Arrangement and decoration of floors in a wooden house

The interior decoration of wooden houses can be even more diverse than in apartments, brick and block houses. After all, supporting structures help to create an interesting and memorable interior in such a house.

A beautiful floor can also help, but in order for it to be not only beautiful, but also durable, it is necessary to perform it in strict accordance with building codes. And our little instruction will help you with this.

The content of the article

Ground floor device

Foundation construction wooden house such that concrete piping is done only along the outer perimeter of the house. Internal walls and partitions are supported by a columnar foundation made of brick.

So:

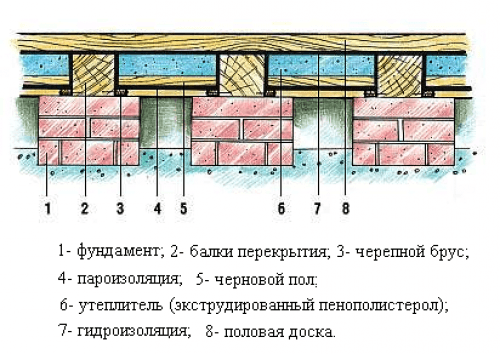

- At the base of the foundation, in this case, there is compacted soil over which a sand cushion is laid. We will consider the option of installing a subfloor in a house that does not have a basement.

When a spacious basement is planned in the house, the construction of the foundation should be completely different. - And in our version, wooden beams with a section of 150 * 150mm, or, as they are otherwise called, logs, are laid on a concrete base. The step between them should be at least 0.8 meters.

In the event that the distance between the outer walls exceeds four meters, there is a risk of sagging beams, and then their brick pillars are an intermediate support. - Further, cranial blocks are nailed to the lateral lower part of the lag, on which boards or sheets of chipboard, which are a rough floor, will rest. The next stage is the installation of a waterproofing layer.

Attention! All wooden elements of the subfloor must be treated with an antiseptic primer on all sides.

This is necessary to prevent deformation, moisture and drying of the tree. It is necessary to process those parts of the foundation on which the beams are based.

- As a waterproofing layer, it is most convenient to use any rolled material. In addition to the well-known ruberoid, there are many of their varieties: PVC membranes, hydroisol, bitumen-polymer films, polyisobutylene. They overlap them, slightly bending upwards along the perimeter.

- When the subfloor is carefully laid, the turn comes to install insulation, which will fill the cells between the logs. The most inconvenient option in this case would be a roll insulation, because it would have to be cut.

And this work is not only superfluous, but also requiring caution and protection of a person in contact with mineral wool. - It is much easier to use bulk materials: granular penoizol or polystyrene foam. The same materials are sold in the form of plates, and their price is quite affordable even for the most modest budget.

After installation, any insulation must be covered with a vapor barrier film, which will prevent the accumulation of condensate on its surface.

- To reduce the time it takes to complete work, purchase a film, and glue for it, you can purchase a modern insulation, the top layer of which already has the necessary coating. This is usually a layer of foil.

And to lay such a heater you need a foil layer inside the room. - The height of the beams and the thickness of the insulation must be calculated so that after installation of all layers, a small ventilation gap remains.It should be formed between the vapor barrier and the floorboards.

The clearance at the boardwalk should be along the perimeter of the walls, it is necessary for the expansion of wood. - By the way, if you do not plan to make a wooden floor, but want to finish the flooring in a wooden house with a tile, instead of boards it is better to mount magnesite or cement-particle boards. They are an excellent basis for any finishing coating, and also provide additional heat and sound insulation.

Before laying the tiles, their surface must also be primed to avoid moisture absorption from the adhesive solution. If you decide to do all the work on the device of the floor with your own hands, keep in mind that there are many nuances that you need to know about.

Therefore, first watch the video - this will give you more information than any written instruction.

Floor on the floor

If the wooden house has two floors, or an attic, then the floor of the upper room will be performed a little differently. The floor slabs that we used to see in concrete houses are not here, but there are wooden floor beams.

So:

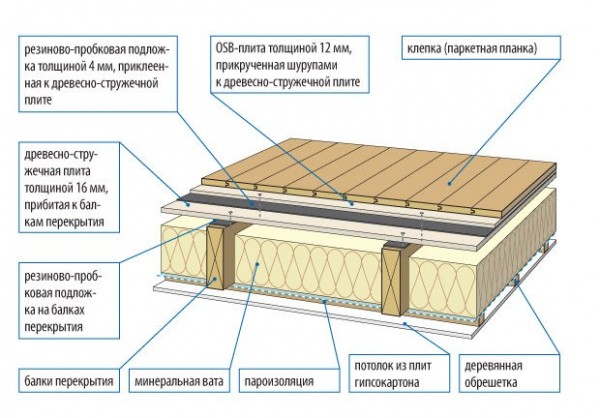

- On these beams the ceiling of the lower floor and the floor of the upper floor will be mounted. The photo below shows an approximate diagram of such an overlap.

- So: first, the ceiling of the first floor. The space between the beams is filled with a plate insulating material, the dimensions of which are selected so that its width by a centimeter or two exceeds the step between the beams, and the thickness is slightly less than the height of the beam.

- The lower edge of the insulation should be flush with the lower edge of the beam, and the ventilation gap will be in its upper part, under the floor of the upper floor. When the insulation tightly enters the space between the beams, it does not fall out during installation.

- Its fixation is carried out by stuffing on top of the insulation of a wooden crate of battens. Do not forget about vapor barrier!

Further, on this crate, you can lining the ceiling, drywall, any panels or make a suspended ceiling. - Now go to the floor of the upper floor. For further work, you will need to purchase a rubber-cork substrate.

First, cut strips from it along the width of the floor beams and fix them on glue. They will serve as a kind of shock absorber for chipboards, not less than 15 mm thick, which will be nailed to the floor beams.

- After installing the chipboard, the substrate will need to be spread over the entire floor area, OSB boards or thick glued plywood will be mounted on top of it. This material is much more durable than chipboard, and is not subject to deformation.

And you can use cement-bonded particleboards, depending on the floor finish.

The result is a multi-layer, sturdy construction that will withstand loads from the weight of furniture and people. Work on the installation of the rough floor, can be performed directly in the process of erecting walls.

Well, the finish coating - after it is completed home decoration.

Finish finish

There was a time when a carpet or rug on the floor was a mandatory attribute of the home. Under it, the floor surface was practically not visible, therefore, decorative coatings were not given much importance.

- Now everything has changed: floor coverings are so varied, practical and beautiful that it’s never occurred to anyone to hide such a floor under a carpet. It is not difficult to select materials for the interior decoration of a wooden house.

- It is logical if the owner of such a house wants to have all the surfaces of the house made of wood, including the floor. In this case, there are three options: parquet, plank flooring and laminate, which we will tell you about.

Parquet floor

This type of flooring is rightfully considered the most elegant and respectable, because parquet boards are made only from natural wood. In this case, various species of wood are used, including valuable ones: beech, rosewood, Karelian birch, walnut, mahogany and ebony.

So:

- When installing the floor, you can alternate planks of different types of wood, and lay them in different directions. But experts must do this.

Especially if there are parquet boards with a pattern, and you need to assemble panels from them. This is the so-called art parquet.

- This floor can be done in the living room, lobby, office or dining room. But such a magnificent floor does not have to be on its own.

Its color and pattern must be in harmony with the general style of the interior and the materials used for its design. - And if you focus on the surface of the floor, choosing a picture like the one above, the interior decoration of the wooden house should be more modest and not attracting attention. If you have followed the technology and design of your floor such as shown in the previous chapter of our article - you have an ideal base for laying parquet.

- Parquet boards are attached to this base with glue and are additionally fixed with self-tapping screws. Their competent laying guarantees more than twenty years of operation, especially since the top layer of the tree can be updated from time to time by cycling.

Parquet can be: both piece and type-setting, and panel board. - In order for the parquet to serve for a long time, it is necessary to observe the temperature regime in the room from +18 to +22 degrees Celsius. At the same time, the level of humidity should not exceed 60%, and be less than 40%, for which room steam humidifiers and split systems are used.

Finishing the surface of the parquet consists in covering it with a special varnish. The composition of the parquet lacquer includes a substance called "aluminum oxide", which greatly increases the service life of the floor.

The more layers of varnish applied to its surface, the less parquet will be subject to abrasion. Therefore, even more than ten layers of varnish can be applied to it.

Parquet board

Some finishing options inside a wooden house may look more harmonious if you choose a parquet board as a floor covering.

What is it:

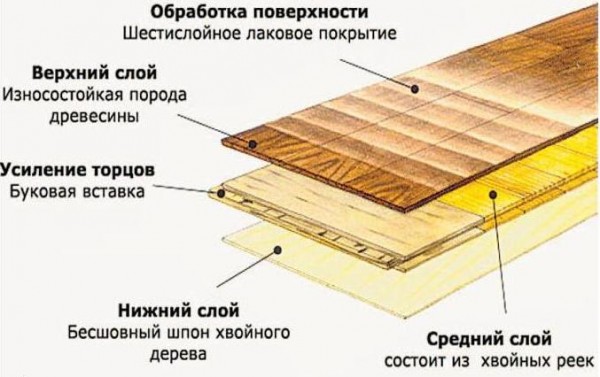

- This board, which is a kind of parquet, is made from natural wood. But this is not an array of wood, as is the case with parquet, but a kind of three-layer construction, the top layer of which is veneer made of valuable wood varnished.

- The appearance of such a board made the process much cheaper, because not everyone can afford such a pleasure as parquet made of solid wood, and even valuable species.

- And on the floorboard, the lower part is made of cheap raw materials. Its larger size, in comparison with piece parquet, and convenient lock fastening, allow laying flooring in a short time.

Moreover, such a board does not need to be varnished, and it is also not necessary to cycle during operation.

- There are several types of flooring: one, two, three and four strip. The latter are the cheapest option, since narrower strips of high-quality veneer are used for their face coating, and in fact production waste.

Such a board is mounted quite simply and quickly, and it is not difficult to dismantle it if necessary. Using a parquet board in rooms with a large area is much easier.

Due to this, finishing the interior of a wooden house will not take as much time and effort as it takes to lay typeset parquet.

Laminate

Laminated flooring is perhaps the most affordable option. Their multilayer structure is a bit like the structure of a parquet board, but the raw materials for their production are completely different.

So:

- Here, neither veneer nor solid wood is used at all. The basis of the panel is fiberboard. A layer of moisture-proof paper protects it from below.

On top is a moisture-resistant film, decorative paper with a wood pattern and a layer of melamine or acrylate resin. - This structure may vary slightly from manufacturer to manufacturer. There are many types of laminate. After testing, which includes more than 15 tests, each of them is assigned a class that determines the possible operating conditions of this product.

- Laminate flooring, of course, can not be compared with chic parquet. But if you, nevertheless, want to cover the floor with a carpet, then special beauty is not required from him.

Perhaps the main decoration of the interior will not be the floor, but the ceiling.

In our example, on the ceiling, sheathed with an ordinary clapboard, made art painting. Variants of the interior decoration of a wooden house may include other types of decoration of wooden surfaces: carving, inlay, artificial aging of a tree.

As well as coloring not only with varnish and stains, but also with mother-of-pearl and decorative paint - there is nothing to count. So go ahead, think, do it yourself. And we can only wish you success in this!