Primer for concrete - preparatory stage for subsequent finishing

Building materials such as concrete blocks and monolithic concrete have a smooth surface, high density and low ability to absorb moisture, which makes them difficult to finish. To improve the quality of plaster, putty or painting, a primer is used for concrete surfaces.

What kind of material is it, what properties it should have and how to use it, we will tell in this article.

The content of the article

Types of primers for concrete

When carrying out various types of work on concrete, the surface must be carefully prepared for applying the finishing layer. This is easy to do with your own hands if you know the technology and choose the right primer. It is selected according to its purpose and composition (see Types of construction primers and their scope).

Appointment

The primer composition must have certain properties: increase the adhesion of the coating to concrete, improve its structure, and help reduce the consumption of finishing materials.

The following compounds have such properties:

- Deep penetration primer for concrete, the small particles of which penetrate deep into the pores of the material and clog them, gluing the top layer and forming a strong film on the surface. The penetrating primer increases the adhesion of the coated working surface and is used before finishing with lime-gypsum, gypsum, lime-cement plaster, ensuring its high reliability and durability.

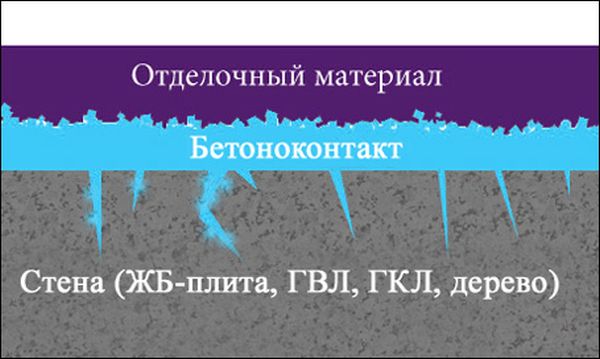

- Adhesive primers contain fractions of quartz sand, which give a smooth concrete surface roughness, due to which the applied coating adheres firmly to it and holds firmly for a long time. This composition of the primer for concrete provides excellent adhesion to gypsum, cement-sand and polymer plasterspaints.

For reference. Such primers are available in ready-to-use form and have a special name - Concrete Contact, Betocontact or Betogrunt. They are suitable for preparing for decoration and other smooth materials - planed wood, plasterboard and gypsum fiber sheets, tiles.

- Polyurethane and epoxy primers, leveling and hardening the concrete base. They not only fill pores and microcracks, but also increase the resistance of the surface to mechanical stress and the aggressive effects of various chemicals, therefore they are mainly used for finishing industrial premises.

Structure

When choosing how to prime concrete, pay attention to the composition of the product. The most common primers are made on an acrylic basis.

Among their advantages are environmental friendliness, lack of smell, the ability to dilute with water, high efficiency, optimal flow rate, affordable price. Their use can significantly reduce the consumption of materials used for finishing concrete surfaces.

Tip. If the surfaces to be trimmed are affected by fungus or there is a risk of mold on them, buy acrylic primer with fungicidal additives. Instructions for its use are described in detail on the packaging of the product, in particular - on preparing the surface for priming.

In rooms with high humidity (bathrooms, bathrooms, kitchens, pools, etc.) it is better to use silicone primers, which have good resistance to moisture and high vapor permeability.

To perform outdoor work, it is necessary to select the appropriate soil with a high content of gluing and film-forming components, which will strengthen the base as much as possible and will not allow it to collapse under the influence of atmospheric factors.

Note. Try to get all the finishing materials (primer, putty, paint) from one manufacturer. As a rule, they are issued in a complex and are compatible with each other as much as possible.

Application technology

The primer is available both in finished form and in the form of a dry mixture, requiring dilution with water or a solvent. In this case, it should be prepared immediately before use and in strict accordance with the instructions from the manufacturer.

There are a number of recommendations for the production of primers, the implementation of which guarantees their quality:

- A deep penetration primer on concrete is most effective when used in a certain range of temperatures and humidity. Therefore, work should be performed only with positive air temperatures (optimally from +5 to +25 degrees). And increased humidity can lead to the formation of a foaming layer on the surface being trimmed.

- The foundation before priming must be prepared: clean from peeling paint or plaster, greasy and bituminous stains, dirt and dust. The easiest way to do this is with a grinder and an industrial vacuum cleaner, but you can also do it manually.

- Apply the primer with a spray, brush or roller, trying to maintain uniformity of the layer.

- The number of layers depends on the state of the base - for loose and crumbling surfaces, they may require several.

Tip. The need for applying the next layer is determined by the type of dried surface. If the entire primer is absorbed without a trace, continue to work. The readiness of the base for subsequent finishing is indicated by the characteristic luster on its surface.

The consumption of the product indicated on the package is of average value and may in practice be less or significantly more depending on the condition and density of the base.

Proceed to the subsequent finishing is possible only after the final drying of the primer. But it’s not worth delaying it so that the dust does not settle on the surface again, which impairs the adhesion quality.

A base prepared in this way can be plastered, puttied, painted, and wallpapered. However, it should be remembered that thin paper wallpaper and paint in several layers will not hide large pores and cracks on the surface. Therefore, it is better to pre-align and primer again.

Another important tip: when working with a primer, observe safety measures. It may contain irritating substances, so try to prevent the mixture from getting on the skin and mucous membranes.

Conclusion

The use of concrete primers guarantees a better and more durable finish. It is hardly worth giving up on them, given such advantages and the relatively low cost relative to other materials.

The main thing is to choose the right composition, taking into account the subsequent decoration and operating conditions. The video clip posted in the article will help you with this.