Facade plaster coat: features of use

Fur coat plaster is found quite often. Today we will familiarize ourselves with this material in detail, find out its features and rules for applying to the surface. Also in the video in this article you can clearly see the whole process of this work and in the photo certain moments.

The content of the article

Finishing a house “under a fur coat”: advantages and disadvantages

The facade plaster coat has its positive and negative sides.

Before buying material, you should familiarize yourself with them:

| Advantages | Such plaster has several advantages:

|

| disadvantages | For all its advantages, a “fur coat” has a number of disadvantages:

|

Correct application

Application instructions are not complicated. Here you just need to be careful and properly prepare the solution.

Facade preparation

Using this technology, you can cover any surface: brick, concrete and even wood. If it is required to finish wooden surfaces, a slightly different technology is used: before applying the “fur coat”, the surface is treated with special primer.

The volume of plastering depends on the technical condition of the surface:

- If the wall has irregularities of not more than 2 cm, then special preparatory work, except for cleaning the surface, is not necessary;

- With irregularities of more than 2 cm, the wall requires leveling, using rough plaster with sand-cement mortar (see Cement-sand plaster: material features);

- If the surface is old and there are traces of destruction, then these chips and cracks should be removed. If the surface is strong enough, then for better adhesion to the "coat" notches are made on it;

- The same technique can be used if the wall is lined with a facing brick having a glossy surface.

Plaster of the building "under a fur coat"

For this, mixtures having various components can be used. The main thing is that such a mixture is intended for outdoor use. In extreme cases, you can cook it yourself.

Making the mixture

For plastering surfaces “under a fur coat” a sand-cement mixture is used:

- As a rule, for the preparation of the solution, river sand and cement of the M300 or M400 brand are used, in a ratio of 3: 1.

- First, the components are mixed dry, and then diluted with water to the desired consistency: normal is considered to be a density similar to the density of mashed potatoes.

Attention; To select the desired texture, you need to prepare a little solution and try on a small area. The texture can be changed by changing the density of the solution: the thicker the solution, the more pronounced texture.

You can make the facade more interesting and attractive:

- If you add a suitable dye to the finished solution. The painted “fur coat” does not fade in the sun and retains its color for a long time;

- Play with the texture of "fur coat", if you add enamel paint and putty to the finished composition, in a ratio of 50/50;

- Add to the solution pieces of white, multi-colored glass or marble chips, etc.

Fur coat plaster facade can be done with your own hands. It is also produced in packaged factories and there are also packaging options by firms.

| Pre-mixed dry mixes | Basically, dry mixes are made using cement, as the main binder, and can be produced in both white and color. Moreover, they are much cheaper than ready-mixed plasters. The method of preparation is as follows: the plaster is poured into the container and water is added. After that, the mixture is mixed using a construction mixer or an electric drill with a nozzle. It is very important that the mixture is kneaded as much as required, and that this mixture is consumed in one go, covering the required area. |

| Ready-made mixes for “fur coats” | Ready mixes are mixes mixed at the manufacturing plant to the desired consistency. Ready mixes are made on the basis of acrylic, which gives them high elasticity. It has low vapor permeability, but allows you to get a surface that is resistant to cracking. |

The technology of applying a "fur coat" on the facade

Buildings have been finished in this way for a long time, so there are a lot of technologies developed for this method.

Preparatory stage

If the surface is sufficiently smooth, then the preparation of such a surface is as follows:

- Cleaning the surface of dirt, dust and small lumps of mortar. To do this, you can successfully apply a metal brush;

- If the building is of considerable age, then it will not hurt to treat it with an antiseptic;

- Obligatory coating of the surface with a deeply penetrating primer, which will improve the adhesion of the coat to the surface.

| Rough plaster

| Before facade decoration, even a flat surface is recommended to be plastered using the rough surface method.

|

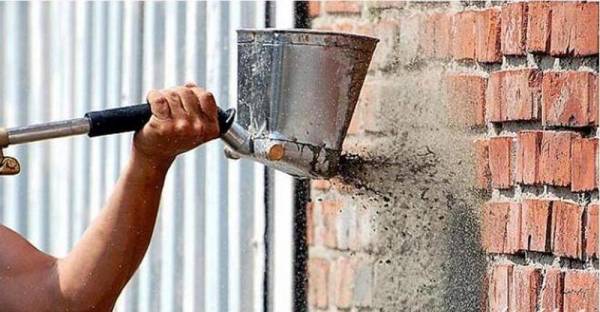

| Drawing a "fur coat" on the facade with a broom | The easiest way that does not require certain skills.

|

| Getting a "fur coat" through the net | To do this, you need a fine-mesh mesh of metal, which is applied to the wall, and a plaster layer is applied on top with a trowel.

|

| The use of a special roller | Using a special roller, you can structure the surface so that it looks like a "fur coat". The technology of obtaining such a surface is that a thin layer of plaster is applied to the surface of the wall, after which they pass along it with a roller. After this, a certain structure of the plaster layer remains. The technology is not laborious, but also requires professionalism. |

Technical means of obtaining a "fur coat"

It is not surprising that at one time technologies were developed to obtain such a cladding using special devices, since at one time it was very popular (fur coat).

- Such a surface can be obtained using a compressor. It makes it possible to process, in a short period of time, large areas, without violating the main drawing.

- The machine for applying a "fur coat". Plaster is applied to the surface using a rotating drum. Using such a machine significantly increases labor productivity, but the proportion of manual labor is much higher than when using a compressor.

When applying plaster to the building facade, it should be remembered that the wall should be treated with the same solution in one go.

Color painting of the facade of the house "under the fur coat"

To make the “coat” colored (multi-colored), dye is added to the stucco mortar at the stage of preparation.

- Its amount should be such that the desired shade with good saturation is obtained.

- The colored “fur coat” practically does not fade, which makes it possible to exploit such a surface for a long time without repainting.

Attention: With one batch, the color will always be the same. But when repeated, there may be a different shade. After all, not just the dye plays a role here, but its proportion and volume of sand.

Spray painting

This may be the most suitable and effective way to paint a coat, moreover, it is the most economical. Under the action of high pressure, the paint breaks up into tiny splashes, which evenly cover the entire surface.

- Before applying the paint, the surface of the “coat” should be cleaned and covered with a primer (see Facade primer - its types and application).

- Finishing the facades of the building under a "fur coat" is a fairly affordable and relatively cheap way to give the building a decorative look. The technology is not very complicated, which makes it possible to master it in a short time, and having shown imagination and adding dyes or other components to the stucco mortar, you can give the building an exclusive appearance.

Attention: If you need to repaint the finished surface, then this is not so simple. Since the surface has a certain pattern formed by adhering drops of the solution, it is hardly possible to paint it in the traditional way: we mean the use of a brush or roller. With a roller, you don’t even have to try, and with a brush you can, but it will take a lot of paint and time.

Tips for applying a "coat" with your own hands

Despite its apparent simplicity, it is necessary to apply a "fur coat" to the surface correctly. Only in this case, the surface will last a long time and will protect the facade of the building for decades.

In order for the “fur coat” to turn out solid and reliable, some recommendations should be adhered to:

- Apply this plaster under certain weather conditions. The ambient temperature should be between + 5 ° C - + 27 ° C. It is desirable to protect the surface from direct sunlight. It is best to carry out such work on a cloudy day, but not on a rainy day;

- It is desirable to go through all the layers in one go, allowing each layer to dry out;

- The surface must be primed;

- To obtain different colors, it is recommended to add such dyes to the solution: red iron ore, manganese powder, white asbestos, crushed white marble, crushed cobalt glass, coal powder;

- Do not use thick solutions. Consistency should be fluid and, at the same time, not float on the wall;

- To get an acceptable texture, it is better to use a metal mesh or stick with a broom.

Plaster facade coat is not expensive, but the service life is long. Also, you will not need to spend money on maintenance. So having done all the work with your own hands, you will get a quality surface at a low price.