Installation of beacons for plaster - all the nuances and secrets

High-quality wall decoration involves their perfect leveling and creating the smoothest surface without sinks and sagging mortar. This is quite difficult to achieve, but the task is greatly simplified by special guides mounted on the trimmed plane - the so-called beacons.

We suggest that you carefully read the information below and watch the video - installation of beacons for plaster.

The content of the article

What are lighthouses and why are they needed

Lighthouses are a kind of rails, based on which, the plaster mortar is leveled by the rule on the wall. If you set them strictly in one vertical plane, then there will be no problems with leveling the surface with your own hands, the work will take a minimum of time.

Of course, you will have to tinker with the installation of lighthouses, but this time will more than pay off in the future, and will positively affect the quality decorative wall decoration.

In the past, stucco guides were often made of even wooden blocks of the same cross section, of gypsum, or of the same mortar that will be used for leveling. Now there are metal beacons on sale that greatly facilitate and accelerate the work.

However, they have certain shortcomings, which we will talk about a little later, so the old methods are still in demand among many masters.

Installation technology

Before telling how to set up beacons for plaster, let us dwell on surface preparation, the choice of tools and consumables.

Which beacons to choose

To begin with, you should decide whether you will use ready-made metal, wooden guides or independently make them from plaster mortar.

Each method has its advantages and disadvantages:

- In the first case, the work will take less time, but the beacons after leveling the surface will have to be removed from the plaster layer with subsequent sealing of the formed defects.

Note. Conscientious masters to the question of whether it is possible to leave lighthouses in plaster, answer negatively, since over time they begin to rust, and rust spots can come to the surface. And sudden changes in temperature can lead to cracking of the solution along the metal guides. Although in constantly heated dry rooms the risk of such consequences is low.

- The method of making beacons from a solution is more time-consuming and lengthy, but you do not have to do the extra work of extracting them.

- Wooden lighthouses are almost never used today, since wood is characterized by its ability to absorb moisture and deform, which negatively affects the quality of alignment. They find active use only when decorating wooden houses with clay stucco.

To make a choice, watch a video on how to put beacons under the plaster.

Training

To work, you will need a building level (preferably a laser), a trowel, a spatula and two rules - long and short. The distance between future beacons depends on the length of the short one with which the solution will be leveled: it should be 10-20 cm less.

You also can not do without a punch, dowel nails, roller for primer, a large bucket and a drill with a nozzle for mixing the solution.Before installing plaster beacons, walls need to be prepared.

The preparation process includes the following steps:

- Inspection of the surface for gross defects and deviations from the level;

- If solution flows, protruding masonry elements are found, they are knocked down using a chisel and hammer;

- After that, the surface is cleaned of dust and must be primed to ensure good adhesion of the stucco mortar to it.

It is important! Neglecting this step entails the risk of flaking the plaster from the wall in the future. If you do not want to do the repair again from scratch in the near future, be sure to prime the walls before installing the beacons.

Installation of metal beacons

Ready-made beacons are an L-shaped or T-shaped perforated profile made of galvanized metal. The galvanizing layer protects the metal from corrosion, but during the installation or leveling of the solution it is easy to damage it, therefore the appearance of rust with time is quite possible, and therefore it is recommended to remove the profiles from the plaster when it sets.

When buying beacons, make sure they are even and tough enough. Products made of thin metal during plastering can bend, which will degrade the quality of the finish.

Now it's time to tell how to put beacons under the plaster - the video and detailed description will help you cope with this task without any problems.

So, first you need to mark the position of future lighthouses on the wall, drawing vertical lines on it. The first should be located at a distance of 20-30 cm from the corner, all subsequent ones should deviate from the previous one by the length of the rule minus 10-30 cm. It is most convenient for beginners to work with a step between beacons of not more than 1.5-2 meters.

Now you need to set landmarks for lighthouses by level. This is a very responsible and meticulous work.

The following instructions will help you complete it correctly:

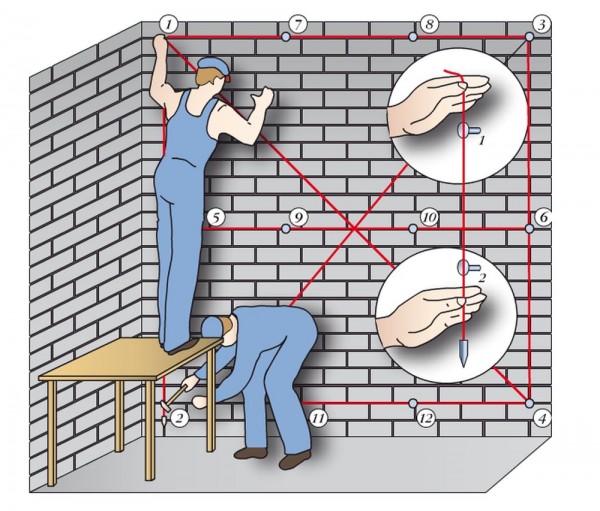

- On the drawn lines, having retreated 20 cm from the ceiling, drill several holes for setting landmarks - dowel-nails. For a wall with a height of 2.5-2.7 m, 5-7 such holes are enough;

- Drive dowels into all holes, screw the self-tapping screws into the upper and lower extremes;

- Pull the fishing line between the screws in all directions: vertical, horizontal and diagonal;

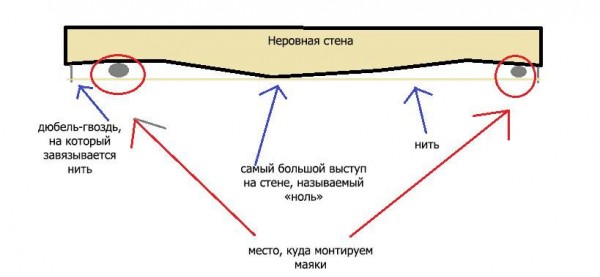

- Identify the most protruding section of the wall;

- Using a level and a screwdriver, with which the screws are screwed into the dowel or unscrewed from it, achieve such a position that all the stretched threads are located in one vertical plane and are separated from the protruding section by the minimum distance for the plaster;

- Screw the self-tapping screws into all the other dowels so that their hat is at the same level with the fishing line stretched vertically. Thus you will achieve their location in one plane. Having finished work, once again check the correctness of the level and, if necessary, correct their position.

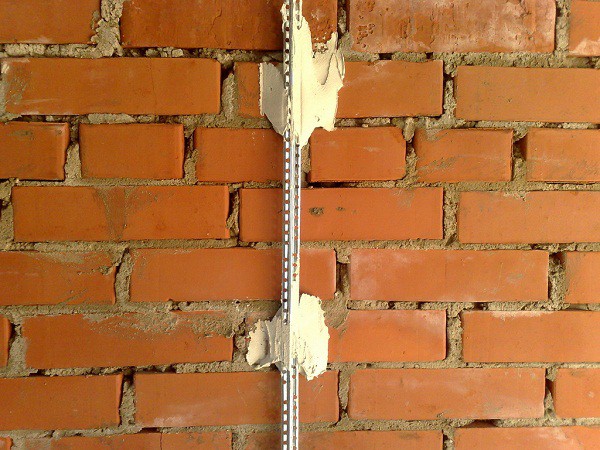

Let you spend a lot of time and patience on this work, but now the question of how to put beacons for plastering correctly will be solved quickly and simply. You will only need to put the profiles on the heads of the screws so that they abut against them along the entire length, and fix it on the wall with a solution.

To do this, the solution prepared in advance is applied in heaps between landmarks, a lighthouse is installed, a long rule is pressed against the hats of the screws, at the same time making sure of their correct vertical position. Excess solution protrudes through the perforation holes.

To fix the guides in a predetermined position, after the solution has set, they are fixed with dowels or additionally coated on both sides so that the solution does not extend beyond the beacons.

Tip.To reduce installation time, use gypsum or alabaster for fastening - they dry much faster than the cement mixture.

The process of plastering lighthouses is a topic for a separate discussion. Here we recall that when the solution on the leveled wall seizes, but has not yet completely hardened, the guides should be removed from it.

This should not cause difficulties: it is enough to pick up fresh plaster from any edge, expose the end of the lighthouse, and then gently and gradually tear it off the wall.

It is unlikely that the product can be reused, since it is uniquely deformed during dismantling. But its price is not so significant as to save on it.

The longitudinal recesses remaining from the lighthouses are cleaned of the remnants of alabaster, moistened with water from a spray bottle and sealed with a basic solution. Self-tapping screws before this also need to be unscrewed.

The device beacons from the working solution

The preliminary stage, namely the installation of landmarks for lighthouses, in this case is the same as in the case described above.

Then we proceed as follows:

- Knead the solution and apply it in heaps on the protruding hats of the screws;

- When he grabs lightly, remove excess protruding beyond the hats;

- When the marks have solidified well, attach a vertical rule to them or a level wooden lath vertically and throw a solution into the space between it and the wall;

- Tap the staff with a hammer along the entire length to even the resulting strip of mortar, wait until it starts to set and carefully clean;

- If voids and shells remain on a makeshift lighthouse, rub them with a trowel;

- Repeat the procedure for all the guidelines.

If you have metal PP profiles, it’s easier to do this: pour the solution along the entire height between the reference points, grease the profiles inside with oil and press them into the solution, making their inner surface come in contact with the self-tapping screws. For this, the profile is cut off slightly less than the required length and moves up and down so that the solution inside is evenly distributed.

Excess mortar on the sides must be removed and the profile carefully removed after a while. You will get even lighthouses made of plaster, which, after aligning the entire plane of the wall, will not need to be removed.

If something in the description remains incomprehensible to you, and you did not fully understand how to install beacons for plastering - the video will help you fill in all the gaps.

Conclusion

Qualitatively plastering the surface is difficult not only physically. This work requires precision, accuracy. The smoother the walls will be, the less problems and financial costs that will arise with subsequent finishing - putty, cladding, wallpaper decoration.

Installation of beacons allows to reduce labor costs, consumption of plaster mixes and time for work. The proposed videos in this article clearly prove this.