And yet, it has sufficient rigidity in order to plaster the walls lined with it.

How to plaster foam on the outside, and what is the essence of this technology? You will learn about this from the video in this article, which is a clear application to its theoretical part.

The content of the article

Advantages and characteristics of foam

The main advantage of the Penoplex Wall insulation, which you see in the photo below, is its low thermal conductivity, which does not exceed 0.03 W / M * 0C. At the same time, its compressive strength is 0.20 kgf / cm2, and its density is not less than 25 kg / m3.

So:

- Low vapor permeability, with which only materials based on foamed polyethylene (penofol, isolon) can be compared, it allows to omit such a technological operation as installing vapor barrier films in an insulating “pie”. Since penoplex does not lend itself to corrosion, its service life is at least half a century.

- Plate structure homogeneous, with evenly distributed pores, which greatly increases the strength of the material. But at the same time, it can be easily cut with a clerical knife, which makes it possible for any owner to insulate the house with his own hands.

- Due to its high density, wall polystyrene foam does not change its geometric parameters over time, and it can be used as a base for plaster. Its resistance to moisture allows the installation of plates on the facade in any weather.

Penoplex sheets have a standard size of 1200 * 600 mm. In this case, the thickness can vary between 30-100 mm, which determines its price. It is sold in packages in which the number of plates depends on their thickness. The package contains 14 plates 30 mm thick, and it costs 4900-5000 rubles.

What is needed for insulation plastering

For the installation of penoplex some devices are needed, for plaster - others. Therefore, in order to plaster the walls with insulation, a fairly large list is recruited. Consider what is included in it.

Tools and Supplies

To take measurements and control the planes, you need a tape measure; metal square; plumb line; two-meter bubble, and water levels. To prepare the surfaces, use a steel brush, a brush-brush, which is also useful for applying a primer, as well as masking tape and polyethylene, which cover window blocks and doors.

You will need:

- Hammer drill or drill with drills and a “mixer” nozzle, it will be needed both for drilling holes in the walls, and for mixing glue and plaster mixes. A hammer in the form of a pickaxe is used both in the preparation process and for hammering into dowel holes.

- For fixing heat-insulating plates use not ordinary dowel-nails, and dowel-fungi, which are also called dish-shaped. They have a wide flat hat, which does not allow fasteners to "drown" in the thickness of the plate. You should take fasteners with a diameter of 10 mm, but the length of the dowel is selected depending on the thickness of the insulation.Since it must be longer than the thickness of the reinforced material by 30 mm in length, for an insulation with a thickness of 50 mm, a dowel 80 mm long is needed. They sell them in packs of 1000 pieces, although the price goes per piece (8-10 rubles). To twist the dowel cores, you must have a screwdriver, or the appropriate nozzle on the drill.

- Plates are cut either with a knife with a blade at least 250 mm long, or a fine-toothed universal hacksaw. It is also necessary to have two types of scissors in the arsenal: for metal, for cutting the basement profile, and simple, for cutting fiberglass mesh.

Note! A mesh with a mesh of 4 * 4 or 5 * 5 mm is used to reinforce the screed, which will become the basis for the finish layer. It is sold in rolls of 50m, and, depending on the width, costs between 1900-2500 rubles. When buying a mesh, you need to pay attention to the label that says: “facade”, since there are also painting and plastering options that are not suitable for the facade.

- The list of consumables should replenish the base profile, which in this case plays the role of the starting bar, and serves as a support for the first row of insulation. To connect its ends, special docking elements are needed. In order for the mesh adjoining to door and window openings to be of high quality, an adjoining profile is used.

- To protect the corners of the house from mechanical damage plaster corners with a grid, and for leveling profiles along the plane - plastic expansion joints. Since penoplex is not only fastened with dowels, but also sits on glue, accordingly, you have to buy glue for insulation, and a water-dispersion primer that will strengthen the base base.

- But for mounting the grid, you need not glue, but adhesive putty. For the best adhesion of the finishing layer of the plaster, with the reinforcing layer, it is necessary to use a primer - a primer, which should be selected to the type of solution that will be applied to it. By the way, about the decorative layer: most often, the so-called, warm plasters are used for this purpose.

And they are called so, because in them, as a filler, there are materials that are raw materials for the manufacture of heaters. These are balls of foamed glass, perlite, vermiculite - and the same polystyrene, only granular. Such plaster itself is a heat-insulating material, and thereby improves the heat engineering of the facade as a whole.

As for the tools for applying mixtures, you will need a regular arsenal of plasterer: a set of spatulas, including a notched one, by means of which glue is applied to the plates; straight and corner trowels; stainless steel and plastic graters; as well as the aluminum rule, the roller, and the grinding block (see Wall plastering tool: what you need to work).

Tools that are considered to be general construction are available in almost every house, and what is not, you will have to buy or borrow. But about consumables, you can not bother, but buy a warm plaster system from the manufacturer. In this case, you will be offered a kit that has everything from mounting profiles to dry plaster mix.

Plastering process

So, let's figure out how facade plaster foam. As always, work begins with determining the geometry of the facade and preparing the surface of the walls. Those who do not think that it is necessary to spend time are very mistaken.

Where the foundation is not prepared properly, the problems begin in the first place:

- In order for the polystyrene foam boards to adhere well to the walls, there should be no dust, no influx of masonry mortar, or the remnants of old plaster on their surface. Any stains: mastics, rust, mold are also removed.But the surface should not only be clean, but also even.

- This is very important, since on walls having tubercles and depressions, too large joints will be obtained between the heat-insulating plates. So, if there is a curved brick wall at the base, then it should be aligned cement plaster, allow it to dry, and only then proceed with the installation of the plates.

Note! Sometimes masters level the walls by varying the thickness of the foam. But this is not very convenient to do when you need to align the entire facade - and it costs an order of magnitude more expensive.

It should only be borne in mind that if the walls have to be leveled in a wet way, then this must be done in advance, since the plaster will gain full strength only after a month. If the irregularities are not so significant, they can be eliminated by cutting out the linings from the same foam, glued to the back of the plate.

Workflow

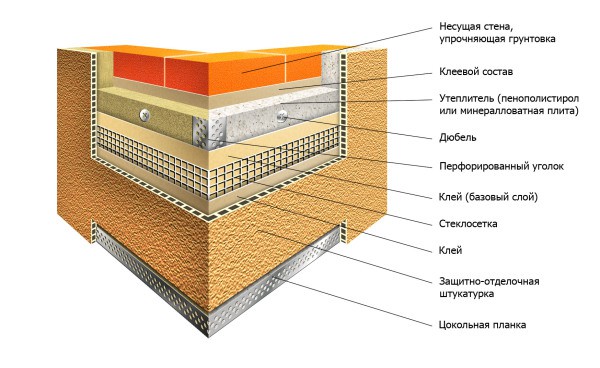

The surface of the warm stucco facade is a multilayer structure, which is commonly called a pie in construction. In it, except for profiles and fasteners, at least seven layers.

It:

- Primer base, which is the final stage of preparatory work

- Adhesive on which the heater is mounted

- Penoplex Sheets

- Glue putty

- Fiberglass mesh

- Primer for maximum layer adhesion

- Finishing layer of plaster.

These operations are performed in the order specified in the above list. As for the installation of profiles, we will talk about them in the course of our story.

Installation of profiles

The whole process of installing a facade insulated for plaster can be divided into several stages. At the initial stage, using the water level, the starting line is beaten, which will determine the lower boundary of the insulated zone.

- After the line is drawn, a basement profile is mounted on it. It has a U-shape - that is, a back and two low sides. On one of them there are holes for fasteners, and the second has a groove and perforation for condensate outflow, and is called a “drip”.

- When installing base ebb tide in corner zones, not pieces are used, but a solid profile. In order to be able to get around the corner, a triangular segment is cut out in it so that the dropper remains intact, and then bend at a right angle. Much depends on how smoothly the base profile is installed, since it is on it that the first row of insulation rests.

- Therefore, during its installation, wall irregularities must be compensated for by special plastic gaskets. The profile is fixed by dowels, selected depending on the type of base. Handle this accessory carefully, trying to prevent its deformation.

- The spacing between the fasteners is 30 cm. The end edges of the profile are joined by connecting elements when docking. If it is decided not to use them, then between the ends you just need to leave a small gap. In no case, the base profile must not be lapped!

The next step will be to install an adjacent profile with a mesh around the perimeter of the openings. It is very convenient when there is a removable strip with an adhesive layer on its surface. You can stick a plastic film on it, which will protect the window unit from pollution. On this, the first stage is completed - further, the installation of plates.

Surface reinforcement

For the installation of plates, either special glue for polystyrene or adhesive putty is used. Many manufacturers in the product line have both. For example, if you use the products of one of the most famous manufacturers of Ceresit, then it will be glue ST-83, or putty ST-85.

- The finished solution is applied with a trowel from the back of the plate only along the edges and two or three pies in the center, or you can make a kind of "beds" with a notched trowel. Installation of penoplex begins from the basement profile, in horizontal rows, with the obligatory dressing of the seams.

- The position of each plate is checked by level, and adjusted immediately, until the glue has hardened. In corner zones, overlap of plates should be performed, as is done in brickwork. That is, the edge of one plate should completely cover the end of the perpendicular to the installed plate. Everything superfluous is cut off with a hacksaw, dust is necessarily removed from the surfaces of the cuts with a brush.

- When bypassing the openings, do not use pieces of polystyrene, but cut out the L-shaped elements from solid plates. Between the angle of the opening and the junction of the elements framing the opening, there must be a distance of at least 10 cm - this will provide maximum crack resistance to the corner zones.

- When installing polystyrene frames around windows, you need to carefully align it along the adjacent profile, bending the mesh outward. Otherwise, there will be no difficulties with the installation of insulation, everything is done in the same way. Dish-shaped dowels are not installed immediately, but only after the glue hardens well and the seams between the plates are sealed.

- If the manufacturer’s instructions do not stipulate other terms, then in good weather it takes three days to dry the adhesive putty. Where gaps of more than 2 mm have formed between the plates, they must be filled with polyurethane foam. When it dries, the excesses that come out are cut off with a clerical knife, and the joints are cleaned with an abrasive bar or grater. Now you can proceed to the mechanical fastening.

Note! In low-rise construction, the following norm is used: four to five dowels per square meter. But in the corner areas of the building, which are more susceptible to wind loads, the number of fasteners increases to seven to eight.

- After all the anchors are installed, proceed to reinforcing the openings. There, if you remember, there is a grid from the corner that needs to be glued to the putty, and you can immediately install corner profiles that also have a grid. Thus, around the openings you get double reinforcement.

- Directly in the corners of the openings, even small rectangles of a grid measuring 30 * 20 cm are glued, which will be additional protection for them. The outer and inner corners of the house, as well as the joints of vertical and horizontal surfaces, are also protected by corners with a grid.

Further, the mesh is mounted already over the entire surface, with the obligatory overlap of the paintings, which should be at least 10 cm. After the reinforcing layer has hardened, its surface is primed, and after drying, finishing plastering is carried out in the traditional way.

The final solution can be tinted in bulk, or you can paint the finished coating on the surface - it already depends on what kind of plaster you choose.