Exterior finish of a wooden house: choose the material

Wood, as a material for the construction of low-rise buildings, still occupies a leading position. And this is not surprising, because wood is the cleanest and healthiest material.

No wonder the wooden house is said to “breathe.” The walls of the house, built from coniferous trees, have antiseptic properties.

The content of the article

Reasons to clad wooden houses

The outer cladding of the house is protection:

- from mechanical damage;

- from mold and fungus;

- from the action of sunlight;

- from precipitation and sudden changes in temperature;

- from heat loss;

- from fire;

Facade decoration is also:

- giving the house aesthetic appeal;

- Significant extension of the service life of the bearing walls of your home;

- masking of construction defects;

Options for the external decoration of wooden houses:

- vinyl siding;

- metal siding;

- wooden block house;

- metal block house;

- facing brick;

- brick thermal panels;

- porcelain tile;

- facade painting;

Vinyl siding

Most popular finishing material The wooden facade is vinyl siding.

Panels made of polyvinyl chloride (PVC) can be sheathed not only the facade of the new building, but also to veneer the walls of the old wooden house.

High-quality vinyl siding in appearance is no different from ordinary wooden lining, but it has several advantages over it:

- retains its attractiveness for 20 years or more;

- It tolerates temperature extremes in the range from -50º to + 60ºС;

- 100% moisture resistant;

- easy to clean;

- not subject to mold and rot;

- does not increase the load on the foundation;

In the composition of vinyl siding, polyvinyl chloride is 80%, hence its name.

The remaining 20% are substances that give the siding various characteristics:

- various color schemes;

- opposition to environmental aggression;

- elasticity and resilience;

- durability;

Vinyl siding has the following advantages over a wooden analogue:

- easily tolerates temperature fluctuations;

- does not support combustion;

- provides good ventilation of the facade, taking the condensate out;

- does not crack, does not exfoliate, does not peel;

- service life up to 50 years without changing color and shape;

- you can mount the siding with your own hands;

It is best to mount vinyl siding on a wooden crate. It allows additional facade insulation and create ventilation ducts. And this will protect the facade from mold and decay,

Before installing the crate, the wooden bars must be soaked with an antiseptic. The installation of siding must begin from the bottom.

In order to avoid further warping of siding during installation, you must adhere to such rules:

- When connecting siding, do not pull the panel upward;

- during fastening, do not press the screw or nail head against the panel, leave a gap of about 0.5 mm between the head and the panel, this will allow the siding to expand freely;

- Screws or nails in the middle of the oval mounting hole;

Metal cladding (aluminum and steel) is also used for cladding wooden facades.

Advantages of metal siding over vinyl:

- they resist mechanical damage much better;

- has a wider color gamut;

- fire safety;

- installation can be carried out at any outdoor temperature;

It should be noted that metal siding has a large mass, and this creates an additional burden on the foundation. Metal siding is mainly used for wall cladding of non-residential buildings (warehouses, hangars, workshops).

Decorating wooden walls with a block house

The block house is a wooden board, which on the outside looks like a log. It is widely used for facades of wooden houses.

Advantages of facing the external walls of the house with a block house:

- beautiful appearance;

- simplicity of installation work;

- high heat and sound insulation;

- durability;

- masking defects of the outer wall;

The disadvantages of a wooden block house include:

- higher cost in comparison with siding;

- the need for antiseptic impregnation of wooden parts;

- high fire hazard;

Finishing the exterior of the wooden house with a block house will give the house a look of an original Russian hut. Facing the facade of an old wooden house with a block house will give it a new attractive look.

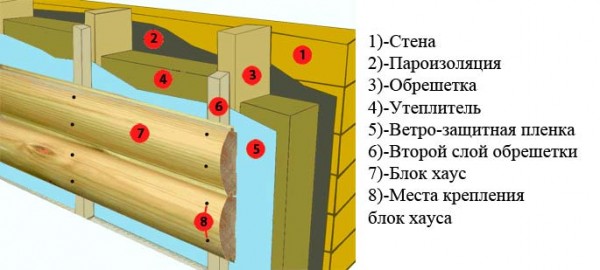

Mount a block house is best on the crate. Between the bars of the crate, you can lay insulation boards and arrange a ventilated facade.

Block house begin to mount from the bottom. Between themselves, the blocks of the block house are connected by a spike-groove method.

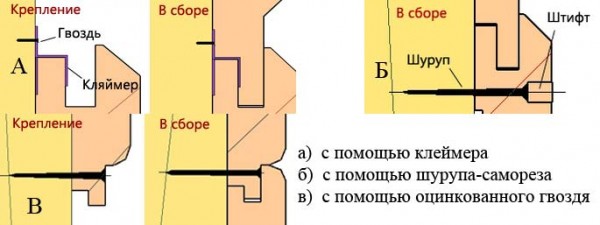

There are three ways to fix a block house to a wall:

- kleimers;

- self-tapping screws;

- galvanized nails;

So:

- in the first version, the kleimer is hooked into the groove, and the other end is attached to the crate with screws;

- in the second case, the block house board is fixed with screws to the crate, while the screw head goes into the body of the board, and then is masked with a wooden pin on the glue;

- in the third case, the block-house board is nailed to the crate as shown in the figure (option B), the next board closes the nail head.

Difficulty in the design of corners can be solved with special corner overlays. Experienced craftsmen make a groove in the log house to the width of the corner and fix it with glue “liquid nails”.

Not so long ago, a metal block house appeared on the construction market.

This material has no drawbacks inherent in a wooden block house (fire hazard, decay, mold). The cost of a metal block house is approximately two times less than a wooden one, although outwardly it is almost no different from it.

Brick cladding

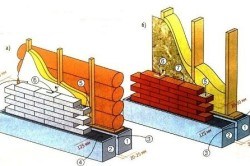

So:

- The existing foundation of the house.

- Additional foundation.

- The gap between the foundations is 20–25 mm.

- Waterproofing.

- Reinforcing mesh.

- Anchor (flexible connections);

- Ventilation gap.

As a finish of wooden walls, facing brick is used.

So:

- For this, a protrusion should be provided in the foundation for the width of the masonry plus the width of the air gap for ventilation of the facade.

- Considering that shrinkage on wooden walls can last up to 3 years, lining should not be carried out earlier than this period.

- Given the seasonal variations in the size of the walls, the cladding is not brought 5 cm to the eaves of the roof.

- Before starting masonry, it is necessary to cover the walls with insulation.

- To connect the facing wall to the supporting wall, galvanized pins will be needed. They should be driven into a tree in such a way that the second end is at least 8 cm long and secured in masonry.

- The pins should be placed 1 for each meter of masonry and in every fourth row.

- Masonry should start from the corners of the house, checking the vertical plumb.

- A clearance of 3 cm should be left between the wall and the lining for ventilation of the load-bearing wall.

- Also, for better air circulation in the first and last row of the masonry, the so-called vents are left. For this, every fourth vertical joint is not filled with a solution.

Cladding of a wooden house with clinker thermal panels

Applying for facade cladding instead of traditional brick clinker panel, you will speed up the work and significantly reduce its cost. The clinker thermal panel was obtained as a result of combining clinker material and a heat-insulating substance.

It turned out a building product with the following characteristics:

- the lowest coefficient of moisture absorption;

- low coefficient of vapor permeability;

- resistance to mechanical stress;

- very high strength;

- resistance to ultraviolet radiation of the sun;

- very high thermal insulation properties;

- very long service life (up to 50 years or more);

- easy to clean;

- environmentally friendly material, harmless to health;

Due to these characteristics, the clinker panel is considered the most suitable material for cladding a wooden facade. Polyurethane or expanded polystyrene is used as insulation in the clinker panel.

Thermal panels are attached to a pre-installed crate made of wooden beams. Since the weight of the panel reaches 19 kg, it should be fastened to three beams with six self-tapping screws.

This achieves the necessary rigidity of the structure.

Begin installation from the bottom and from the corner.

In order to accurately mimic the brickwork at the corner junction, the ends of the panel must be cut off at an angle of 45 ° and the panel needed to be selected according to the texture.

The seams between the panels are sealed with a special grout that will help close the insulation and the caps of the screws. After grouting, the seams cannot be distinguished from real masonry.

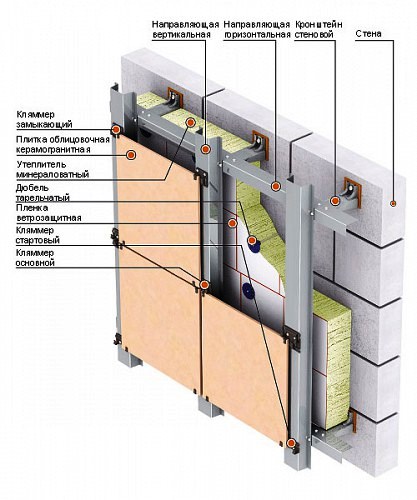

Facing the wooden facade with porcelain stoneware

The facade of a wooden house can be faced with ceramic tiles. This modern finishing material has gained wide popularity due to its characteristics.

The advantages of porcelain stoneware are as follows:

- high strength;

- does not support combustion;

- almost unlimited choice of texture and color;

- various installation methods (for glue, rust fastening or kleimerami);

- frost resistant;

- does not fade in the sun;

The composition of porcelain stoneware includes only natural minerals:

- quartz sand;

- feldspar;

- White clay;

- kaolin;

- various dyes;

The composition of porcelain stoneware suggests that it does not include any chemicals and it is absolutely harmless to health. To fix porcelain stoneware to a wooden wall, it is necessary to mount a metal frame from a special profile.

Insulation is placed in this frame and an air gap is provided for ventilation of the facade. Such a facade is much more expensive than other methods of cladding, but the durability of its operation pays for installation costs.

Painting wooden facades

One of the options for external wooden house finishes is the coloring of the facade.

This coating must meet the following requirements:

- protect load-bearing walls from atmospheric effects (rain, snow, hail, wind, fog);

- sun protection;

- protection of load-bearing walls from temperature extremes;

The market of paints and varnishes presents a wide selection of paints with various characteristics for painting the exterior walls of wooden houses.

Here are some of the most popular brands and their characteristics:

- PVA (polyvinyl acetate) - this water-borne paint is widely used for outdoor applications;

- Acrylic emulsion - well closes walls, is durable, protects from moisture and at the same time maintains vapor permeability;

- Butadiene styrene paint - better protects against moisture, but worse resists the action of ultraviolet rays;

To protect the wooden exterior walls, such paints are also used:

- oil-alkyd;

- oil-acrylate;

- pentaphthalic enamels (PF);

- various varnishes and azure;

In order to qualitatively protect the facade, it is necessary to carry out preparatory work (remove old paint, clean the wall from dirt, priming). Paint the walls with a brush, roller or from a spray gun.

How will the vapor permeability of the timber walls be ensured if you close them with a vapor barrier in the form of clinker thermal panels, which have practically zero vapor permeability?