Plaster plinth as a way to protect, strengthen and decorate

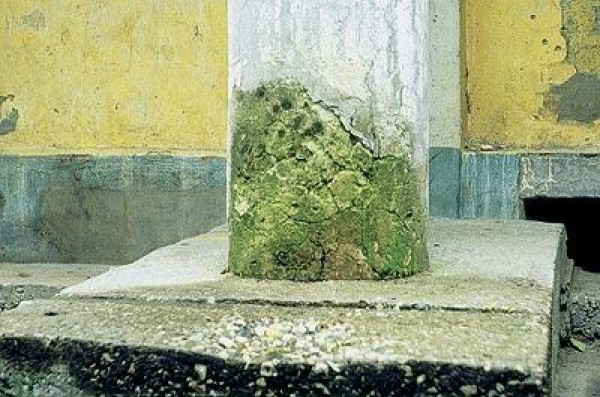

Over time, the part of the foundation protruding above ground level inevitably collapses under the influence of atmospheric phenomena, if it is not provided with reliable protection. From the aggressive influence of melt and rainwater, sunlight, subzero temperatures and other destructive factors, it can be protected by plastering of the base with your own hands.

This type of exterior decoration, in addition to protective, also performs strengthening and decorative functions. This makes it very popular with both private and municipal developers, because the house should be not only reliable and durable, but also aesthetically attractive.

The content of the article

Base plaster requirements

In order for the coating to serve for a long time and reliably, it is not enough just to follow the rules of preparation and application of the solution. It is necessary that the selected material in its composition and properties meet certain requirements.

What should be the base plaster:

- Moisture resistant. The lower part of the structure is more susceptible to moisture than other structures: snow, rain, melt water, often containing aggressive chemical compounds. The coating should withstand such effects, not to let moisture pass to the base.

- Durable. No less harmful can cause mechanical effects of a destructive nature. Plastering the plinth is intended to provide protection against them.

- Frost resistant. Plaster should withstand its repeated cycles of thawing and freezing without losing its properties.

- Resistant to UV rays.

- Resistant to fungi, bacteria, insects and plants that cause biological corrosion.

It is especially important to comply with these requirements when insulating the basement, since heat-insulating materials need to be protected from all the above effects even more than the base material - concrete tape, masonry or brickwork.

What materials to use

Based on everything said above, you can decide how to plaster the base of the house:

- Gypsum mixtures are not suitable for this purpose - they are afraid of moisture and do not have sufficient strength.

- Price polymer plasters taking into account that the layer should be sufficiently thick, unreasonably high. They can be used as a thin-layer decorative coating after the aging of the main protective layer.

- Remain cement based compositions. It is they that maximally correspond to all these conditions, while having a low cost and availability.

Ready-made compounds

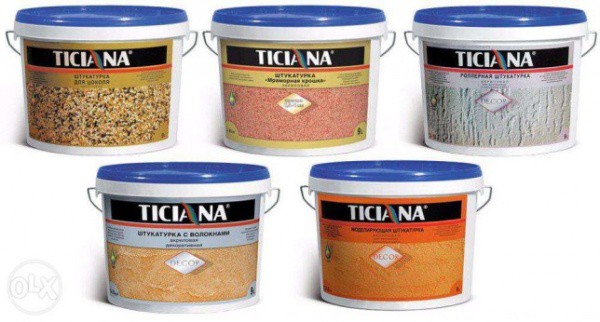

Many domestic and foreign manufacturers produce a special cement basement plaster, in which, in addition to cement and fractional sand, chemical additives are added to improve the quality of the finished coating and the adhesive properties of the solution.

The following brands were most widely used among specialists:

- Volma Base;

- Ilmax (Ilmax) 6820;

- Eunice Silin Basement;

- Sockelputz Knauf.

Some cement mixtures incorporate solid mineral inclusions (for example, marble or quartz chips), improving their strength characteristics and giving the surface decorative properties. But more often for decorative decoration of the lower part of buildings thin-layer polymer mixtures are used, which are applied to the surface leveled with cement compositions.

Another option for decorating the basement is that the cement coating has not yet dried using special rollers (see Rollers for decorative plastering and creating a relief surface), stencils, metal brushes and other devices give a certain relief. And its color can be changed by simple staining with persistent paints or by adding pigment to the solution during its preparation.

Homemade plaster for plinth

A solution for finishing the base can be prepared with your own hands, the benefit is that cement and sand are completely affordable materials. But there are several nuances regarding the brand of cement and the origin of sand. In addition, only these components are not enough, the solution must necessarily contain plasticizing and water-repellent additives.

The instructions below will help you cope with this task perfectly:

- Sift quarry sand (not river!) Through a metal sieve with small cells to free it from clay, plant debris, pebbles and other extraneous inclusions;

- Pour the sand into the container for the preparation of the mortar or into the concrete mixer, add the right amount of cement and mix the dry components;

Note. The proportions depend on the brand of cement. Three parts of sand are taken for one part of the M400 brand, if cement is M500, then the number of parts of sand can be increased to four.

- Next, prepare the liquid for kneading by adding plasticizing and waterproofing components to the water. It can be PVA glue and polymer dispersion Latex Profi. Also at this stage, you can enter pigments or colorants to give the plaster the desired color;

- The finished liquid is gradually added to the dry mixture and mixed, achieving the desired density.

For reference. The solution for the primer should be liquid, flowable, and for the covering layer - plastic, convenient for application and smoothing.

Plastering the plinth

Let's move on to how to plaster the base of the house. The process consists of several stages - surface preparation, primer, installation of beacons, applying the main and decorative coatings.

Preparatory work

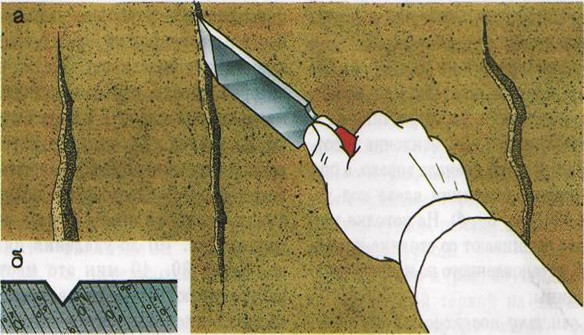

Preparation of the base consists in cleaning it. First of all, the dried out mortar is cleaned from brick or masonry, from the seams between the blocks. If the foundation is concrete tape with large cracks, then they expand - deepen and become wider in order to remove weakened areas.

Work is carried out by any convenient tool: a rigid spatula, a chisel, etc. Then from the obtained recesses and from the entire surface with a stiff brush, the remaining small particles of dust and sand, fragments of plaster are swept out.

Before plastering the basement base, it must be primed with special compounds (see Primer for concrete - preparatory stage for subsequent finishing), penetrating into the thickness of the base and strengthening it. This will also allow to bind the remaining dust on the surface and increase the adhesion to the stucco mixture.

Tip. When priming, special attention should be paid to seams, cracks, chips and other defects.

Instead of a primer, it is allowed to use a liquid working solution, which is applied by spraying with a brush or a broom.

Finishing work

Immediately after the primer layer has dried, work is started on the plastering of the base, which is performed in the following sequence:

- First of all, cement recesses, cracks, masonry joints are filled with cement mortar;

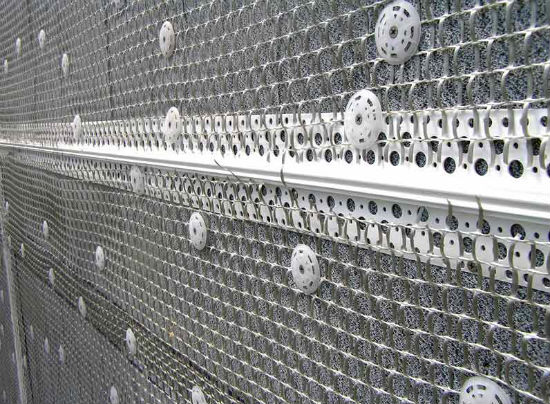

- Then, a metal reinforcing mesh is mounted on the base. Plaster on a grid is more reliable and durable;

- The next step - lighthouse installation. You can do this in any way convenient for you. For example, putting them on a plumb line, as is done with the plastering of internal walls. If a blind area has not yet been arranged around the house, you can drive straight pegs into the ground along a horizontal line drawn on the ground parallel to the base and at a distance of at least 2 cm from it. In this case, the space between the pegs and the wall is thrown with the solution from top to bottom, after which you need to wait for it to dry and remove the stakes;

- The distance between the beacons should be less than the length of the rule that will be used to level the solution. And the distance from the extreme lighthouses to the corners should be 20-30 cm;

- The most difficult thing is left, it remains to throw a solution with a thick layer between the beacons and level it with the rule.

Note. It is advisable to remove metal beacons from the coating, otherwise with time rusty spots will appear in their place. This is done 5-6 hours after application, and the remaining recesses are filled with a solution and leveled.

Further actions depend on how you are going to decorate the basement. If painting, tiling or decorative plastering for the plinth is chosen as the finishing finish, then the coating needs to create conditions for proper drying.

To do this, it is covered with a waterproof material to protect from rain and sunlight and wait 2-3 weeks depending on the thickness of the layer. During this time, the surface should be moistened twice a day with water. After drying, it is primed and a decorative coating is applied.

Note! In no case can you artificially accelerate the hardening and maturation of a solution by exposing it to a surface covered by heat guns and other devices.

But you can decorate the base in a different way. To do this, create a relief on a fresh layer of the solution by any means at hand. A lot of options.

For example, you can pre-make a stencil, the print of which will leave a stone or brickwork pattern on the surface. The same pattern is easy to apply with any long and thin object, making it grooves in fresh plaster.

You can also use a notched trowel or comb, a stiff brush or textured roller. Or with your own hands in rubber gloves depict on the basement an ornament, an abstract figure, etc.

The plaster is then dried, as described above, and if desired, painted in the desired color.

Conclusion

Plastering such a structure as a base is a great way to practice for those who want to gain skills in this construction field. A relatively small area, the absence of high requirements for surface leveling, work at ground level without the need for forests is a task just for beginners.

After watching the video in this article, you will be convinced that it is within your power. It is only necessary to take a responsible approach to the choice of materials and clearly follow the instructions for surface preparation.