Panels: Features and Installation

Interior decoration can be performed using any modern materials that have a variety of cost and properties. But the most popular is the decoration of false panels, which have a diverse design.

The content of the article

What are false panels and their types

The material is presented in the form of large sheets that have different sizes and thicknesses. Also all panels for home decoration mounted differently.

In this case, it all depends on the type of panel.

They may be:

- Plastic.

- Vinyl.

- Metal.

- Wooden and so on.

The photo shows examples of such finishing materials that have various simulations.

Plastic trim panels for decoration

Among the other finishing materials, plastic has always been distinguished by its practicality and durability. The standard size of the raised panel is 1x2 m.

Exist:

- Stone panels for interior decoration.

- Under a ceramic tile.

- With imitation wood.

- Under a brick and so on.

Plastic:

- Moisture resistant and able to withstand very low temperatures.

- Its surface does not absorb all kinds of pollution.

- Practical and durable.

- Easy to install.

- It has a large assortment of design.

Characteristics:

- Surface plastic panels may be matte or glossy.

- It is easy to clean using ordinary detergent and damp rags.

- It is not recommended to use abrasive products for such work, which can scratch the surface and spoil the appearance of the finish.

- It is worth adding that it does not fade under sunlight and can retain its original appearance for a very long time.

- To work with plastic panels you need to be extremely careful, as breaking its structure is quite simple.

- Plastic is resistant to sources of fire, that is, it is a non-combustible panel for interior decoration.

Note. Mounting the material is very simple, for this the surface is prepared initially.

Surface preparation for the installation of plastic trim panels

The preparatory work is the construction on the surface of a wooden crate.

Tip. There is no need to clean the surface before such an action, since it will be hidden under the finishing material.

The crate is made using:

- Wooden planks and boards of the same thickness.

- Wood screws and dowels.

- Puncher and screwdriver.

- Building level and roulette.

- Pencil

- Saws or jigsaw.

Tip. It is worth considering that work with the use of an electric jigsaw will be faster with less labor.

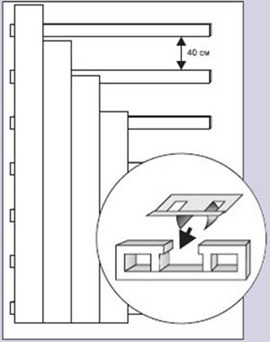

Stages of work:

- Collect the crate directly on the surface. Initially, dowels are mounted on vertical wooden planks.

- Additional elements of the crate are attached to them with screws. Cell size may not be the same size.

- The most important thing is that it is convenient to mount plastic panels on such a frame.

Note. If the building is not insulated, then such work can be carried out during the installation of plastic panels.

For this, standard insulating materials are used:

- Styrofoam.

- Polypropylene.

- Polyester.

Steps for insulation:

- All of them are sold in hard formations and are quite simply cut with the help of a clerical knife.

- Insert their layers of the desired size into the cells of the crate. It is necessary to try so that they are there closely.

This will make it possible not to use building glue to fix them.

Tip. If insulation work is carried out at the time of installation of plastic panels, then their thickness should correspond to the thickness of the frame elements or be slightly less so that the finishing material does not bend on the crate.

Installation of plastic panels on the crate

Plastic panels for home decoration mounted with tools and materials.

Namely:

- Starting strips for plastic.

- Construction stapler.

- Nails are small in size.

- The hammer.

- Level.

- The grinders.

- Pencil and ruler.

Tip. To speed up the process of installing plastic panels, it is best to use self-tapping screws with decorative caps and a screwdriver instead of a hammer and nails.

Installation:

- On the crate at the top and bottom, the starting strip is attached. The first panel is inserted into it and set by level.

After that, one side part is fixed with a stapler, on the other hand, the lock remains open. Self-tapping screws can be used for greater strength at the top of the panel. - The second panel is also inserted into the starting strip and fastened with the first using a special lock. To increase the tightness of the finish, a sealant is used that processes the joints of the material.

Tip. At the end of the finishing work, the outer and inner corners are made of plastic, which are mounted using liquid nails. The video shows an example of editing such material.

Vinyl trim panels and their properties

Vinyl cladding panels for interior decoration have been used for many years. There is vinyl siding and, by its principle, they began to produce whole canvases of material, ranging in size from 1x2 m.

They, like plastic material, have a variety of designs.

There is:

- Brick panel for interior decoration, which is widely used outside the building.

- Under bricklaying or ceramic tiles.

- With imitation of wood cuts or decorative plaster.

- There are also drawings on such panels.

Features:

- Vinyl panels for interior decoration have the same properties as plastic ones.

- They are durable and reliable, the average life of the material is at least 20 years.

- The surface of panels made of such a material is not able to absorb moisture and dirt, that is, it is quite simply cleaned with a damp rag and ordinary detergent.

But here everything will depend on the quality of the surface, which happens:

- Matt

- Perforated.

- Glossy.

- Embossed.

- Flat or convex.

Tip. Glossy or embossed surfaces should not be cleaned using abrasive products that can distort it.

The price of vinyl panels is affordable, which makes the material more popular. It is frost-resistant and able to withstand a variety of temperature extremes.

This allows the use of panels not only inside but also outside the house for decoration.

Installation of vinyl panels

All work on the installation of panels of this type is carried out by hand, since they are nothing complicated. The process is similar to installing plastic panels.

It also requires the manufacture of crates from wooden planks and only the material itself is attached to it.

The same tools are used:

- Screwdriver and hammer drill.

- Self-tapping screws and dowels.

- Hammer, nails.

- Level.

- Roulette.

- Jigsaw or saw.

- Pencil and ruler.

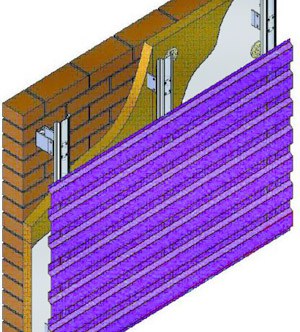

During the work, it is possible to carry out the insulation of the building using polystyrene or expanded polystyrene.

Tip. In order not to carry out such actions, thermal panels are used for interior decoration.

What are they? Their top layer is a vinyl sheet, which is glued by the production method on polystyrene sheets.

That is, it turns out a material that will serve not only as a decoration, but also as a heater.

Metal panels for decorating

Metal has always been considered the most durable and reliable material. Panels made from it for interior decoration can not be found often.

This material is mainly used for outdoor work, as it has excellent technical properties and characteristics.

Panels can be:

- Aluminum.

- From a simple metal sheet.

Characteristics:

- Sheet metal panels have a variety of shapes and designs. You can find brick panels for interior decoration of the building, which are used in bars, cafes, saunas and other public places.

- The metal does not absorb moisture and does not deform under the influence of sharp temperature drops and direct sunlight.

- It withstands virtually any load.

- The only thing to consider is that metal panels are susceptible to corrosion. They appear due to improper use of the material (moisture gets under it).

- Accordingly, metal panels need to be fixed in a certain way. For this, there is a special instruction for use and installation.

Aluminum panels for interior decoration are more practical than simple metal. They do not corrode, which means you can use them for an unlimited period of time.

The scope of their application is similar to the previous form.

Installation of metal trim panels

If you are installing panels of metal sheet, then you will not be able to perform all the work yourself. The panel has significant weight.

But, it all depends on its size. It is made, as a rule, of thin metal.

There are thicker plates, which in most cases are used for outdoor applications.

Installation:

- Aluminum panels are easier to mount, as they are quite lightweight regardless of size.

- The material is attached both to the surface and to the crate.

Tip. If you install metal panels directly on the surface without making the crate, then the surface itself must be stone, which will enable it to withstand the weight of the material. You can also make reinforcement work on it using a reinforcing mesh.

- Metal panels have special holes for fastenings. In the process of work, screws with long legs or a dowel are screwed into them.

This choice depends on the weight of the material. - Panels are fastened, usually joint to joint. Such actions do not allow moisture to penetrate under the finishing material.

All joints of metal panels can be treated with a sealant that does not have water permeability in its properties.