Cladding the ceiling - all the main "tricks"

Wood is a natural material that man has long used to build and decorate his living quarters. Wooden coating is not only beautiful, but also environmentally friendly.

Let's look at how you can finish the ceiling in the room. If you like natural materials, clapboard ceilings are your option.

Unlike its plastic and hardboard counterparts, the lining is not afraid of either heat or frost.

The content of the article

- Classes and types - choose the right material

- Installation - basic rules and subtleties

- Acclimatization is very important

- Lathing - only correct execution

- Vapor barrier is another important slogan.

- Joints - the choice is yours

- Mounting Methods - Kleimer

- Nails - the main disadvantages

- Screws - the main problems and solutions

- Screws - 0.5 mm matters

- The main advantages of screws

- The right material is not a hindrance to the screw

- Mount - quality and reliability

- Need some advice? - contact

Classes and types - choose the right material

Today we will consider the option ceiling finishes lining, how to lay it and fix it correctly.

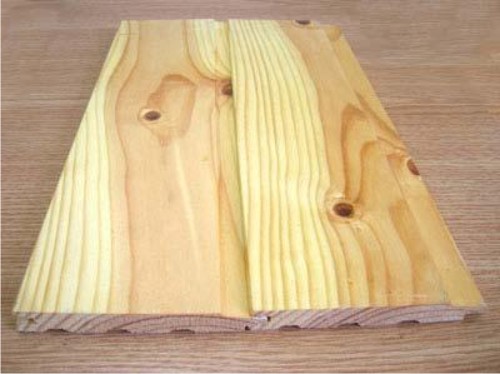

Our reference is lining, this is a cut board with a thickness of not more than 20 - 22 mm. It is used for interior and exterior decoration of houses and premises.

Many may think that if the lining is just a board, then to purchase and nail it to the ceiling will not be difficult. He is very mistaken.

If you decide to decorate your home with certain material, you should know as much as possible about this material.Must choose it correctly and use it correctly.

Right choice

The very first step is to choose the lining. It is important to know that at the very beginning this finishing material is not processed with anything and it can be coated with any color.

If you want to leave a natural, natural color, you can cover the lining with a stain, which only emphasizes the structure of the tree, can be treated with paint or varnish. It is important - if the tree is not processed, it will deform when dried.

When choosing a lining, pay attention to the back side, there should be two gutters. These gutters are necessary for ventilation, they prevent the material from being led in the future.

Classes - what is important to know

Lining is divided into classes.

Exist:

- Class A

- Class B

- Extra Class

These classes differ among themselves in the presence, quantity and quality of knots.

The largest number of knots is in class B. It is also worth knowing that there are “non-living” knots in the material of this class that can fall out during operation, which will lead to the formation of holes in the surface.

Options for finishing ceilings with a lining of this class are simply undesirable.

In Class A material, there are far fewer knots and they are all “living”. These knots do not fall out during operation; accordingly, holes are not formed in the coating.

This class can be used for the ceiling.

If you want to close your ceiling without a hitch, then you need the Extra class - euro lining.

Extra class has no knots and is designed for bath finishes and saunas. The absence of holes after knots will protect the room from heat loss.

If you have a question - how to finish the ceiling with eurolining? We can answer the following, there is no fundamental difference in the installation, so we will not focus on this class, but consider the general rules and principles.

Steam room - a special choice

If you plan to finish the steam room, we advise you to use aspen lining:

- This lining is not afraid of high temperatures and humidity.

- It is clear that depending on the class, the price of a lining is a significant difference.

- Therefore, choosing this material for decoration, first of all pay attention to the class and only last but not least the price.

- Otherwise, the pursuit of low prices can cost you dearly in the truest sense of the word.

- Alteration will entail additional costs for materials and work.

Processed, not processed - what to prefer

On sale there is processed and not processed lining.

Our advice is to purchase unprocessed.

Unprocessed lining can easily be repainted in the desired color, or leave your own, natural.

As a rule, a certain amount of this material with processing is on sale, during the production of which the processing technology is grossly violated.

When storing material, many sellers store it incorrectly. This is not only in the temperature regime.

Usual negligence, laid not evenly or on an uneven surface and the whole batch ultimately turns out to be crooked:

- If the untreated lining is allowed to lie down in the room, in most cases it is straightened.

- Painted, as was the curve, remains so.

- In the future, during installation this will create additional problems.

Installation - basic rules and subtleties

Lining you have chosen. Now it remains to deliver it to its destination and install.

You will undoubtedly cope with the delivery yourself, but before installing, you need to know some rules.

Acclimatization is very important

After the material has been delivered, do not rush to start installation immediately. Cladding ceilings involves a certain acclimatization of the material to the room.

Our advice - after delivery, allow the material to lie down in the room in which the installation is planned for at least 48 hours.

This operation is necessary so that subsequently the boards do not lead after installation.

Lathing - only correct execution

The installation of the lining begins in the device of the battens from the rails, to which the lining itself will subsequently be attached:

- The slats of the frame are cut into pieces of the required length so that they are located from wall to wall perpendicular to the direction of the lining itself.

- The frame rails are screwed to the bearing beams of the ceiling or to the floor slabs. It all depends on the material of the ceiling of the room itself.

The distance between the rails is selected depending on the size of the purchased lining.

Let's mount the crate. Regardless of whether installation is carried out in a brick, concrete or wooden house, the first step is to determine the lowest point of the ceiling.

On the pages of our resources describing the options for finishing ceilings with panels or drywall (seePlasterboard ceiling decoration - how to do it right), described in detail how to do this, so we will not be distracted.

So:

- The lower point is determined on the basis of it, the installation of the crate is carried out.

- When installing each rail, carefully monitor its horizontal location using the building level.

- If your ceiling leaves much to be desired, place pieces of battens or boards under the crate. Use for fastening self-tapping screws of the appropriate length.

In this case, the self-tapping screw should pass through the rail and through the lining.

The entire final result of the work will depend on how you fix the crate exactly. But what if the height differences on the ceiling are very large?

In this case, suspensions should be used. The suspensions are ordinary, which are used when installing the profile for drywall. Convenient, reliable, high quality.

Vapor barrier is another important slogan.

Now you need to install a vapor barrier.

So:

- If you have wooden beams, shoot it with a construction stapler. If the surface is concrete, glue it using "Heat Glue".

- Joints of vapor barrier must be overlapped. The overlap is 100 mm.

- Joints along the length must be glued with double-sided construction tape.

Our advice - before installing the vapor barrier, carefully read the instructions to install it on the right side. It is very important.

Joints - the choice is yours

You can proceed with the installation of the lining itself.

If the installation is carried out in a wooden house and at the same time the house is new, not standing up, leave a gap of 15 - 20 mm between the lining and the walls. This clearance is necessary in order to compensate for the shrinkage of the house, which occurs within 2 to 3 years after construction.

There are two ways to dock the lining along the length:

- Butt to butt

- Staggered

Important - all wiring must be completed before installation.

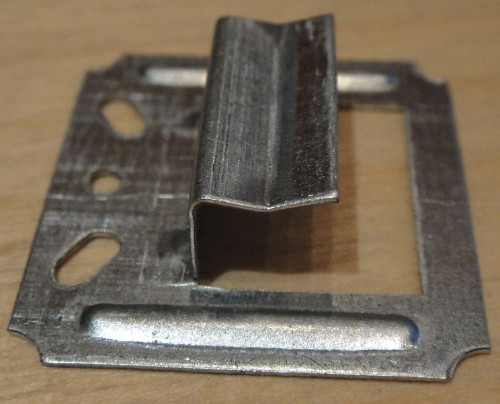

Mounting Methods - Kleimer

It is necessary to say a few words about the mount. To fix the lining, you can use self-tapping screws, nails or special fasteners - kleimers.

- Kleimer slides into the groove of the lining and gently knocks out until it fully adheres to the board.

- Kleimer can be attached to the crate using nails or self-tapping screws.

If you will be using nails, use a dobnik. This will protect the edge of the board from accidental hammering.

Just put the finish plate on the hat of a half-clogged nail and hit the nail with the hammer with the hammer to the end.

Nails - the main disadvantages

The same thing must be done if the fastening is carried out using nails without using a clamp.

Using nails is the so-called traditional way. The nail is inserted into the groove at an angle of approximately 45 degrees and is hammered into the middle with a hammer.

Next, a dobnik is inserted and the nail is hammered to the end.

What is the disadvantage of this method? As can be seen from the figure, even the use of a damper cannot prevent deformation of the groove edge.

Many may disagree and say that this deformation will not be visible. But practice shows that during operation the hammer jumps off the damper and crushes the already visible part of the board.

Some craftsmen even make special metal devices to protect the board from accidental damage. The device is installed on the board and acts as a shield, after the nail is hammered, it is removed and rearranged in a new place.

Another disadvantage of this method is lubrication. As you know, nails go on sale in grease.

During work, hands and gloves get dirty very quickly. Having touched a clean, unprocessed board with such a hand, it is very easy to spoil its appearance.

It is necessary after, using sandpaper, to sand the stained places.

Screws - the main problems and solutions

Therefore, if you do not use kleimers, we suggest you carry out fastening with screws.

Someone may say, in order to fix the lining with screws or self-tapping screws, it must first be drilled. Otherwise, cracking of the board cannot be avoided.

This is not entirely true. Today we will tell you about the method of fastening the lining with screws.

Screws - 0.5 mm matters

Usually, screws with a length of 25 mm and a diameter of 3 mm are used for fastening. At the same time, the cap for such screws has a diameter of 6 mm.

To fasten with such a screw, you really need to pre-drill a hole in the board, otherwise cracking can not be avoided. We suggest that you use screws of a different size.

25 mm long and 2.5 mm in diameter. The cap on this screw has a diameter of 5 mm.

Someone may not believe - well, what is 0.5 mm?

We want to assure you, this small size is very important. If you compare these two screws when you buy, then even 0.5 mm will stand out by eye.

The main advantages of screws

So:

- With these screws you can mount even without drilling, there will be no cracking. Commercially available lining and these screws are very well suited to each other.

- Another important advantage of screws over nails is the possibility of dismantling.

- If necessary, carry out repairs, it is easy to unscrew the screws and remove the coating. Try to pull out the nails without harm to the coating. Unreal.

The right material is not a hindrance to the screw

If you think that the screw cap will prevent the crest of the next board from entering the groove, you are mistaken.

A properly made lining has enough space to accommodate the screw head. If the lining is made correctly and using technology, when connected, there should be a gap inside.

Our advice - when buying, attach two boards to each other as shown in the photo, if there is a gap inside, it is made correctly, if not, incorrectly.

This clearance is simply necessary for linear expansion. Otherwise, the entire coating will deform.

As you can see, there is enough space for the head of the screw.

Our reference - these screws practically do not exist on the construction markets. You can buy them only in large specialized stores.

Mount - quality and reliability

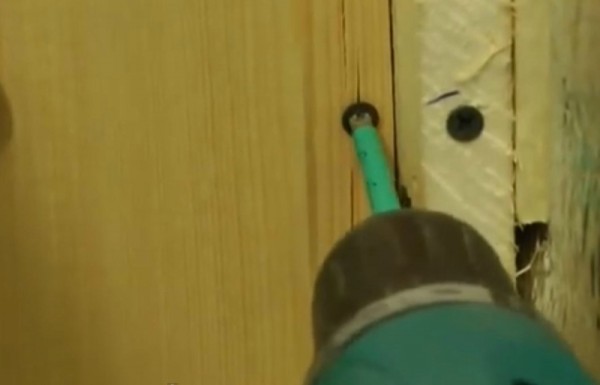

The instructions for this mount are as follows:

- The ph bit No. 1 is inserted into the screwdriver.

- A screw is taken and installed at an angle of 45 degrees in the groove.

- The screwdriver tightens the screw.

Reliable, durable, and even if dismantling is required, it will not be a big hassle to complete it. The crest of the next board is put into the groove of the already installed board and fixed in the same way as in the first case.

Boards can tightly enter one into the groove of the other. If you start knocking them out with a hammer, you can damage the edge.

To do this, you need to use a piece of slat left over from the crate. Bring it to the edge of the new board and striking it with a hammer, achieve a complete connection of the groove and the comb.

Thus, the entire installation is carried out.

Need some advice? - contact

If you are interested in the question - lining the ceiling, the entire video process and a detailed description of all the actions in a wide range are presented on our resource. We have many articles, videos and photo reviews of materials with their subsequent correct installation.

Good luck to you!

Thank! Your advice is very helpful.