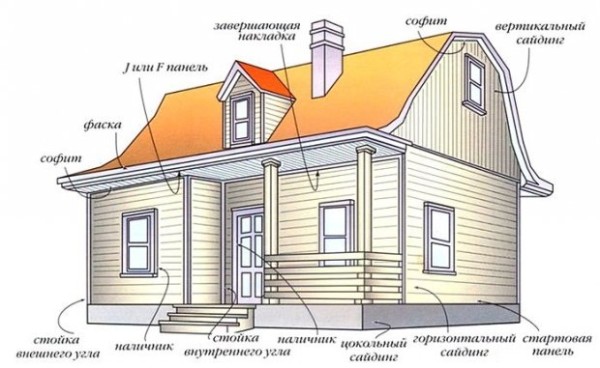

Do-it-yourself wooden home decoration: materials and installation

Wooden structures have been very popular for many centuries. They can be made of any wood.

Finishing a wooden house inside with your own hands plays a big role, since the inside also affects the structure as a whole. This will not only show your imagination, but also save money.

The content of the article

Wooden houses and their characteristics

Wooden house is the most environmentally friendly building. It is built only from high quality prepared material.

The wood undergoes a drying process before use, which can be natural or artificial.

Characteristics:

- As practice has shown, the highest quality material is obtained by natural drying.

- Artificial drying is also popular. The whole process of such work lasts no more than 2 weeks, in contrast to the natural drying method, which takes at least 6 months.

Moisture during artificial drying leaves the wood quickly, which makes it possible to form cracks in the material. - After that, the tree for building a house is treated with means against a variety of insects. There are also substances that help reduce the moisture absorption of this material and increase its resistance to fire.

There are two types of wood, of which quite complex house structures are most often built:

- The rounded log.

- The most popular profiled beam.

- An uncut log (creates the effect of antiquity).

Other features:

- Wooden houses are strong and durable. With proper use of this type of building material, the building can stand for at least 30 years.

- In order to extend the operational period of the building even further, it is necessary to carry out not only external finishing work, but also to finish the internal part of the building, even if interior decoration of an old wooden house is needed and it must be of high quality.

Note. We can say that wood is a practical material. But here everything will depend on the finishing work.

- It is worth considering that such a building material absorbs moisture well and is able to deform under the influence of temperature changes.

- It cracks, shrinks or shrinks. That is why not only the preparation of wood for building a house, but also the protection of a wooden surface plays a big role.

Wood houses are very warm, but they also allow good air masses to pass through. To prevent this from happening during the finishing process, a thermal insulation process is carried out.

Types of finishes in a wooden structure

In the case when outside you can use any finishing materials, but I would like the finish inside the wooden house to preserve the original appearance of the material with its own hands and serve a long service life. All this is possible only in a relatively new building.

What activities need to be done before finishing:

- Initially, caulking of the walls is carried out. It is made using linen thread, and it carefully closes all the cracks of the wooden structure between the logs that could have formed as a result of the laying of wood.

- After this, the surface must be carefully treated with sandpaper.

Note.Such actions should be carried out if the building stood without finishing work for at least 1 month.

- Using sandpaper, the surface of the wood is cleaned. Then you can use paint, varnish, impregnation (tinting).

- Previously, the surface of the tree should be saturated with a primer. This will increase finish strength and quality.

- After that, paint or varnish is applied with a brush.

Tip. For painting a wooden surface, you should not use water-based paint, since the basis for its manufacture is water.

- Cover the surface several times. This will provide quality protection of the surface of the material.

- The price of such interior decorating is very affordable. It is for this reason that insulation work is carried out only outside the house, and inside it is just a decorative design.

- There is another way to preserve the internal appearance of the structure - use a block house and a wooden lining.

The photo shows the interior design with the help of these materials.

Block house and its use

What it is? This is a great environmentally friendly finishing material, which is becoming increasingly popular in the construction industry.

The task of easy installation is solved by a flat surface on one side. And on the other hand, the material has a convex part resembling a rounded beam.

Finishing a wooden house with your own hands using a block house is very practical.

Block house:

- Reliable.

- Practical.

- Durable

- It does not deform under heavy loads.

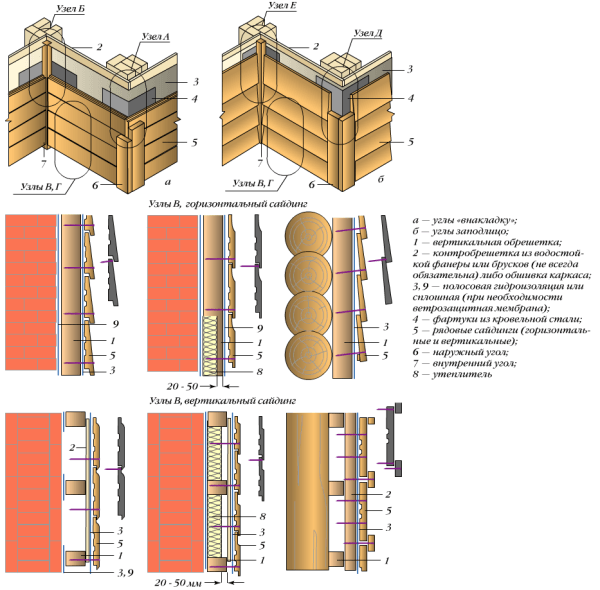

- It can be mounted on the surface, both horizontally and vertically.

- It has an aesthetically attractive appearance.

Tip.

Despite the excellent technical characteristics of this material, its surface should still be reliably protected. To do this, it is varnished.

To install a block house you will need:

- Construction level and screwdriver.

- Wooden boards and bars - for wooden crates.

- Self-tapping screws designed for wood.

- Roulette.

- The material itself and the tools at hand.

Where to begin:

- In order to carry out high-quality internal finishing work using a block house, it is necessary to carry out preparatory work on the surface first.

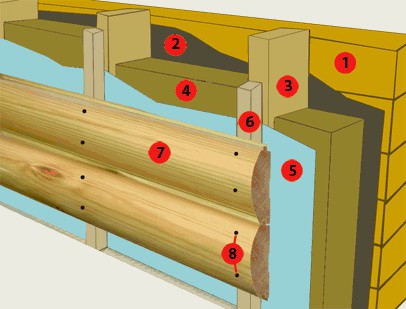

- In their process, a wooden crate is mounted on the wall, which will act as an air cushion, since the material can not come into contact with another. This can cause condensation to form on the inside of the block house and will break down.

Tip. It is recommended that a series of thermal insulation measures be taken.

For this, moisture resistant materials are used:

- Polyurethane foam.

- Styrofoam.

- Layers of solid mineral insulation.

- They are cut to the desired size and inserted into the cells of the crate.

- But here it is worth considering the moment that in this case it is necessary to build another crate on top of the first.

- She will provide an air cushion.

- It is made similarly to the first.

Mounting a block house is quite simple, you will need:

- Construction level and screwdriver.

- Roulette.

- Self-tapping screws.

- Jigsaw or saw.

Stages:

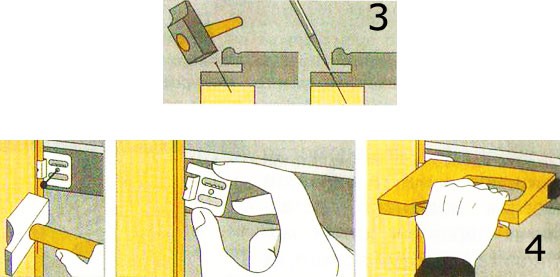

- The installation process depends on which lock the material has. But, the most practical and reliable way to install a block house is to use self-tapping screws.

The first strip of material is level and fixed on the surface. - This strip will be considered a reference point. The required size of the stripes of the block house is cut with a jigsaw, which will help to significantly reduce time costs.

- As soon as all strips of the finishing material are already on the surface, then they are coated with varnish.

Tip.

It is not necessary to use rollers in such works, since they will not be able to paint the surface qualitatively. Better use brushes.

Wooden lining

Wooden lining in its properties is not too different from a block house. It is natural and quite durable.

It also has a long service life of about 15 years. The surface can be made with thread elements or smooth.

Wooden lining has a various size and quite practical.

Tip.

When using such a material, the surface of the lining may be initially coated with varnish, and may also be unprocessed. It is because of this that it is worth covering such a material with varnish or paint.

Mounted lining is quite simple. For this, a crate is preliminarily made on the surface.

For such work you will need:

- Wooden blocks and planks.

- Wood screws.

- Building level.

- Screwdriver.

- Roulette.

- Saw go jigsaw.

During the installation of wooden lining there is also the opportunity to carry out insulation work. They use similar materials (polystyrene, polyurethane and others).

Tip. To decorate the room with a wooden lining, you can not make the second over the first lathing to create an air cushion.

In order to carry out installation, certain materials and tools will be needed:

- Self-tapping screw with decorative hats.

- Screwdriver.

- Level and tape measure.

- Saw or jigsaw.

Finishing Features:

- Since wooden lining is made not only in separate strips, but also in wide plates, it will be quite easy to mount it.

- The first element of decoration is mounted on the crate, you must first check its level. It is attached using self-tapping screws.

- Such actions are done with the rest of the elements.

- If the surface of this material is not processed, then it will be necessary to open it with varnish at the end.

Tip. For such work, it is also recommended to use brushes, not rollers, which are not able to paint the surface in hard to reach places.

If you have questions about installing a wooden lining, it is recommended that you carefully watch the video, which shows such a process completely.

Other materials for interior finishing of wooden structures

The choice of finishing material to a greater extent depends on the "age" of the wooden structure. There are some restrictions on the use of finishing materials.

For example, drywall for new homes should not be used, since within two years the structure gives good shrinkage.

The interior decoration of an old wooden house can be performed:

- Stucco.

- Drywall.

- Siding.

- Plastic.

- Ceramic tiles for interior decoration.

Features:

- Instructions for finishing an old wooden structure do not exist. There are simply certain recommendations that must be observed for high-quality internal work.

- Since a wooden house with a long service life probably has a large number of cracks, due to the natural deformation of wood, then you can not do without insulation and insulation work. Only materials that do not absorb moisture should be used for this.

It is also worth taking care of the quality and density of applying the layers of plaster, if this method of decoration is preferred. This tool is able to fill any holes and crevices, while the surface can have a variety of designs.

A wooden house, without insulation of the external walls, will not be able to provide the necessary thermal insulation of the house, because according to the calculations, the wall thickness, in this case, should be at least 50 cm. Therefore, the house should be insulated with mineral wool, with a density of 30 - 35 kg / m3, thickness, not less than 100 mm. On the inside, the insulation is closed with a vapor barrier, and with an external wind barrier. Facing insulation is best done with a wooden block house. Between the lining and the surface of the insulation it is necessary to arrange a ventilation gap, and install spotlights at the bottom and top of the lining.