How is stucco wall plastering done

The technology of wall plastering with a rotband is similar to the execution of work and other mixtures. How to plaster a rotband and will be described below.

You can watch the video in this article and the photo, then it will be much easier to make the work. Everything is done in a certain sequence, the instructions for use eat on each package of this composition.

The content of the article

Rotband Characteristics

For plastering walls, cement-sand are mainly used (see Cement-sand plaster: material features), lime-sand, as well as cement-lime-sand mixtures. All of them have a number of drawbacks consisting in the formation of cracks.

Such mixtures have low ductility and not high manufacturability, which leads to the expenditure of large forces and energy when working with them:

- Gypsum-based solutions replaced traditional mixtures (cm. Dry plaster gypsum mixture: features of use) Modern compounds are more plastic, do not crack and do not shrink. They are so easy to handle that a novice master can work with them.

- Bag "rotband", weighing 30 kg, is within 180 rubles. With this amount of plaster, about 3.5 square meters of walls can be treated by applying a layer about 1 cm thick.

- Gypsum-based plasters have lower density, compared with cement, which reduces the load on the whole structure as a whole. In addition, they harden earlier than cement, reducing the time of construction work.

- Working with the "rotband" is more convenient and faster: when applying a layer with a thickness of about 2 cm, the plasterer is able to process up to 15 square meters of the surface, and when using a normal solution - no more than 10 square meters.

Plastering

Plastering the walls with a rotband video will help to do all the work yourself. It is no different from applying a cement composition. It’s just that the surface is smoother. There is less fraction.

Start of work: surface preparation

It is desirable to carry out plastering work at a temperature of about + 18-22 ° C and a relative humidity of about 60%. The plaster is applied to the rotband on a dry, dust-free surface. If it is a concrete base, then notches should be made on it.

So:

- The surface is cleaned of dust, dirt, traces of paint, as well as grease stains and covered with a deeply penetrating primer.

- After the primer has dried, you can set up beacons (see Installation of beacons for plaster without problems) As beacons, metal profiles are used, which are set strictly vertically and in one plane. In the future, beacons will serve as a support for the rule.

- Metal beacons have good strength, they are easy to install, but this increases the consumption of stucco mixture by 1.5 times. When buying lighthouses, you should pay attention to their evenness. Sometimes outlets do not pay much attention to the transportation process, as a result of which, deformation of lighthouses is possible.

- The process of installing beacons does not hasten, as this greatly affects the quality of the final result.

- The main task of the master is to set up the beacons as evenly as possible. For this purpose, you can use the building level and a long rail. Without problems, you can use the rule with an indicator of vertical and horizontal level.Its length should be 10 centimeters less than the length of the beacons. Lighthouses are displayed vertically in increments of 1 to 1.5 meters.

- Metal lighthouses are installed on stucco cakes from the "rotband". The plasticity of the cakes allows them to be set strictly vertically and evenly using the rule. To do this, the rule is attached to the lighthouse and pressing it against the wall, control the evenness and verticality.

- The gaps between the wall and the lighthouse should be filled with plaster mortar, and it is advisable to remove excess mortar.

- If the walls have large irregularities, then before installing the beacons, the surface should be leveled, especially in places where the beacons are installed. To do this, from bottom to top, at the installation site of the lighthouse, the stucco mixture is applied in a small strip, about 50 mm wide. Lighthouses are installed after the strip has grasped well.

- If the length of the aluminum rule exceeds 2 meters, then beacons can be installed in increments of 1.5-1.8 meters.

- With a wall length of up to 4 meters, it is enough to install 3 beacons, while the extreme beacons are installed at a distance of about 20 cm from the corner of the wall.

Attention: The described technology for installing beacons allows you to make the walls absolutely even, with an error of about 0.5 cm, which meets international standards.

Stucco preparation

Basically, such mixtures are made dry and packaged in bags weighing 30 kg or 50.

- So that the mixture can be applied to the surface, it must be diluted with water and mixed well, until a homogeneous mass is obtained, with a density resembling sour cream.

- To do this, take a plastic bucket with a capacity of 10-15 liters and fill it with water in 1/3 of the container.

- After that, a dry mixture is added to the water and thoroughly mixed with an electric drill with a nozzle. There should be no lumps in the finished mixture, otherwise it will be difficult to work with it. After this, the mixture is allowed to stand for 10 minutes.

Attention: For kneading it is better to use a drill with a nozzle, then your mass will turn out to be homogeneous and this process will not take much time.

Plastering

Plaster mortar applied to a clean, strong surface, using a wide spatula, from bottom to top. If you have certain skills, then you can throw it on the walls, especially if you need to apply a substantial layer.

- In one run, mixed plaster fills the space between the beacons. In this case, it is advisable to use the entire solution immediately, after which, as a rule, or with an even rail, resting against the beacons, the solution is pulled from the bottom up, while simultaneously moving left and right. Excess plaster is raked by the rule, leaving behind a perfectly smooth surface. Excessive plaster can throw gaps between the beacons.

- After filling one span between the lighthouses, they move on to another and so on until the wall is completely plastered.

- Rothband plaster is very plastic, so you need to make sure that it does not float under its own weight. This may be the case if there is a substantial layer. Noticing that the plaster began to float, you need to return to its original place and tighten it with the rule.

- After 40-60 minutes, you can begin to smooth the surface. The fact is that in the process of “tightening” small flaws are possible, which should be smoothed out. To do this, plaster mortar is mixed again and using a trowel or putty knife, this mortar is applied to the surface that has not yet been dried and smoothed.

Attention: You should always remember that subsequent work can only be done after the plaster layer has completely dried. With a layer thickness of about 2 cm, the “rotband” plaster will take about 6-7 days to fully dry.

Additional operations

If the walls are well smoothed, then you can glue dark but dense wallpapers on them. When sticking thin or light wallpaper, it is possible to see through the base of the wall, which is extremely undesirable.Many people wonder if it is possible to plaster a rotband in the bathroom and the answer will be yes.

Attention: In order not to risk it and bring the walls to their logical conclusion, 2 layers of finishing putty should be applied over the plaster layer and high-quality polishing should be done.

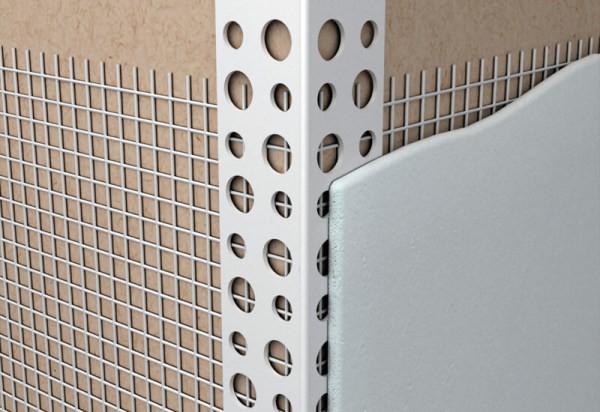

In any building, you can find both internal and external corners. If there are no problems with internal corners, then things are somewhat different with external corners, especially if they are in an area of heavy traffic. Such corners need protection.

So:

- This can be done if metal corners are installed on the outer corners, in the process of puttying. If the corners are correctly installed, then they will serve not only as protection, but also as peculiar beacons that will simplify the process of forming the outer corner. To install them correctly, you can use the same technology as when installing beacons.

- If it is planned to lay ceramic tiles on a plastered surface (see Facing with ceramic tiles: work that everyone can handle), then carry out additional operations does not make sense. Tiles can be laid directly on the plastered surface.

What is a reinforcing mesh

If the walls are being prepared for painting, then it is advisable to lay fiberglass on them reinforcing mesh with cells 2x2 or 5x5 mm. It is laid on the base with putty. Then the plane will turn out to be of better quality and it will be much easier to glue wallpaper on the plaster of the rotband.

So:

- The advantage of the mesh is that it will not allow the surface to crack.

- In addition, during its installation, the walls are somewhat trimmed if there were serious flaws on them. Laying the reinforcing mesh on weak, uneven surfaces is especially relevant, as it makes the walls more durable.

- The mesh is stacked from top to bottom, with an overlap of about 10 mm. It must be superimposed on all installed corners with an overlap of 10-15 mm, which eliminates the likelihood of cracks at the border of various materials.

- Reinforcing mesh can be installed on PVA glue. For this, PVA glue is diluted with water in a ratio of 1: 4, after which this solution covers the working surface with a roller having a long pile. The mesh is laid down and pressed against the wall with a wide spatula. In the process of grinding, excess glue is removed, and the surface is finally rolled with a dry roller.

- After complete drying, 2 layers of finishing putty are applied to the surface, after which it is allowed to dry. After that, the surface is carefully ground with a fine emery cloth and primed with a deeply penetrating primer.

- After such thorough preparation, the surface is ready to be painted with any paint, to apply Venetian plaster to such a surface, to glue any type of wallpaper or to wall the surface with any decorative materials.

Conclusion

In conclusion, it is worth dispelling the myth that the “rotband” plaster at a cost corresponds to a cement-sand mortar of its own production. The fact is that this is far from being the case and ready-mixed stucco mixes are much more expensive than cement-sand or lime-sand stucco mortars.

“Rotband” plaster can be afforded by people who have enough funds to purchase such a quantity of ready-made mixtures. Even the purchase of the cheapest putty mixtures, with a coating thickness of up to 5 mm, for finishing the whole house, flies a pretty penny, and if the coating layer reaches 2 cm, it is difficult to calculate how much such a plaster will cost, especially since on top have to go putty. The price of this material is quite high.