Lime plaster: composition and use cases

Cement-lime stucco mixture is widely used in construction. This composition has many positive qualities and is easy to apply and apply.

Today we will tell you how to make lime plaster with your own hands. Indeed, with large volumes of work, it is worth doing it with your own hands, then the price of finishing will not be large. Also on the video in this article you can see a lot of useful and necessary information.

The content of the article

Properties and indicators of lime plaster

There are various types of plaster mortars, among them the lime mixture is not the last in popularity.

This solution was widely used due to its positive characteristics:

- The presence of high thermal insulation properties;

- Resistance to fire;

- Plasticwhich provides convenience and ease of application;

- Ability to withstand mechanical stress: does not crack when driving nails, holding them tightly inside;

- The content of alkaline elements prevents the appearance of fungal infections, mold;

- Protects wooden surfaces from the effects of insects, rodents.

- Repair of lime plaster is quite simple and you will not lose much time.

The technology of preparation of lime mortar

The basis of the lime mixture is a correctly selected ratio between hydrated lime and river sand, where 2 to 5 parts of sand can be taken per part of lime. The volume of sand depends on the degree of fat content of lime.

When preparing a solution, pay attention to the following things:

- Strong adherence of the mixture to the oar indicates the need to add sand. This will help reduce the fat content of the solution.

- The mass does not lie well on the surface, does not hold on to it - you need to add more lime.

The process of obtaining a lime mixture consists of performing sequential steps (see We prepare ourselves a mortar for lime plaster).

To extinguish lime lime, let's look at how to extinguish lime for plaster:

- Pour dry lime into a non-plastic container;

- Pour warm water so that completely lumps disappear;

- Close the container with a lid to prevent spillage of lime after the onset of a chemical reaction with water;

- As soon as the boiling process stops, drain the white liquid using gauze;

Attention: Leave the resulting lime mixture for a day to thicken.

- Sift sand through the grate, a sieve with a mesh size of not more than 5x5 mm.

- Add a little sand and water to the container with the lime mixture, mix well to get a homogeneous mass without lumps.

- Gradually introduce the remaining sand, adding water.

- Ready mix for plaster should have normal fat content and consistency of medium viscosity.

Caution: The mortar for lime-based plasters has a slow setting time, so it will be suitable for work for two and a half days after mixing.

Types of lime solutions

Lime is a material that combines perfectly with other components, such as gypsum, cement, clay.It is this ability to combine that allows you to create different types of stucco mortars based on lime with new improved characteristics.

Consider the varieties of mixtures and methods for their preparation.

Gypsum-gypsum mortar

Its characteristic features are the strength of the applied layer, the quick hardening process, compared to just a calcareous mixture.

- It is used for interior decoration with a normal level of humidity. Gypsum, as an additive, influences the process, accelerating it, since after 5 minutes the solution sets, and after half an hour it completely hardens. As for outdoor work, it is practically not used.

Attention: therefore, this type of solution is prepared in a small amount, up to 5 liters, which allows you to maintain the characteristics and use the entire mixture before it hardens.

Not recommended for work for beginners who do not have building experience. Gypsum on lime plaster is added in small portions and mixed thoroughly. It should get a completely homogeneous mass.

Cooking process:

- Prepare a regular lime mixture.

- Remove approximately 3 liters of solution from the container.

- Pour gypsum, add water, mix well.

- Return the seized solution to its place and mix thoroughly for 3 minutes. If necessary, add an additional portion of water.

- Immediately use the ready-made solution for 5 minutes.

The ratio of the components is as follows: for 1 part gypsum, take 4 parts of the lime mixture. A small nuance: the liquid mixture is easier to apply to the surface, since the setting process is slower, but the strength of the finished layer suffers.

Lime and clay solution

The following components are taken for it: clay mixture, lime dough and sand in a ratio of 1: 0.5: 3–6. A clay mixture is prepared in a similar way: water is added to the clay, kneaded, left for several days. After the allotted time, water is drained, obtaining a plastic pasty mixture at the outlet.

Manufacturing technology:

- Prepare a container in which then mix two binders: lime and clay.

- Introduce sand and water in small portions, constantly rubbing the mixture with an oar.

- Pay attention to the state of the solution: if it sticks strongly to the oar, then clay with increased fat content - you need to add more sand. On the contrary, when the solution does not stick to the oar, reduce the amount of sand.

- The main advantages for which the clay mixture is valued are the low cost of raw materials and the environmental cleanliness of the material.

Clay solution in its pure form has low strength of finished plaster surfaces, therefore, its properties are enhanced by the introduction of additional components. Previously, straw, sawdust, shavings were added to give strength, later gypsum, cement, and lime were introduced.

Lime and cement mortar

Stucco cement-lime mixture It is most often used when performing plastering work in a room where the humidity level is increased, it is a good basis for decorative plaster, ceramic tile. Due to cement, the mixture becomes strong, and lime gives plasticity.

Used components and proportions: lime mixture, cement, building sand - 1: 1: 2–5.

Attention: May be lime-cement plaster m 100 and m200. It all depends on the amount of cement in the composition and its brand.

The method of composing lime-cement plaster:

- Mix dry components - cement and sand.

- Take strained slaked lime and bring it to the consistency of milk. To do this, mix it and water in equal volumes.

- Pour the resulting solution into a dry mixture.

- Mix all the components well, bring to the desired consistency, adding a little water.

Lime plaster technology

The whole process of plastering involves steps.

Preparatory

Before proceeding with the preparation of the solution, you need to choose the method of mixing and applying it to the surface.

For such mixtures, two application techniques are characteristic:

| Mechanized | Which involves the use of a special pneumatic tool. In this case, the workflow is shortened and simplified, and the employee’s strength is saved. |

| Manual | All work is done using simple tools, such as a trowel, grater, rule. |

So:

- Some are more comfortable using a roller or brush. To facilitate mixing of the components and obtain a homogeneous mass, it is recommended to use auxiliary equipment: a concrete mixer, an electric drill with a special nozzle, and a construction mixer.

- In preparation for plastering, an approximate amount of the required material should be determined. So, to perform insulation work using plaster, the flow rate of the solution increases compared to leveling the surface.

- The amount of mortar will also depend on the condition of the room, more precisely, the walls: for a new building, less mixture will be left than for surfaces requiring repair, additional processing, and leveling. For example, under the old coating there may be holes, cracks, the completion of which will require an additional part of the solution.

Work surface preparation

A more accurate calculation of the required material can be found by removing all additional coatings, scraping off the old layer of plaster. After that, the walls are cleaned, if necessary, then leveled and, at the end, they are primed (see Primer walls and all for that matter).

- Plaster easily lays on a concrete surface, but for some materials, with poor adhesion, a mesh is needed. For this, a special painting option is taken, but in the absence of suitable chain-link made of thin wire. The grid is fixed on the wall to ordinary screws, only sometimes - on dowels. The material is fixed around the perimeter, in some cases and in the center.

- For a wooden surface, instead of a mesh, shingles are used - a mesh of thin wooden planks. Such work, to create shingles, is painstaking, requiring skill.

Caution: The plaster is not applied to lime whitewash, it must be washed off or cleaned.

- When the walls are treated with a primer, then the next step for applying plaster is started only after this layer has completely dried.

- The preparation of surfaces for work by installing beacons is nearing completion, although this is an optional condition. Lighthouses help to monitor the evenness of the walls, well complement the work of the rule. So, the rule rests against the lighthouses, and without much effort makes the applied layer of plaster even. In the absence of these tools, they simply proceed to the next step.

- Lighthouses can be made from a working mixture of plaster, aluminum profile, wooden plank. They are leveled with a building level, glued to the surface. The height of the side of the profile determines the thickness of the plaster layer.

- Lighthouses made of plaster resemble a crest, they are obtained as follows: a vertical line is drawn, which is then cast with a solution and smoothed out by level. Lighthouses are located at a distance no wider than the length of the rule.

Preparation of a mixture for plaster

Many are afraid that they will not be able to cope with this step, believing that they will receive a poor-quality solution. But this is not so: just follow the kneading technology or follow the manufacturer's instructions. This applies to the dry mix.

Attention: For internal work, they often buy ready-made dry powder, to which only water is added, mixed thoroughly and that’s all - the mixture can be used. In this case, in order to get the correct consistency, you need to follow the manufacturer's instructions, which are described in the instructions.The construction mixer will help to make a homogeneous mass, without lumps.

If you decide to prepare the solution yourself, then carefully consider compiling the proportions. As a rule, at each working stage of plastering the same solution is used, consisting of a certain number of components. The difference is in the ratio of components and the density of the mixture.

Cement-lime mortar consists of the following ingredients:

- Slaked lime;

- Cement;

- Sand;

- Water;

- PVA, optional.

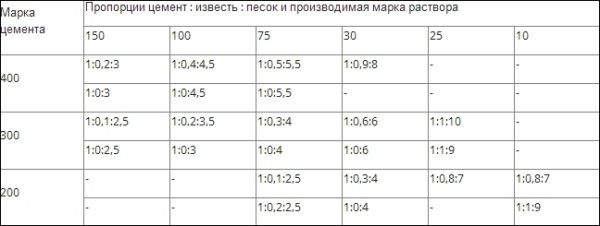

The proportions can be found in the tables of normative documents:

- In the absence of slaked lime, the mixture is obtained from ordinary lumpy lime. To do this, mix it with water in a ratio of 1: 3.

- When working with lime, it is imperative to use personal protective equipment: gloves, a respirator.

- An important point: water is added to the lime, but not vice versa. At this point, a reaction occurs, accompanied by heat generation, foam formation, and spraying. Therefore, the solution should be prepared in a deep container, which is closed by a lid. It is advisable to prepare the solution on the street. It takes about a day to complete all stages of the reaction.

- You can continue to work with the lime mixture only after a day. After that, the solution is filtered through a fine mesh or a thick layer of gauze. The resulting solid residue is slaked lime used for plastering. In it you need to add sand, cement, diluting with water to the desired consistency.

For various types of work, there are proportions of the main components - lime, sand, cement:

- Spray - 1: 0.5: 4;

- Soil - 1: 0.7: 3;

- The top layer is 1: 1: 2.

Attention: It is also worth noting that all proportions are not strictly regulated, they can be changed depending on the state of the mixture, the required properties. Also add ferozit 240 lime plaster thin-layer pieces 2. It all depends on what composition you want to get.

- So, to get a solid mass, increase the volume of sand, more sticky - lime. Plaster for the lower layer can be mixed from any kind of sand, while for the upper layer only fine sand will fit.

There is also a substitute for lime for plaster. But this is not quite a calcareous composition, additives spoil it. Limestone plastering is not difficult and therefore by looking at the photo you can make a quality composition.