Facing of buildings: materials and design

Modern cladding of the exterior walls of buildings is based on the use of materials that can provide not only aesthetics, but also durability of the cladding. In addition, the installation technology of many facade materials allows you to insulate the walls from the outside so as not to take away the useful area of the premises.

There are those that, due to their design features, themselves have heat-insulating properties. In this article, we will talk about how the outer cladding of buildings is made with certain materials, talk about their advantages, and bring to your attention a video.

The content of the article

Frame trim

Facing buildings and constructions in a frame way, today is the most promising type of facade decoration - as it is suitable for low-rise construction, and for high-rise buildings.

Depending on what kind of material is used, fastening methods, types of fasteners, completeness of frame elements differ. But the essence is the same: the cladding is attached to the crate according to the system of ventilated facades.

Sheet materials and front panels

Choose the cladding of buildings based on their purpose and status, architectural complexity of the facade, its area. When it comes to industrial and warehouse buildings, sports facilities, trade pavilions, the first thing that comes to mind is the sheathing with corrugated board.

So:

- To an ignorant person, it may seem that such a facing is monotonous and primitive. About twenty years ago it was, but today the manufacturers of this material offer such an assortment that can satisfy more demanding requests.

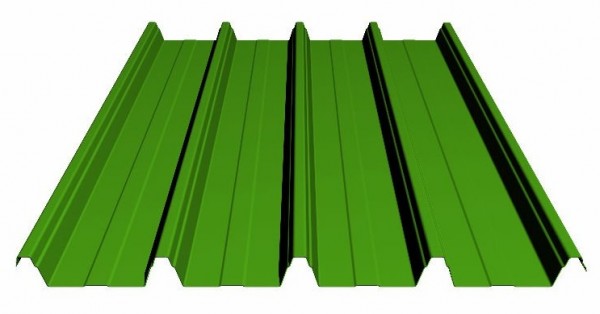

By the way, the owners of private houses also turned their attention to the profiled sheet, and, as you can see, such a facade looks very good. - A variety of reliefs, front finishes, as well as strength characteristics, allow not only to produce facing with a professional sheet, but also use it constructively. And as a proof, we offer a small review with photos and characteristics of the most popular brands.

| Building cladding profiles | Brief description and scope |

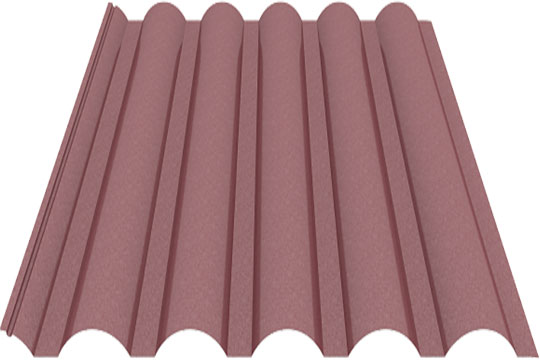

This professional sheet for facing buildings is most often used. Its profile is a smooth wave with a height of 18 mm. In the construction market, it is represented by a variety of colors and options for front finishes.

| |

| These profiled sheets for cladding buildings in their shape resemble a log surface. Beautiful geometry allows you to join the cladding elements into a single whole, as well as combine them with other types of finishes. Moreover, you can arrange the sheet during installation at least horizontally, at least vertically. | |

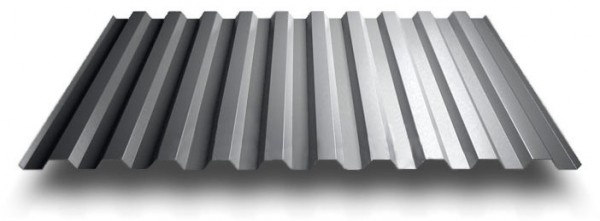

A sheet of S-21 grade has a trapezoidal profile 21 mm high, with a corrugation width of 10 cm. The sharp folds of the trapezoid provide the sheet with good rigidity, which allows it to be used not only as a roofing material and corrugated board for facing buildings, but also constructively. For example, as an independent load-bearing fence or an element of the frame of a light structure.

| |

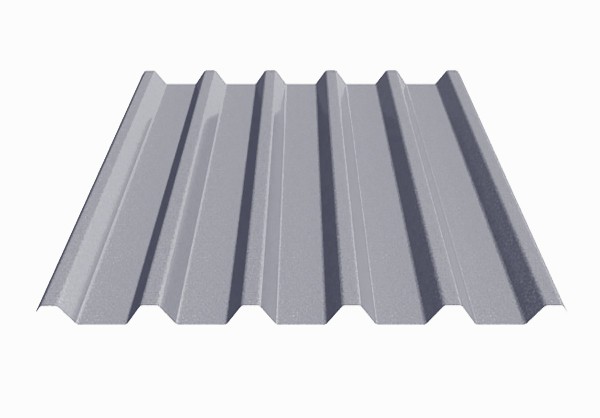

Profiles for facing buildings of the S-44 brand are made of sheet steel with aluminum-zinc and aluminum-silicon coatings, which is reflected in the marking. It is used as a roofing material, for roofs with any inclination.

|

- This is not a complete list of profiled sheets, and if desired, the buyer can always choose the brand that suits him. The metal cladding of buildings is inexpensive, lasts a long time, you just need to decide on the option.

For example, for the decoration of facades of large administrative and office buildings, it is better not to profile, but smooth facing. - For this purpose, use aluminum sheet material, which can be mounted as solid sheets, and serve as the basis for the manufacture of metal cassettes. In fact, it is a multilayer composite consisting of two layers of aluminum with a protective coating and a layer of insulation.

- Such cladding of building structures is not only aesthetic, but also has excellent thermal insulation properties. It allows you to do without installation ventilated facade without insulation, and this significantly reduces the complexity of the work, and, as a result, reduces the cost of finishing.

For buildings with a large facade area, this question is most relevant. Well, if such a facade is also faced with insulation, the building will not be afraid of any frosts. - Speaking about the metal cladding of the facades, one cannot fail to mention such a type of material as aluminum siding. These are long narrow panels with a lock connection, which are also mounted on the frame.

Their coating can be paint, powder or polymer spraying. Moreover, the siding panel can imitate the board - and not only in shape, but also in relief on the front surface.

- Long siding is used only in low-rise construction, and the reason for this is the same laboriousness. The smaller the cladding elements, the more time is required for their installation. But the concept of “siding” includes other types of panels with castle joints: square, rectangular.

- What is this configuration for? Modules with a size of, say, 750 * 950 mm are more convenient when working at high heights than a panel with a length of 3800 meters. This is due, inter alia, to the operation of lifting mechanisms. Therefore, for massive facades use nevertheless, facing of rectangular and square shape.

And those and other options for panels are made not only of metal: in their production uses high-strength plastic (HPL), fiber cement, polymer wood. A huge variety of coatings, colors and reliefs gives inexhaustible opportunities for facade design, and not only.

Natural and composite wood

Wood-polymer panels are excellent for public buildings and homes, as well as for interior decoration, such as corridors and vestibules. Their facial finish, as a rule, imitates various types of wood.

So:

- In the design of facades of massive buildings, any panels decorated with wood are more often combined with other types of finishes. This allows you to get away from the monotony of color, and get a better aesthetic effect. Which, in fact, we see in the example above.

- Wooden cladding of low-rise buildings also refers to frame types of decoration. But the lining board familiar to all, in this case, is not the best option.

The reason is banal: for such a cladding to serve for a long time in street conditions, the board must be primed with an antiseptic, and more than once, but regularly repeated processing during operation.

- For this reason, for facades it is better to use a heat-treated board called planken. Its price, of course, is higher, but the costs are more than offset by a longer service life.

Yes, and a single antiseptic impregnation is quite enough, since the heat-treated wood practically ceases to absorb moisture. - But natural wood is not cheap, its cost is directly proportional to the strength characteristics of the breed. And even, despite the high operational qualities of thermal wood, such a lining is still not eternal.

Therefore, the desire of mankind to create materials whose longevity could approach the service life of the building is quite understandable. Actually, polymer wood appeared.

- Initially, it was created as an option for facing the area around the pool, floors in arbors, open verandas and terraces. That is, where not only ultraviolet, humidity and temperature changes affect the coating, but also abrasive loads.

It turned out that the board, which was so called: “terrace”, copes with such conditions, so why not use it for facing external walls? - A distinctive feature of the terrace board is its hollow structure, necessary for the installation of horizontal flooring. And for the decoration of facades today they also produce a full-body composite board of small thickness, since it does not carry special loads.

It is used both for continuous sheathing, and for design, for example, in the style of fachwerk or Provence.

- When decorating houses in these architectural styles, the internal and external decorative wall strips are made. This refers not to those houses that are built, for example, in a half-timbered style, but to situations when the facade is decorated to this style. This is the finish option presented in our next example.

It is very convenient that the composite board does not need to be treated with impregnations or to perform any kind of finishing. A wood composite is produced, in fact, from production waste.

Strength, moisture resistance and other invaluable qualities, products are obtained due to the polymers used as a binder. In terms of acoustics and thermal insulation properties, composite wood is significantly ahead of many finishing materials.

Facade stone and tile

Among the facing materials, which are also mounted on a system of ventilated facades, there are various large-format plates. This includes porcelain stoneware and ceramic facade tiles; natural rocks for facing the building, as well as artificial stone, which is made in the form of plates using granite or marble chips in the production.

So:

- Take at least a facade tile called Ceramics Terracota. It is made from a certain type of clay, from which the tile got its name. It most often has a natural color, and its beauty is emphasized by applying glaze to the surface of products.

- There are three sizes of terracotta tiles in a rectangular version: 600 * 1200 mm; 500 * 1000 mm; 300 * 900 mm and 300 * 600 mm - and two types of square tiles: 600 * 600 mm and 500 * 500 mm.

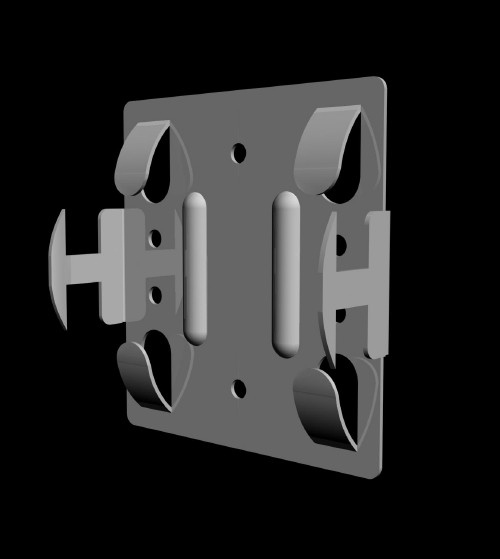

- The thickness of the products is constant, 12 mm. The larger the format, the greater the weight of the product - one tile 600 * 1200 mm weighs 28 kg. Naturally, no glue can stand such a mass. Therefore, such heavy types of cladding of a building are mounted only on the frame.

The tiles are held by special fasteners - kleimers, which are firmly fixed with screws on the supporting profiles of the frame.Otherwise, the installation of a ventilation facade with ceramic cladding is carried out similarly to systems with other types of panels - and the manufacturer's instructions will always help to do the work yourself.