Types of plaster for walls: consider in detail

The methods for plastering walls are quite different. Here, the choice of plaster for the walls is of no small importance. Its method of application will depend on this.

We will consider all these issues today. You will learn which material to choose and how it is applied. Also, in the video in this article, you can watch individual moments of this work.

The content of the article

Types of wall plasters

The best type of plaster for walls one that will suit not only the application material, but also the design of the room. Any of them is applied with your own hands. The price of work in this can be significantly reduced.

It's just that you need to choose the right material and do it according to technology. The following is a complete guide on exactly these issues. Plaster mixes are divided:

Dry plaster

Drywall sheets are also called dry plaster. This is a fairly simple wall plaster, here you will not even be interested in the application layer, it is important to simply mark the application plane and make the frame correctly.

So:

- They are used for wall cladding indoors (see Facing walls with drywall: do it sequentially) There are wall drywall and ceiling, they have different thicknesses, and therefore different weights. The installation technique of drywall sheets allows you to quickly and with high quality to make wall and ceiling cladding.

- Given the fact that the sheets are attached to a special profile designed specifically for this, such a complex is called a plasterboard system. The installation technology of such systems is designed to the smallest detail, which allows such installation even by not experienced craftsmen.

- Drywall sheets are attached to the profiles using metal tapping screws designed specifically for drywall systems. The final step in the installation of drywall systems is puttying (see How to putty drywall - basic rules and techniques).

| Advantages | It:

|

| disadvantages | Along with the advantages, drywall has several disadvantages:

|

Wet plaster

The options for wall plastering here are quite wide and this option is used most often. Here, plastering of walls with heating can be done, for this there are special warm plasters, plastering for arbolitic walls can also be done. Let's look at why this option is attractive and where it will not work.

Advantages:

- Pretty high durability. This material will last a long time and its support will not take much time;

- Universality. Wet plaster Suitable for almost any surface. Moreover, the laying system is not fundamentally different;

- Ease of applicationis also a big plus. The work can be done not by a specialist, this will save considerable money.

The disadvantages include:

- Weight gain of the structure.

- High price.

- The duration of the process.

Attention: Choosing this option you should immediately pay attention. That this mixture is for internal external surfaces. Therefore, take the option you need.

Wet plaster is divided into regular and decorative:

- The effect of ordinary plaster is a flat, smooth surface designed for painting or wallpapering.

- To give the building an attractive appearance, they use a special type of monolithic plaster - decorative. Decorative plaster may differ in composition of materials and in the appearance of the resulting surface.

Depending on the main binder component, which is used in the preparation of plaster, this mixture is divided into:

| Calcareous | Lime is a material that has been tested for centuries, therefore, it is not surprising that lime plaster mixes are used today. The solution is obtained by mixing river sand with milk of lime. Ready-made dry calcareous mixtures of industrial manufacture can include synthetic fibers that increase the strength of the plastered surface. |

| Acrylic | They have good adhesion to all known building materials, are characterized by high elasticity and mechanical strength. |

| Polymer cement | Thanks to polymer additives, the traditional cement plaster mixture has acquired a number of additional characteristics that improve its properties. |

| Silicone | They are based on silicone resins. These plasters are characterized by increased resistance to aggressive environments, as well as resistance to damage by fungus, mold and rot. |

Caution: The decorative option can help you make almost any plane. It can be a Japanese wall plaster or any other option. So from the point of view of design, it is almost universal.

Color painted plaster

The basis of colored plasters is acrylic, as the main binder, as well as quartz sand and dye.

So:

- As a rule, such putties are ready for use and are intended for finishing window and door openings, as well as surface finishing inside buildings.

- Facade pictorial plasters, depending on the application method, make it possible to obtain decorative planes with various patterns. The bark beetle and pebble surfaces are very popular.

Stone plaster

The property of stone plaster to imitate the stone coating of walls, both inside and outside buildings.

So:

- Work begins with marking the rows of the future pattern of stone coating, using a marking cord for this.

- After that, a layer of the selected plaster coating is applied to the wall. After the layer of plaster has set, but not completely, they start cutting stone rows.

- Having fixed an even rail or rule along the contour of the drawing, using a cycle or other sharp and reliable object, remove the plaster coating to a depth of not more than 1/3 of the total thickness of the layer.

Terrazitic (lime-cement) plaster

This type of plaster mix can be used for facing facades of buildings and structures. It allows you to plan rock facades on facades.

- Given the fact that such plaster has significant weight, the surface is carefully prepared. Shallow notches are made on it, with a step of 3-5 cm, located horizontally. This rule applies to all types of surfaces, including concrete.

- Notches on concrete surfaces are made with a chisel and hammer, but you can also use a hammer drill.

- Before applying a layer of plaster, the wall is wetted with water. The first stage consists in applying a spray layer, and after 15-20 minutes the main decorative layer is applied.The next step is to process the decorative layer in cycles. As a result, a smooth, sparkling surface is obtained.

- As a result of driving a tool into a grasped cover, a chipped stone effect is obtained. In the final phase, the plane is sandblasted.

Sgraffito - art plaster

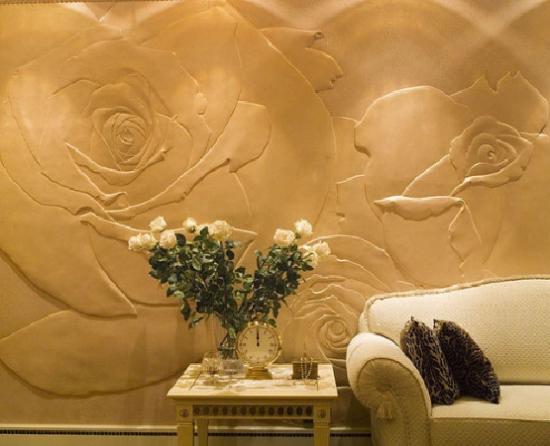

To obtain a relief coating having a specific pattern or pattern, you can apply a certain type of plaster coating called sgraffito.

- The technology is based on the process of applying several multi-colored layers, with the partial removal of some layers to obtain an ornament.

- When applying this technique, apply up to six layers of plaster of a different color, with the upcoming leveling of each layer. Then, a drawing is applied to all layers of plaster using a stencil and pigment powder or chalk.

- After the appearance of the contours of the drawing, with the help of a special tool, plaster layers are sampled in certain places. The result is a pattern with colorful elements.

Attention: In this option, correct and high-quality preparation of the application plane is quite important. After all, removing plaster layers, it can be folded. Priming the plane in this option is mandatory.

Venetian stucco or liquid marble

Basis venetian plaster marble flour is included, and the binder may be acrylic or lime.

So:

- The technology involves the application of many very thin layers with the obligatory polishing of each layer. The result is a textured layer with exceptional visual depth and a glow of each layer that has its own texture.

- Applying this type of plaster requires high professional skills, since you have to work with rather expensive materials.

- The result of such work will be a 5-mm layer of plaster having a pearly shimmer, which cannot be compared with any other coating.

How to choose plaster

The construction market has such a variety of building materials that differ in application methods that the consumer is not able to choose the right material, because he is tormented by the same question - which of these plaster materials is better?

After all, it can be simple wall plastering, and you can make a complex point of view of complexity. It is difficult to give an unequivocal answer to this question, because all plasters have their compositions and are designed for certain operating conditions.

- A lot depends on what goal is set and whether this goal can be strengthened by financial capabilities.

- The issue of harmony and combination of styles also cannot be moved to the last place. It is hard to imagine an expensive Venetian in an ordinary apartment. Its rightful place in the halls and living rooms of large houses is akin to palaces, because only in such conditions is chic appropriate.

- A lot depends on what goal is set and whether this goal can be strengthened by financial capabilities. The issue of harmony and combination of styles also cannot be moved to the last place. It is hard to imagine an expensive Venetian in an ordinary apartment. Its rightful place in the halls and living rooms of large houses is akin to palaces, because only in such conditions is chic appropriate.

Plaster wall alignment

Types of plaster for walls are quite different, but they have one thing in common, it is the alignment of the plane. Alignment of the wall with plaster will be required if, when conducting an inspection using a special tool - a rule or a building level - strong curvature, unevenness and surface defects are found that cannot be fixed with simple putty.

Before you begin to align the wall, we advise you to pay attention to the following important points:

- During operation, you should be extremely careful and cautious, especially when it comes to knocking down old plaster, located under the ceiling of the room and in places where electric wires pass to the outlet, switch. During the dismantling of the old plaster layer, electricity must be completely de-energized.

- In order to create good adhesion, i.e., adhesion of the stucco mixture to the base, preparatory work is carried out, which consists in creating a rough surface.

For each type of material, the walls use their own methods of improving adhesion:

- On a concrete wall, notches are made or they are tightened with plaster mesh;

- The wooden surface is covered with shingles;

- At the brick wall, processing, deepening the seams;

- Together the contacts of the wooden surface and the stone or concrete section are laid with plaster mesh tapes, while their width is not less than 20 cm, and the mesh size is 1x1 cm.

- The required thickness of the leveling layer is determined by hanging the surface with a plumb or a building level. If necessary, then fix the beacons, which can be taken pieces of plywood, working plaster mortar or screws screwed into dowels.

Attention: If the beacons are made of plaster mixture, then before the start of the main work they will be given sufficient time to dry. Lighthouses from plywood or self-tapping screws should be removed before the grouting step. This is done in order to exclude the appearance of rust spots from poorly processed screws.

- When carrying out plastering works by the builder for the first time, there is a need to install beacons, which are taken as metal profiles. They will determine the design thickness of the plaster layer. The most commonly used profile is marked as PM - 21 × 6 or PM - 26 × 10, where 21 and 26 are the number of the width of the base, 6 and 10 are the height of the beacon.

- To apply a thick layer of plaster, it is recommended to use beacons 10 mm high. As for the length of the profile, they take three meters, cutting off the excess with scissors for metal. The method of installing beacons is vertical, with fixation on the wall in several places, and also can be frozen by mortar.

Cleaning the walls after plastering is also worth it. To do this, mainly dyes or varnish are applied. So look at the photo and make your choice.