How to plaster foam blocks according to technology

Exterior stucco foam blocks is quite important when decorating any building. After all, here you need to choose the right solution.

Today we’ll talk about the foam block than plastering, the opportunity to watch the video in this article will also be presented. And instructions will be given for the correct execution of the work.

The content of the article

How to improve the adhesion of foam concrete blocks

Before you think about how to plaster foam blocks with mortar, you need to know some of its properties. Not every composition will do. Foam blocks are made from different compositions and have various plaster compositions.

As a result, high-quality surface finish is possible far from any mixture of cement and sand. This is why stucco cracking on foam blocks (seeFoam houses: outdoor decoration - a variety of options).

Attention: In case of unsuccessful selection of finishing material, the plaster layer risks falling apart, especially from inclined surfaces that are aligned with a thickened layer.

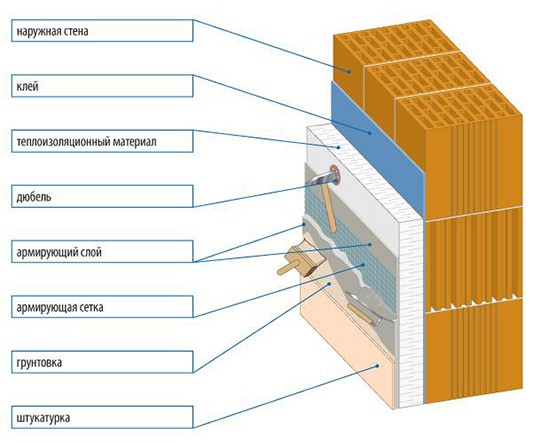

To increase adhesion - the ability of the surface being trimmed to hold the plaster mixture when there is a mutual adhesion of materials, there are two ways:

| First option | In the first method, special compositions are applied to foam concrete surfaces, for example, primers or concrete contacts; |

| Second option | In other cases, a reinforcing mesh is mounted. For this purpose, use a special stucco mesh, sold in hardware stores. You can also use a conventional nylon fishing net with a medium mesh size. |

Attention: If the surfaces are not prepared by any of these methods, then the plaster is applied layer by layer in several stages. First, a liquid layer is applied by spraying. Then - the main layer. At the end, a finishing layer is applied. Each layer should dry well.

Plastering foam blocks

Plaster for foam block is applied on a damp surface. Therefore, the surface is moisturized.

This work can be done with a brush, but it is more convenient and efficient to use a spray gun, which helps to achieve uniform wetting of the cellular structure of the blocks. All work can be done with your own hands.

Before starting the execution, it is recommended to watch photos and videos, then you can do everything correctly and the finish will be of high quality.

Although its price is not high, I don’t really want to redo it several times. Therefore, initially you need to do everything right.

Dew Point Selection

Before you think about how to plaster the foam block, you need to determine the dew point. If the definition is not correct, you risk that the plaster will begin to collapse quite quickly.

Foam blocks themselves are good heat insulators. But even through very thick walls, cold can penetrate the room.

Conductors of negative temperatures are also masonry seams. The cooling of the walls is greatly inhibited by the external plaster.

In turn, a powerful internal plaster layer will retain heat in the room, preventing the walls themselves from warming up directly:

- If, compared with the outer stucco layer, the inner layer is too thick, then the dew point will be exactly at the point of contact of the warm inner plaster with the cold surface of the blocks.This means that condensation will begin to form on the contact line of surfaces with a large temperature difference. As a result, the house will begin to damp.

- To ensure the optimal microclimate in the house, it is necessary to correctly correlate the thickness of the layers of the external and internal plaster. Best if exterior wall decoration will be twice as thick as the walls inside the building. Then the dew point will be shifted outward.

Finishing foam blocks of various types

In the case of using foam blocks made using cutting for construction, when plastering large flat surfaces, you can do without a reinforcing mesh:

- Such blocks have sufficient roughness to ensure good adhesion.

- The grid will need to be strengthened only where increased stresses are possible, for example, in the openings of windows and doors, in corners.

- If molding foam concrete is used, then to improve adhesion it will be necessary to sand the outer hydrophobic layer. In such cases, a good adhesion of the plaster layer to the blocks can be achieved by applying light mixtures with high adhesion or reinforcing mesh, strengthening it over the entire area.

Note: It is important to make the right choice of mesh. It must be resistant to alkaline conditions. Otherwise, the plaster will begin to crack due to a violation of the strength of the mesh.

Features of plastering

Using special plaster mixes with improved adhesive properties is the fastest and easiest way to finish foam block walls. On the packaging of the material should be indicated that this mixture can be used for foam concrete.

Mix the mixture according to the manufacturer's instructions. Before plastering, a deeply penetrating primer for absorbent surfaces is applied to the walls.

If the foam blocks are finished using an inexpensive sand-cement mixture, then you should pre-configure yourself to overcome some difficulties:

- Firstly, it will take much more time and labor;

- Secondly, it is necessary to strictly observe the production technology, since the wall of foam blocks instantly absorbs moisture, which leads to the quick drying of the plaster and its shedding.

To solve this problem, before starting the finishing work, a liquid solution of cement and sand is applied to the wall:

- Then, making sure that the mass adheres well to the surface, without waiting until it dries, the main plaster layer is applied. In this case, the liquid cement-sand mixture plays the role of a primer, which provides a good adhesion of foam blocks with plaster.

- In this case, the flow of moisture to the surface of the foam blocks and its uniform distribution over the entire contact area of the wall with the finish will be limited. This achieves grip quality.

- The use of acrylic primers instead of this solution is undesirable. Since in this case a waterproof layer forms, which will not allow even distribution of moisture, as a result of which cracks and shedding will begin to appear in the plaster layer over time.

- To give the facade of the plastered house a certain color can be painted. To do this, you can use silicone and acrylic paints, which have a vapor permeability.

Attention: Correctly applied plaster will help protect foam concrete blocks from the damaging effects of atmospheric phenomena and give the facade an attractive appearance.

Whether it is necessary to plaster foam blocks now you decide for yourself. Although it is better to do this, because its structure is porous and promotes the penetration of moisture. But how to plaster the foam blocks of the video, you can watch and do the job correctly.