Material for wall insulation inside: characteristics

All finishing and building materials produced by modern manufacturers are aimed at saving. Many may be surprised by this conclusion, especially if we recall the price of them.

Let's try to explain our point of view: the topic of our article is material for wall insulation inside the house, and they are designed to save heat in the room. We will talk today about the quality of the insulation, heat loss directly depends on how to choose it correctly.

The content of the article

What do we expect from a heater

The thermal conductivity of walls made of different materials can vary significantly, which is why it is so important to choose the right insulation (see. Let's consider in detail which insulation is better for walls), for example, walls made of light warm material do not need a radical approach, unlike wood, which tends to freeze in winter.

The selection factor is especially important for owners of old buildings, houses that, over time, lose their energy-saving properties, can also be redone so that it will be like new. So how to choose a heater?

First of all, it is necessary to understand what basic criteria should be present in its qualitative characteristics:

- The level of thermal insulation. The choice of insulation is not a situation to which the saying applies that you can’t spoil the porridge with butter. If your walls are built of thick ceramic bricks, then the use of strong heaters does not make sense, you just spend extra money on them, and energy saving will remain at the same level.

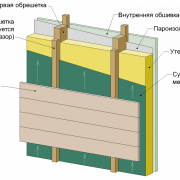

- Vapor permeability. The factor is especially important for wooden houses, or for old buildings. The fact is that it is on them that condensate most often accumulates, which over time can develop into a fungus or mold. The insulation in this situation should have a high degree of vapor transmission.

- Safety. Since we are talking about materials for insulating walls from the inside of the house, it is very important that they are completely safe. This applies to fire safety, the insulation must not support combustion, and environmental friendliness, it is impossible that the composition of the insulation includes harmful chemical compounds that can harm human health.

- Heat capacity. Often, the quality of the insulation directly depends on its thickness, and it is very bad, every centimeter is important inside the house, and when using such materials, you can lose up to 15 centimeters from each wall, and when you take into account all four walls, the loss in area becomes very noticeable .

These are the main selection criteria, and in addition, ease of installation can also be attributed, especially if the repair is done by yourself, and you do not have a huge set of tools. Looking a little ahead, we note that far from all the heaters you can install yourself.

Important! The most important thing when choosing a heater is an accurate calculation of the heat capacity, it will depend on it the final result, and in some cases, such a calculation helps to significantly save material costs, which is also important.

So, we figured out the basic criteria, but what material has all of them? In varying degrees, any, but in different proportions, so we will further examine in more detail the main and most popular types of insulation that can be used inside the house.

Soft cotton-based insulation

Which of us does not remember the notorious glass wool, after touching which, you could get a serious burn.Modern cotton wool is not the same, and you can even sleep on it without getting any unpleasant sensations. all the manufacturers needed was to exclude ground glass from its composition, and it turned out to be one of the most popular materials for wall insulation today.

The main advantages of this material are two factors:

- A light weight. Vata does not create any load on walls and partitions, and this is especially important for houses built of light materials, or on a weak foundation, where every kilogram is important.

- Easy to install. In some cases, it is generally unnecessary to attach cotton to the base, it is simply fixed between the guides of the battens.

An interesting fact is that the second point often becomes a disadvantage, since with constant contact with moisture, cotton wool accumulates it in itself and becomes heavier and just falls into lumps. Something similar happens with cheap synthpone jackets, which, after washing, dump the entire insulation into the base.

If your walls do not have contact with water, then you can not worry about this, but in some rooms in the house, such contact simply cannot be avoided, so it is advisable to additionally fasten the material to the wall with glue or special plastic dowels with wide caps.

Important! Choose mineral wool only from reliable and trusted manufacturers, as some unscrupulous "business people" use formaldehyde in it to reduce the cost of production, which, if accumulated, can cause significant harm to health. The price of such dangerous cotton wool may be lower, but is it worth the health spent? Surely, the answer to this question is unequivocal.

Basalt wool

Many people wonder what material to insulate the walls of the bath, and so, basalt wool is best suited for these purposes. Unlike mineral wool (see How is insulation of walls outside with mineral wool), it includes natural volcanic basalt, which, in addition to heat-conducting qualities, has the highest temperature resistance.

Such cotton wool can insulate not only walls, but also the stove, and even the chimney. It is completely not susceptible to high temperature and open flame, and when heated it does not emit harmful substances, which is also important for a bath and sauna.

Basalt wool is more expensive than mineral wool, but its quality characteristics are much higher, therefore, if your repair budget can afford it, the choice does not even arise. Often, its qualities may seem superfluous, but it is worth noting that basalt is much more resistant to contact with water, and in addition to the fact that it does not support combustion on its own, in the event of a fire, it can even prevent the spread of fire through walls and partitions.

As you can see, the rolled material for wall insulation is very convenient and practical, but you should not stop there, not appreciating all the advantages of other heaters, which will be discussed later.

Styrene-based thermal insulation

The word styrene scares off many people, it directly blows from chemical formulas and harmful production. But this is a common misconception that came to us from the distant past.

We all remember polystyrene (see How is warming the walls with foam yourself), which was previously used to transport fragile items. Today it is also used as a heater, and a very good heater, which retains heat perfectly, and at the same time does not deform with time.

There is an opinion that polystyrene is harmful to health, and this is also a misconception, chemical reagents are used in its production, but they are completely safe.To mention at least the fact that in the walls insulated with this material, rodents are very often wound up, which, as you know, are very picky when choosing building materials for their homes.

The presence of rodents, of course, can be attributed to the shortcomings of this insulation, but it is very easy to get rid of them even at the stage of construction or wall decoration, just treat the surface with special fluids, and the mice will bypass your house.

It is also believed that polystyrene is a hazardous material, since it is highly flammable and emits harmful caustic substances during combustion, which in case of danger can become a significant barrier to evacuation.

But here it should be noted that this is relevant only for cheap materials, and high-quality foam has in its composition special flame retardants that make it immune to high temperatures. And even if there is an open flame, it simply loses its shape, but does not ignite.

Penoplex

One of the modern varieties of styrene insulation, which differs from polystyrene in higher density and the ability to maintain shape under the most intense loads. When choosing which material to use to insulate a brick wall, it is best to give preference to this material, since with the same heat conductivity with foam, it will be much thinner, but stronger.

This effect is achieved due to deep pressing in production, as a result of which, much more raw material is spent per cubic meter. The result is density, and the ability to keep warm even with severe frosts outside.

The hardness and resistance of the foam to stress and mechanical stresses make it possible to use it not only as insulation for walls, but it is also used in the roof space, and even for sealing floors.

Moreover, in some cases, penoplex is used as a substrate for paving, in those situations where you need to get rid of the constantly formed ice on the surface.

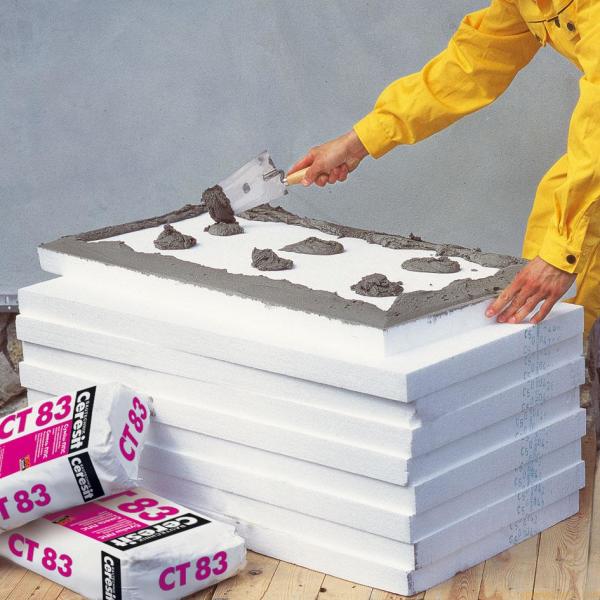

With the fastening of this insulation, too, problems should not arise, since it is fixed on glue or on the same dowels as mineral wool. And besides this, each penoplex panel is equipped with grooves and ridges that improve the adhesion of the segments to each other and eliminate cold bridges at the joints.

Advice! Despite the fact that the plates are tightly interconnected, it will not be superfluous to go through all the joints with penoizol, for more reliable insulation.

Polyurethane foam

The more familiar name for this truly unique insulation is penoizol, and most of us are used to perceiving it as an insulator of cracks, which is used when installing doors or windows. Such foam is sold in cylinders, and if you imagine how many they will need to cover an entire wall, you can be horrified by the final cost. But with polyurethane foam for insulation, things are somewhat different.

In this case, it is produced in the form of two separate substances, which, when mixed, form the same foam. For spraying, special expensive equipment is used, so you will not be able to produce independent insulation. Of course, you can buy a spray gun for foam, but this is unlikely to be cost-effective.

In order to better understand the whole process, we suggest watching the video in this article. This is not an instruction for work, but rather just a video clip that will help to understand that without experience and certain knowledge, it’s better not to undertake this business, but to entrust it to specialists who are familiar with all the subtleties.

If you are looking for non-combustible materials for wall insulation, then foam is exactly what you need. Upon contact with an open flame, it simply loses its shape, but at the same time it maintains combustion and does not emit harmful toxins.

An interesting fact is that penoizol can be used not only as a material for wall insulation from the inside, but also outside the house. Moreover, there is a technology for pumping insulation into already constructed walls, in which there are voids. This practically does not exert pressure on the foundation, and the walls become not only warmer, but also stronger, since the foam reliably fastens the partitions and makes them a real monolith.

Drawing a conclusion from all of the above, it can be noted that polyurethane foam is one of the most high-quality and reliable heaters, which has unique qualities that no one else has:

- A light weight. It can be used without fear for warming wooden and plasterboard partitions.

- Safety. After hardening, the foam does not emit harmful substances.

- Reliability. The absence of joints completely eliminates the formation of cold bridges.

- Durability. The foam is not afraid of temperature changes and high humidity.

Among the shortcomings of this material, one can distinguish a relatively high cost, and the impossibility of self-application, but given the positive aspects, one can no longer pay attention to these nuances. So, we told you about the best materials for insulating walls, and which one to choose, it is up to you to decide, the most important thing is to clearly follow the rules and recommendations for choosing, as well as calculate in detail the heat capacity of the walls and insulation.