Mechanized wall plastering: do it yourself

Mechanized wall plastering will significantly reduce the time required to complete the work. And it will be much easier to do this. If you have a large amount of work, then the purchase of the device will be justified and the finish price will not be high.

Today we will tell you how to plaster walls in a mechanized way. You can also visually see this on the video in this article and photo.

The content of the article

Mechanical plastering

Plaster is mechanically applied in stages, here it is also necessary to prepare the plane for application, just the coating itself will be applied quickly. All stages are quite important, because the coating must adhere and have the correct shape, the presence of inflows is not allowed.

Although mechanized plastering will not always be cost-effective, you need to look at the place of work in this matter. Let's deal with this work in more detail.

Advantages and disadvantages of the plaster machine

In this section we will consider what mechanized wall plastering is, the pros and cons of this method of application.

Mechanized plastering in construction unambiguously leads to an increase in productivity and to an increase in the quality of work performed. First of all, this is due to the fact that the direct participation of a person is minimized in technological processes.

In addition, the use of a plastering machine provides the consumer with a number of advantages that are unattainable during manual work:

- Use of a plastering machine (see Apparatus for applying plaster: features of use) provides a flat surface, such quality manually can only perform high-class plasters;

- The solution in the machine is constantly mixed and passes through a filter before being fed to the wallin which lumps, pebbles and other impurities remain, this also positively affects the quality of the work performed;

- Significantly reduced timereserved for the performance of a given amount of work;

- The alignment and grinding operations of the applied solution disappear;

- Significantly improves adhesion between plaster and surface, this is achieved due to the fact that the solution is supplied under pressure.

- High adhesion provides a long service life of the plaster coating;

- The use of a plastering machine reduces the amount of mixture needed to be applied to a wall surface., since there is no need to fix defects that, one way or another, arise when applying the coating manually;

- There is no need to hire a large number of plasterers to process the walls in the room.

But it should be noted that the machine for applying plaster has some disadvantages. Before deciding on the method of applying the solution, you need to know the following disadvantages of mechanized wall plaster:

- the machine for applying plaster has significant dimensions, and the weight is such that to move even a mobile device, it is necessary to attract two or three assistants;

- some cars operate on voltage of 380 V, which is quite difficult to ensure during repairs in a house or apartment;

- after washing, about 30 liters of water are needed to wash the machine;

- the high rate of work is limited by the fact that the finished mixture must be used within one hour;

- in operating mode, the machine makes a large amount of noise, which limits its use in a residential area.

Where is the stucco machine used

Equipment of this type is popular with teams engaged in repair and construction works. The use of such a machine can significantly reduce the time spent on plastering.

In addition, the quality of the coating does not cause complaints from the customer. It should be noted that this device is widely used and, we can say that it is a universal assistant to the builder-finisher.

The machine for applying plaster mortar can perform the following work:

- application of solutions on the basis of gypsum and cement on the surface of the walls;

- priming and puttying (see Mechanical putty for walls);

- painting the surface of walls and ceilings;

- arrangement of thermal insulation;

- mixing and applying to the surface of reinforcing and adhesive mixtures;

- filling the floor;

- obtaining a thin layer of plaster;

- execution of floor screed from cement and concrete.

By the way, this is not a complete list of works that can be performed using a plastering machine.

Technology for applying plaster using a machine

The mechanized method of applying plaster involves the correct order of work. Before you start using the machine for applying plaster mortar, you need to place beacons around the perimeter of the surface. This operation greatly simplifies the process of plastering and further leveling.

You can do the work on the "eye", but later you have to use the level. The machine allows you to apply a layer with a thickness of 3 to 20 mm, this size is determined by the state of the wall surface and, of course, by the wishes and requirements of the customer. After the plaster is applied to the surface, it must be puttied and leveled.

How to choose a mixture

For machines designed for applying plaster on wall surfaces, manufacturers produce mixtures of various types - liquid and dry. They are used to work with surfaces of various types, for example, made of cellular concrete, silicate brick, reinforced concrete structures. The solution can be used at temperatures from +5 to + 30 degrees Celsius.

Plastering walls using a machine, possibly using several types of mixtures:

- Gypsum and cement-sand are mainly used (see Cement-sand plaster: material features) These names speak for themselves. The first is gypsum, the second is cement and sand, mixed in certain proportions. The composition of the mixtures may include a variety of additives that regulate the drying rate and determine their ductility. It should be noted that the main parameters of these materials vary greatly.

- The cement-sand mixture is used when applying plaster using a machine. This composition has high strength, weather resistance. These properties allow it to be used when decorating pools.

- By the way, there is one subtlety, if the plaster is applied by machine, it is advisable to use the mixture supplied in large bags, as it is more uniform. Using such a mixture, one must be prepared for the fact that after it dries, it is necessary to apply a layer of putty on it. Such mixtures can be used to decorate external walls, facades and rooms inside the building.

- A composition based on gypsum can only be used for interior decoration. Gypsum mixture compares favorably with cement-sand in that the creature dries faster.

Attention: But when deciding on the use of gypsum plaster, you need to remember that it is afraid of moisture and it is impractical to use it when decorating rooms with high humidity, for example, bathrooms.

- However, gypsum plaster has a high porosity. This allows you to apply a thick layer of the solution, without fear that it will crack or peel off over time.

- Using gypsum mixture will allow you to get a perfectly flat surface almost immediately and, quite possibly, no additional operations are required.

Surface preparation for work

Before starting work on plastering, it is required to clean the surface from traces of the old coating, glue, mortar and other interference.

Caution: If metal parts that cannot be removed come to the surface, they must be cleaned from rust. It is also necessary to remove the tubercles, fill the voids and cracks that are on the surface.

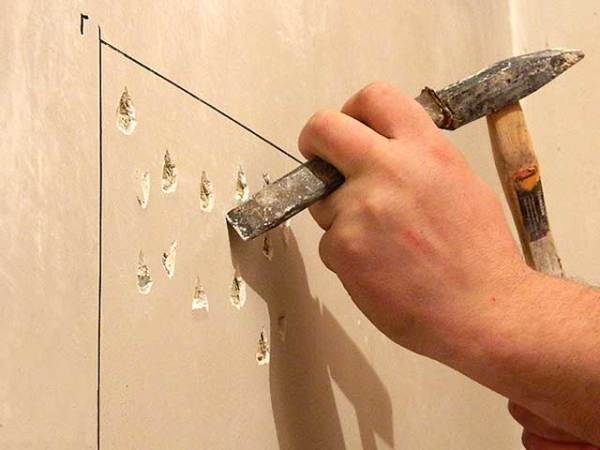

- The application layer is immediately determined, for this you just need to pull the line along the diagonals and use the level to put it in the axis. Then you will immediately see the required layer.

- Walls rebuilt from cinder blocks, bricks and other materials that have an uneven surface, then they must be treated with special compounds that ensure the removal of building dust. This work must be done using a spray gun that works using compressed air.

- Surfaces made of concrete monolith or lined with drywall must be primed. This work can be done with a brush or roller.

- It makes sense to reinforce joints and cracks with a special mesh with a mesh size of 5X5 or 10X10 mm.

- In order to get the perfect surface, you need to check the horizontal and vertical walls. To do this, use a building level of up to 3 meters in length, a template and a marking cord, you may need to use a hydraulic level. As a result of this check, it will become clear which part of the wall protrudes most.

- To check the angles apply special patterns and rules. After the check is carried out, at the corners installation of beacons.

- Before applying the solution to the surface, it must be covered with a layer of soil and allowed to dry. The primer enhances the adhesion of surfaces and will be the hall of durability of the coating. When choosing a liquid, it is worth giving preference to deep penetration material.

Equipment setup

Before you start working with a machine for applying plaster, you must not only deliver it to the place, but also perform a series of operations that ensure its greatest effectiveness.

- This device, as part of its design, has a container for mixture and water, which come in strictly specified proportions. As a result of this, the resulting mixture has the required density. Constant mixing leads to the fact that it loosens.

- After that, the finished plaster mixture is sent to the place of work, for this they use a special hose. Using various types of nozzles, the plaster is applied to the walls.

- All work related to the plastering machine must be carried out in accordance with the instructions for use of the machine and safety regulations. That is, the device must first be connected to the electric power supply and water supply. Only then dry gypsum or cement-sand mixture is poured into a special hopper. Additives can also be added there.

- If there is no water at the construction site, then you can use a pump, which, as a rule, is included in the delivery of the plastering machine. With it, you can ensure the supply of water from any source, for example, from a barrel.

Application of the solution to the prepared surface

Since you work with the mechanism, your attentiveness will have a great influence here, if you overexpose in one place, then it will be necessary to fix everything manually. Therefore, mindfulness is quite important here.

The solution is applied to the wall as follows:

- The plaster gun through which the finished mixture is fed must be located at a distance of about 20 - 30 centimeters from the surface to be treated.

- The gun must be positioned so that the plaster stream hits the wall at an angle of 90 degrees, that is, perpendicular to the wall plane.

- The plaster begins to be applied from corners and butt joints with other walls. During the execution of this work, it is necessary to constantly ensure that the new layer covers the previous half.

Caution: The thickness of the layer is determined by the speed of the gun relative to the surface.

Surface alignment

The time it takes to level the mortar on the wall is determined by the nature of the applied mixture and usually takes up to one hour from the moment it was applied to the wall and it has not lost its fluidity. After the mixture is applied to the wall, it must be aligned, focusing on the previously installed beacons.

To perform this operation, you must have at hand such a construction tool as:

- rule

- spatulas of different sizes;

- ironers.

After applying the plaster to the surface of the wall, it must dry to a certain state. While it dries, you can start preparing the next sections or processing corners and joints.

The distribution of the solution over the surface and its alignment is performed using a rule in the form of the letter h. If it turns out that in some areas the layer of the applied mixture is insufficient, then it is necessary to apply it again, until the wall surface is completely leveled.

Cutting the solution after applying it to the wall

About 40 minutes after applying the solution or 20 minutes after leveling, you can trim.

- To do this, apply the trapezoidal rule (cutter). With its help, the final formation of the surface of the applied plaster occurs.

Attention: On a flat plane, it allows size fluctuations based on 2 mm by 2 pm, on complex, curved planes, fluctuations within 2 mm of the size and shape of the template are allowed.

- Before cutting, it is necessary to check the condition of the applied mixture. To do this, you need to attach the rule to the surface and drag it a little. If the tool cuts off the outer layer and does not drag the main layer of plaster, then, then, everything is in order and you can proceed to the operation itself.

- Otherwise, you need to wait for some time, during which the solution will “bind”. If large efforts are required to cut off the outer layer, then the solution has dried up and a sponge will have to be used to remove tubercles and other defects.

A video on the mechanized application of decorative plaster will show you the whole order of work. Everything can be done with your own hands, and this will guarantee the quality of the work. The most important thing is not to rush and do everything consciously, the instruction will help you in this matter.