Do-it-yourself installation of a frame for drywall on a wall

Even a child knows today what drywall is and how to work with it correctly. This material is simple, but at the same time reliable and durable, and that is why it is so popular. But if, as a rule, there are no problems with fastening the sheets, then mounting the frame under the drywall on the wall often causes some difficulties for those who are going to do the repair themselves.

In this article we will talk in detail about how to cope with this seemingly difficult task, and by the end of the material, you will realize that your fears have been greatly exaggerated.

The content of the article

Preparatory work

Installation of the frame for drywall on the walls, as well as any other repair, begins with preparation. This applies to both surface preparation, and tools and everything you need.

Professional craftsmen know that sometimes it can take a lot more time to search for a pencil or tape measure than for the job itself. In addition, it is likely to undermine your nervous system in the process of such searches.

To avoid this, we will give you a list of everything that you may need in order to make a frame for a drywall wall quickly and without too much fuss:

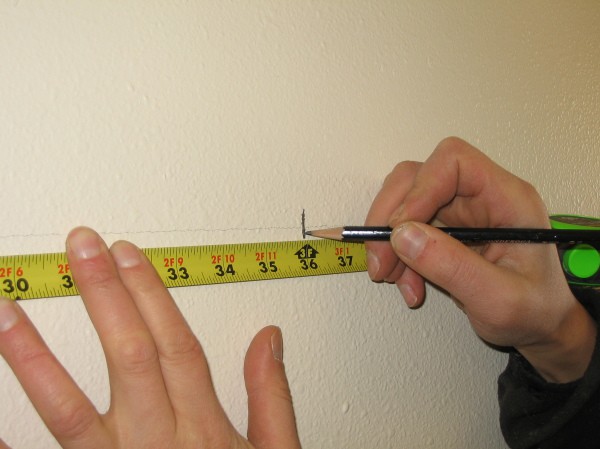

- Pencil and tape measure. The first tool that should always be at hand. during installation, we will need it repeatedly, so we put it in the most prominent place, and even better in the pocket of our clothes.

- Building level. Without this tool, making a wall frame for drywall is simply not possible. Unless of course you plan to do everything crookedly and untidily. Do not plan, then prepare several levels of different lengths and with different eyes at once.

- Hammer. It’s not even worth mentioning that without this tool, not a single repair is complete. Ideally, if the hammers will be several different sizes, from a small boot, to medium sizes.

- Hammer and drill for him. In some cases, when, for example, the walls are built of wood or aerated concrete, you can use a simple drill that will do fine with these materials. If your walls are built of brick, then you just can not do without a punch.

- Screwdriver. In principle, you can replace it with the same drill, but working with it is not so convenient, besides, screwdrivers work from batteries, which means that the wires will not bother you. Also, a bit is needed for a screwdriver - a nozzle in the form of a short Phillips screwdriver, with which screws are screwed.

So, the whole tool is assembled, and lies at hand, and it's time to prepare all the necessary materials. We will not give the quantity, since the calculation is always carried out individually, so we will give only a list.

Advice! Ideally, to apply the markup, use a modern laser level, which will not only simplify the work, but also significantly accelerate. Of course, pleasure is not cheap, but you can search in your city for a company that rents construction tools. You pay a little, but it will be much easier to work.

So, here is the list of materials that we will need in order to build a frame on the wall under the drywall:

- Plastic dowels. Always take them with a margin, since it is almost impossible to calculate the exact amount.

- Plumb. Metal plates with holes that hold the guides away from the walls.

- Crabs. Fasteners that fix the guides at their intersection with each other.

Well, and finally, the material itself, from which the frame will be caught.

There are three options to choose from, each of which has its own characteristics:

- Wooden block. The cheapest and short-lived material. It is believed that the walls of drywall on a wooden frame, serve much less, and this is due to the characteristics of the tree, which absorbs moisture and is able to deform with time.

- Metallic profile. What is called - cheap and cheerful. This frame has only one significant limitation - it can not be used in rooms with high humidity. The metal quickly rusts, and unpleasant yellow spots can eventually appear on the surface of the finish, especially if you use painting or natural wallpaper.

- Galvanized profile. The most expensive, but at the same time high-quality material, the price of which is fully justified, it can be used in any room. Zinc coating does not allow the metal to rust, and this frame serves much longer.

Which of these materials to choose is your business, but we recommend that you do not save on this, and immediately take a profile with a galvanized coating so that after a couple of years you will not encounter problems that are very difficult, and sometimes impossible to solve without radical intervention. So, the materials are selected, the tools are prepared, which means that you can proceed to the first stage of our work.

Marking

Before you make the frame for drywall on the wall, this same wall must be marked. The quality of the finish as a whole directly depends on how smooth and high-quality the markings will be applied, so we have patience, pick up a pencil and a tape measure and go!

So, first of all, we need to catch the level of the walls. To do this, take a tape measure, and from the corner we retreat a few centimeters out. Now, connect the two labels on the floor. At this point, the main mounting profile will be held.

Now, the same thing needs to be built on the ceiling. We got two lines that should go exactly parallel to each other.

Now, we retreat from one of their walls exactly 2050 millimeters. This is the standard size of the drywall sheet, and it is necessary that its edge lies exactly in the middle of one of the profiles of the frame.

Further, we retreat the same distance, and so on until the wall ends. We now have places where the guides will be without fail, but the distance is too large, so we divide it into sections of about 40-60 centimeters. This is quite enough so that the sheet of drywall does not sag, and it was hard to break it.

Everything is ready. Now we have a number of vertical stripes, but we need to determine the places for fastening the plumb lines. To do this, we simply divide the height of the wall in half, and put a mark in this place. Now, we divide each segment in half, and so on, until the distance between the nearest points comes close to the mark of 30-60 centimeters.

Important! The walls of drywall whose frame was assembled without strictly observing the level can subsequently turn out to be very curved. Drywall easily bends to the desired position, but will be in constant tension, and sooner or later will burst. That is why it is impossible to neglect this seemingly insignificant stage of decoration.

At these points, we will not only have plumb lines installed, but also horizontal guides that will pass, so it is so important to strictly observe the level at all stages of the wall layout.

We mount the frame

Next in line is the dirtiest and loudest stage, and if you do not want to become enemies with your neighbors, do not do this work early in the morning, late in the evening or on the weekend.

So, we take a puncher in our hands, and drill the holes of the required depth at all the marking points that we set. It is important to accurately capture the drilling depth, since if it is insufficient, the dowel simply will not fix the plumb line, and pulling it out of the wall will be very, very problematic.

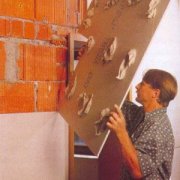

Now, using dowels, fastens the plumb lines, and bend their edges perpendicular to the wall. That's it, the preparatory work is over, and you can proceed to the fastening of the guides.

First of all, we fix the main profiles to the floor and ceiling. The remaining elements of the crate will be inserted into them, therefore, the stronger the fasteners, the better.

We insert guides into the fixed profiles, and align them to the vertical level. This stage should be taken very seriously, otherwise we will have to cut each sheet of drywall later, and this is a very long lesson that can be completely avoided.

The profile set according to the level is fixed with self-tapping screws to the previously bent plumb bob. And we repeat this procedure with all segments of the crate.

Our wireframes drywall walls almost ready, it remains only to expose horizontal elements. To do this, simply attach the profile to the crate that we already have, and mark the points of contact with a pencil. Further along the marks, we make cuts with scissors for metal, and we fix the profiles, guided by the readings of the level.

That's basically all, the frame is ready, and it remains only to fix the drywall and make the main finish, but this is a topic for a separate article.

And in conclusion

Well, here we’ve figured out how to make a wall frame for plasterboard. Apparently, there is nothing complicated or impossible here. The process is more like assembling a children's designer, only the details are larger and heavier.

The most important thing is not to be afraid to take up work, even if you do not have the relevant experience, and our site will be happy to answer any questions that you may have in the process. Frameless installation of drywall on the walls is not difficult, but responsible. Take a look at the photo and you can get to work.