All about how to panel

Installation of cladding panels is almost always carried out according to the system of ventilated facades, on the frame. Naturally, in each case there are technological nuances.

Both the frame structure and the fastening of the facing panels depend on the size and configuration of the elements, as well as the types of locking joints provided by the manufacturer. In this article, we will offer you an overview of the facing options offered to us today by the construction market, as well as outline how the panels are installed.

The content of the article

Panels for facades

Paneling today is the most promising and cost-effective type of finish. And this applies not only to facade works, but also to interior design.

After all, what is the most important thing in the decoration? Firstly: aesthetic effect, and secondly: durability of the cladding.

If we talk about the exterior finish, then, to these two criteria are added and others - low weight and low price of the material; the ability to insulate walls in parallel; as well as a reduction in construction time, achieved through simplified installation technologies.

So:

- Facing panels for exterior decoration, fully meet all these criteria. That is why, they are used not only in low-rise construction, such as, for example, decorative stone, front brick, or thermal wood.

In the construction of frame high-rise buildings, such finishing is generally the only possible option to get a beautiful and warm facade - such as in the photo below.

- Can you imagine how long it would take workers, lifting mechanisms and time to clad the exterior of a 16-story building with several porches, say ceramic tiles, and how much would it cost?

And so, there is a panel with facing tiles, which is a heat-insulated module with a finish. A wonderful appearance is the most valuable quality of this material. - Of course, insulated facing panels for tiles is not the cheapest option for facade decoration, as they use natural clinker and stone tiles in their production. But on the other hand, it is not necessary to use heat-insulating material, the panels are mounted quickly, saving the budget and reducing the time for putting the house into operation. And this more than compensates for the cost of purchasing thermal panels.

- By the way, thermal panels are the only option that can be mounted not only in a frame, but also in an adhesive way: on brickwork or on a bar. There are many other types of panels.

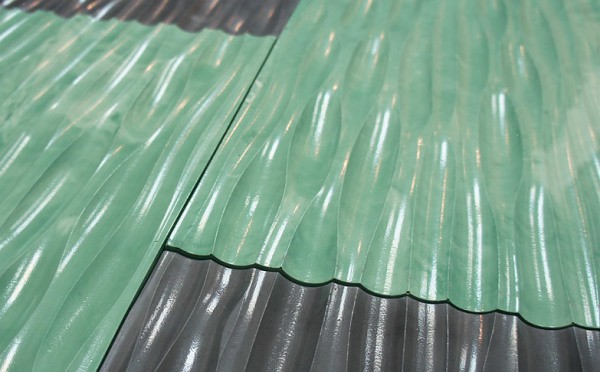

According to the type of raw materials used for production, they can be divided into metal, wood, cement and polymer. - Moreover, almost all of them are composite. This means that in the manufacture of several types of materials are assembled.

This is done in order to give one of them the properties of the other. The main requirements for facade materials are moisture resistance, resistance to temperature extremes, ultraviolet. - Only polymers possess these properties, therefore, they are used both as the main raw material for the production of facing and as an additive to natural raw materials. Expanded polystyrene panels for cladding, most often imitate rubble stone, and are used mainly for cladding foundation walls.

- Such a finish allows them not only to decorate, but also to insulate at the same time. On the pile foundations, with their help, a false base is arranged.

Density facing panels here plays an important role, since polystyrene foam, it is still not metal or wood. PPP is divided into four density categories, and the highest is 50 kg / m3.

This type is used for the manufacture of cladding panels, as they must withstand wind loads.

Other polymers are also used in the production of facade panels: polyurethane foam, polypropylene. In particular, they serve as insulation in sandwich panels, thermal panels, as well as aluminum sheet panels of the Alucobond type.

As additional raw materials in the production of composite products, polymer resins are used. They give natural materials characteristics that are not inherent to them.

Polymer concrete

The market of finishing materials is regularly updated with new products, among which polymer concrete panels occupy a leading position. The name speaks for itself.

They include cement, quartz flour and sand, polymer additives, dyes. Using special forms allows you to get products with any relief, including stone facing panels.

So:

- In fact, these are 3D panels that can be used not only for facade cladding, but also in interior decoration of administrative and industrial buildings. Polymer-concrete facing panels, the sizes have standard: 600 * 600 mm; 600 * 300 mm; 600 * 400 mm.

Mounting holes may be provided for them, and sometimes decorative screws and joint sealant are included. - In some embodiments, the fasteners may be hidden. If the manufacturer's instructions provide for the installation of a facing panel with a gap, a steel tape with a polymer coating is placed under the plates. Its color may be contrasting or match the color of the lining.

How facade panels are mounted

Panels made of polymer concrete, as, however, and many other options: porcelain tiles; metal cassettes; fiber cement and wood-polymer panels - can be mounted both on a wooden frame and on a metal one. But if you take into account that the service life of the wood does not correspond to the same indicator of the cladding, it is better to use an aluminum profile to install the crate.

- Its price is higher than a wooden lath, but you do not need to think about protective impregnation, which also does not give long-term guarantees. In indoor conditions, wood lasts longer, and on the street, it needs to be treated with an antiseptic from time to time.

How can you do this without removing the lining? A similar finish is done once and for all. For those who decide to do the work themselves, it would be nice to watch the video first.

Here is a list of materials that will be needed to install a ventilated insulated facade on a metal frame:

| Type of material | His appointment |

| L-shaped profile | With its help, the facing is docked to door and window openings. |

| Z-profile | Used to install crate belts, provides maximum rigidity of the entire structure. |

| T-profile | It plays the role of a guide. |

| Brackets | Provides the necessary indentation of the cladding from the base |

| Klyammery | Special mount for cladding panels. With it, the cladding element is held in position. |

| Thermal insulation material | As a heater for ventilation facades, it is better to use PPS boards or mineral wool with aluminum coating. |

| Plate Dowels | Fixture for insulation |

| Dowel nail | Wall mounts |

- The design of the frame has differences, depending on the configuration of the facing elements. When mounting long, narrow panels, crate belts are mounted in only one direction.In this case, the profile should be perpendicular to the panels.

- When facing is made by sheet or modular panels, the profile is mounted and transversely. The step between the elements of the frame should correspond to the size of the decorative material. If the sheet is large, it should rest on the frame a few meters.

- Before you begin installing the frame, you need to take care of the facade waterproofing. The choice of technology for its implementation depends on what material the building is built from.

For brick and concrete, it is better to use hydrophobic impregnation, if the house is wooden, the walls will be protected by the roll membrane much more effectively.

- The installation procedure is as follows. With the help of the level, a horizontal line is drawn along the lower perimeter of the walls - a start profile will be mounted on it.

Then the grid grid is marked, and brackets are hung at the intersection of the lines. Now mount the "pie filling."

If the waterproofing is coated, then it is done in advance, and if it is rolled, then after installing the brackets, glue. - After it, a heater is laid, the installation of which is carried out from the bottom row, based on the starting profile. The plate in the center and edges is greased with glue, pressed to the base, and then fixed with a plate dowels.

Where the thermal insulation is prevented by the bracket, a slot is made under it. If necessary, the material is carefully cut at the edges, but so that there are no gaps between the plates. - And so, with the heater finished, not forgetting about the ventilation gap. Now you can proceed with the installation of longitudinal and transverse profiles.

They are installed in the grooves on the brackets and fixed with special rivets. The vertical position of the brackets is immediately adjusted using the level.

Installation of cladding panels starts from the bottom row, from the corner. In order to beautifully design the corner zone, many types of cladding provide for the presence of additional elements. In this case, the installation begins with them.

Interior options

Panels also play an important role in interior design. As for living quarters, then preference is given to natural materials: gypsum, wood, bamboo, fabrics and leather.

In such interiors, panels are used precisely for design, as an accent element. In our example, you see the facing panels for rooms, with a three-dimensional relief, made of gypsum.

So:

- For lining the vestibules of public and administrative institutions, entertainment, shopping and sports complexes, cheaper versions of polymer or composite panels are used for this purpose. For example, wood-polymer facade panels can be perfectly used for facing office interiors.

- In the previous chapter, we talked about polymer concrete. So, it can also be used in the design of rooms.

Such panels can be clad in the bathroom or work wall in the kitchen. If, for example, you have to finish and zoning a studio apartment, you can order a custom-made decorative concrete polymer partition.

- She will not need finishing, and in the room she will look something like in the picture above. Even if your partition is brick or gypsum, it can be lined with 3D effect panels.

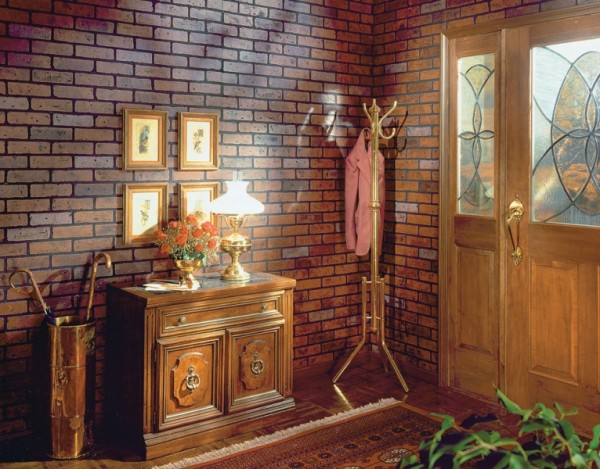

Such a solution is suitable for a room for any purpose - it is only important to combine them correctly with other types of finishes. - By the way, the now fashionable facing of one wall under a brick can also be done with the help of facade material. Use thermal panels for this, and you will get not only the desired aesthetic effect, but also additional sound and heat insulation of the room.

This is especially true for country houses, which are heated irregularly. In our example, you see a similar option wall decoration in the hallway of a private house.

- Well, and where without such an option for interior decoration, such as solid wood panels or laminated MDF. Such interior decoration is carried out within the framework of many architectural styles: English, classical, neo-classicism, modern, art deco, Provence. This option is often considered office, for the reason that wood panels are often used for wall cladding cabinets.

- This is not entirely true, because the panels are different. For offices, options with an unassuming geometric pattern around the perimeter are more suitable - so that nothing distracts from work. In the design of respectable interiors use panels with carvings, inlaid, gilding, they can also be covered with leather or fabric.

Modern interiors are often decorated with sheet panels. These include MDF, veneered with valuable wood veneer, and gypsum, with vinyl or aluminum coating, made in the factory.

And if gypsum and bamboo relief panels are mounted on glue, then all other types - on a wooden crate. Such work can always be done independently - there would be a desire!