Insulation of the walls of a wooden house from the inside: technology

Wall insulation in a wooden house from the inside, of course, must be done. After all, penetrating moisture contributes to the destruction of wood and not only does the building become unusable, but as a result, the room will be damp.

How to insulate the walls in a wooden house from the inside, we will consider today. Also on the video in this article and photo you can see the whole process of doing the work visually.

The content of the article

Preparation for the main types of work

Insulation of the walls of a wooden house from the inside is done according to certain rules and in compliance with the desired sequence. The quality of the work performed will depend on this.

Before starting work, it is necessary to take measurements and calculate the material. And also, it is necessary to make calculations for the further selection of insulation material, taking into account, inter alia, its properties (seeMaterial for wall insulation inside: characteristics) Do not forget that in such works, membranes are used (vapor insulating and waterproofing).

In the calculations, it is established:

- Dew point output. This is one of the most important points in this type of work. The explanation is very simple - how much, as a result, it will be humid in the room, it directly depends on this, even in cases of high-quality material, and well-executed work. It takes into account the location of the membranes, and their properties (they may differ from different manufacturers), and of course the properties of the insulation (density, resistance to wetting).

- The calculation of the total area of the room, given that it will decrease. It may not be a comparison (an increase in slopes, but if there is a furnace, the safe distance will change, which is unacceptable between the wall and the furnace, for fire safety).

Important: The need for work to establish the dew point is not discussed. This is an inseparable part, providing, ultimately, the meaning of the whole work. You need to understand - the humidity of the room depends on the location of the dew point, and humidity is rotting, smell, in the end - premature decay.

Rules for the performance of insulation

Warming the walls from the inside with your own hands of a wooden house is done in the presence of quality materials. Preference should be given to trusted brands, on Chinese material you can save a little, but significantly lose in characteristics.

What will be needed for work

Insulation of wooden walls from the inside is done by heaters, there are quite a lot of them. But one must proceed from the structure itself and what you want to get in the end.

By definition, the insulation must meet the requirements of:

- Have low thermal conductivity;

- Meet fire safety requirements;

- Comply with environmental and chemical safety standards.

Attention: When choosing a heater, the density and heat transmission qualities are determined, taking into account the place of its application, weather and temperature features, as well as the state of the building itself.

- The material used must not support combustion, emit hazardous compounds into the air, and contain hazardous chemical elements. For internal work, the material is selected with particular care, environmentally friendly and safe.This is important, because - in a confined space, with constant contact, even a seemingly not significant deviation from the norm can be dangerous, and for both people and pets.

Types and types of insulation materials

Determining which method to use, you first need to decide which material will be used. This is interconnected, since the method and method depends on the type of material.

Of the possible methods used indoors - use:

| Mineral wool | It happens in plates and rolled, various density. In fact, the difference in application is almost nonexistent. Any of these materials implies a closed type of application, that is, after installation, it must be closed (finishing material in the form of - plates, sheets, boards and battens). Such a heater does not burn, is not toxic, has low thermal conductivity. But he is afraid of moisture, which means that it is necessary to use insulating membranes (insulating films). |

| Polyfoam plates (expanded polystyrene) | It is not recommended to use inside the living room, due to possible toxic release (hydrogen cyanide, styrenes, etc.). It is possible to use extruded polystyrene foam, but such a material is also designed for installation with subsequent closing. |

| Glass wool | Relatively not expensive material, a little more thermal conductivity than mineral wool (you need a thicker layer). There is a special option, for internal work, and with the mandatory use of films, for shelter. At work, it is also necessary to observe safety measures (protect the respiratory tract from small particles, use protective equipment). After laying, it is necessary to close. |

| Isoplet | This material is environmentally friendly, it consists of flax fibers and wood shavings. Represents pressed plates 12-25 mm thick. since this is a sufficiently rigid material, the need for a solid fence (crate) is no longer needed. Environmentally friendly, suitable for use indoors. The disadvantage is the higher thermal conductivity, and the cost, however, is higher than that of alternative materials. |

| Polyurethane foam | It is used using special equipment, it does not burn itself, but at high temperatures, toxic substances are released.

|

Now let's figure out how to insulate wooden walls from the inside from a practical point of view.

Sealing gaps, preparing the surface for insulation

Since the construction of the building, during its operation, the tree dries up, the house "shrinks", the constant movement of materials. As a result, cracks and cracks form, which must be repaired to stop the loss of heat.

- Joints between logs (or timber) - caulk. This is done, with accessible material, or with the same thing that was done earlier (tow, jute, sealant). As a result, heat loss must be stopped.

Attention: Do not hope that the house is relatively not old (or new), cracks can occur throughout the "life" of the building. It is necessary to check the condition of the wall (plywood, “lining”, will not solve the problem with cracks).

- Wood treatment with a composition that prevents burning. We must not forget about fire safety. To prevent possible fire, special formulations exist. These are liquids, possibly combining both an antifungal and fire-fighting composition. They process it with both a wooden wall and the construction of the fence.Such a composition is selected, taking into account the oldness of the treated surface.

- It is possible to cover the timber with liquid in any available way. For example - paint with a brush or roller (seePaint rollers: consider in detail) If possible, it is possible and a spray for paints. After that, it is necessary to dry the processed bars, laying them out exactly, on the “spans”, pressing them on top with something heavy (boards, other building materials).

Insulation ventilation

An important point, when warming, is ventilation. Given that all the slots are closed, the free circulation of air masses ceases, which ultimately leads to "perspiration".

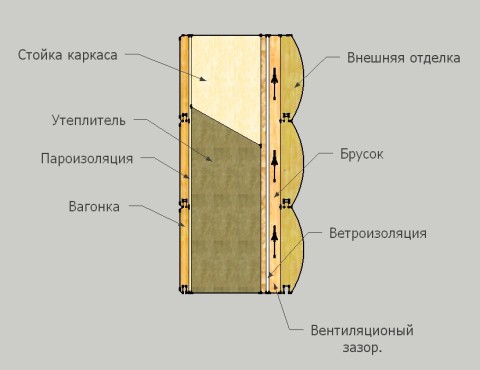

- You can avoid this in a tricky way by arranging a ventilation “duct” between the wall and the steam with an insulating film. This is done this way - not the wall, thin slats (2-2.5 mm) are attached, then, on them, a pair of insulation is stretched. Thus, a "vent" for air is formed. If the house is built up their "round" - the slats are not needed.

Caution: Thermal insulation can be considered good, subject to ventilation. This, an important element is necessary, because - other options are excluded by sealing cracks and cracks.

- Membrane steam isolated. It is mandatory to install, when using materials that easily absorb moisture (glass wool, basalt). Mounted with a stapler, on, slats nailed to the wall. The film is attached to a whip of 10 cm. The joints are glued with double-sided tape. In the event that the material is water-repellent (extruded polystyrene foam), a membrane is not required.

Crate

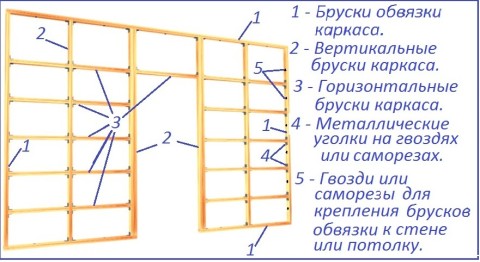

Insulation of the wooden wall from the inside is done on the crate. It must be fixed rigidly and withstand the weight of the insulation.

Attention: The beam must be treated with antiseptics before installation, this will significantly extend its service life.

So:

- It is mounted vertically, the distance between the bars is done depending on the insulation material. For example - soft material (glass wool, mineral wool) - the distance is made smaller so that the insulation "sits" tightly, but at the same time, does not crumple during installation. Such material as (from boards, extruded polystyrene foam) does not require a decrease in the gap, but it is laid without gaps.

- The crate itself is made from a bar of 50x50 mm.

Attention: In the event that a ventilation rail has been ramped up, the beam is mounted directly on them, ensuring the preservation of the ventilation space.

- A wooden beam, in fact, also plays the role of insulation, which is why it is most often used, however, when planning, in the future, finishing using drywall (seeHow to plasterboard walls correctly), it is permissible to fix the steel profile (on suspensions). In this case, the insulation material is laid under the profile.

- Insulating the floor and ceiling, the principle remains the same, but when planning such work, you need an insulation film, put out an overlap of 10-15 cm (on the floor and ceiling), so that in the future, connect to the film of the ceiling and floor. On the floor, the crate plays the role of a lag, on which, then, the floor itself is attached, so the thickness of the beam, and the step, is largely determined by this.

Laying insulation material

During installation, it follows the rules for the placement of material. It must not be deformed, otherwise the insulation loses its properties.

- With a maintained distance, between the boards, the insulation "becomes" tight, usually more strengthening is not required. But at work, it is much more convenient when everything is held securely. Especially if the work is carried out with a ceiling. It is recommended to further strengthen the material in the middle, by one cut itself (special, with a large hat).

- In cases where polystyrene is used, all remaining gaps are compensated with mounting foam (preferably on a wet surface).

- The rolled version of the insulation is fixed at the top, then, gradually going down to the bottom, it is attached directly to the wall, at a distance of 1 meter. One-piece material is used, all “cut-offs" are put into refinement (termination, preferences).

Insulation

After the installation of the insulation is completed, a shelter with a vapor barrier film is made:

Attention: This is done on all types of insulation, with the exception of polystyrene.

- Very carefully, you should study the purchased insulation. It works in one direction (there steam and moisture passes, back - no). Different manufacturers have different side markings (red strip, rough side, mesh screening). It is important not to confuse. To do this, you need to understand the principle of operation, or remember - it is necessary, in this case, to ensure that the moisture from the insulation enters the room, then it is equalized with the humidity of the room, thereby eliminating the temperature drop, which means the appearance of condensate.

- It is attached, similarly to the one on the wall, with a stapler, from bottom to top, 10 cm overlap. The joints are necessarily glued with double-sided tape.

Important: Do not allow contact with the insulation, so sometimes you need to correct it so that it does not protrude beyond the edges of the crate and does not touch the film.

This design is suitable for almost any finishing materials. Whether it is drywall, or panels, “wall paneling” (seeInterior decoration with clapboard wooden house: only natural material), or just plywood sheets. The difference is not big, in the location of the crate (horizontally or vertically). This point needs to be considered when planning.

findings

Work such as this is carried out, as an exception, in cases where there is no other option:

- The most acceptable is a comprehensive insulation, which includes both the floor and the ceiling, as well as the attic and roof. In this case, the result will be tangible.

- It is not disputable that before starting work, it is necessary to carry out diagnostics in order to identify possible defects, as well as in order to determine the choice of materials, taking into account weather conditions, identifying the dew point.

- The selected insulation must comply with fire safety standards, be environmentally friendly.

- All types of insulation material that can absorb moisture are used with insulating films.

- Using wood as a building material in the work, processing with a composition that prevents fire and rotting is mandatory.

- Insulating films, before use, are carefully studied so as not to confuse the parties.

- When working with glass wool, it is necessary to take safety measures - use a protective mask.

Now you know how to insulate the walls of a wooden house from the inside and the instruction will help in this matter. The most important thing is not in a hurry and perform all areas of work efficiently. This will be the key to the longevity of the room and a comfortable stay in it.