Fiberglass plaster mesh - types and scope

At the final stage of construction, finishing work is carried out. Plastering, painting and other operations are designed not only to decorate the building inside and out, but also to protect and strengthen the main building structures.

The glass-cloth plaster mesh used in these processes allows solving such problems as efficiently as possible.

The content of the article

When to use a mesh

Qualitatively finished walls and ceilings should be strong, smooth, without visible seams and joints. This can be achieved using plaster and putty (see How to putty walls in different versions) Such a coating will be as reliable as possible if reinforced with a fiberglass mesh.

Definition A fiberglass mesh is a woven fabric obtained by weaving fiberglass yarns that form many square or rectangular cells. The polymer coating and heat treatment ensure its stability and resistance to high tensile loads.

Material properties

Fiberglass plaster mesh due to its composition and special processing has unique performance properties.

It:

- Resistant to aggressive environments, including alkaline, therefore, it is well combined with mineral plasters that have an alkaline environment;

- Able to withstand severe loads;

- Provides shockproof surfaces, increases their strength and mechanical characteristics;

- It adheres well to putty and plaster;

- Protects the coating from cracking.

For reference. All the described properties directly depend on the density of the grid. This parameter is determined by the ratio of the weight of the material in grams to one square meter of its area. The higher the density, the higher the resistance of the mesh to various influences.

Purpose and scope

If you are going to do the repair yourself, you need to know in which cases it is advisable to use such a grid. Its main purpose is to strengthen the coating created by the mortar, improve its adhesion to the base.

Here is a detailed list of works where the fiberglass mesh plaster is used:

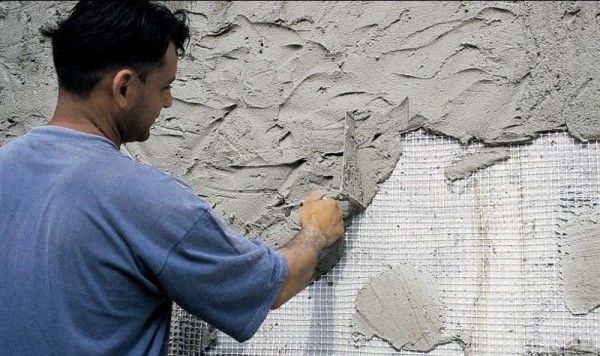

- Reinforcing plaster walls, including facades and socles (see Plaster plinth as a way to protect, strengthen and decorate);

- Reinforcement when leveling walls and ceilings with putty (see How to putty the ceiling - technological features of the process);

- Reinforcement of surfaces subject to cracking or already having cracks, before sticker wallpaper or painting;

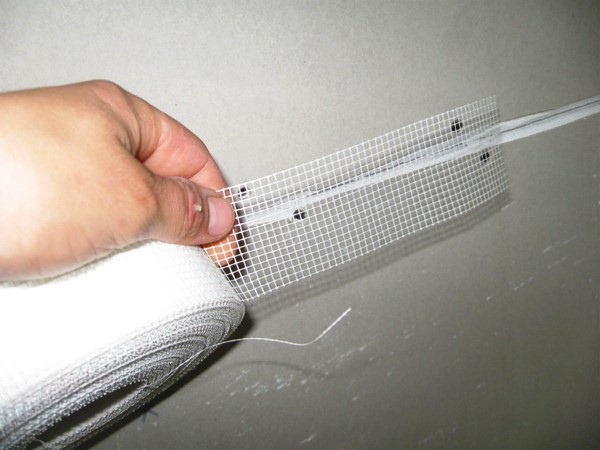

- Reinforcement of joints between sheet materials before their alignment;

- Reinforcement of leveling mixtures when filling floors;

- Waterproofing reinforcement;

- Improving the ability of surfaces to resist shocks and other mechanical stresses.

As you can see, the material is universal and allows you to improve the quality of any finishing processes, from rough alignment to painting work. Its price is low, and the effectiveness of the application deserves attention.

For each type of work, it is necessary to select a specific type of grid, focusing on its density, thickness and cell size.

Types of fiberglass

There is one rule: the thinner the applied layer, the less thin and dense the mesh should be, since it must completely hide under the coating. Each type of work has its own special type of material.

| View | Density g / m2 | Cell size mm | Application |

| Paint net | up to 50 | 2x2 | For interior work in buildings not subject to shrinkage: reinforcing wall and ceiling coatings, joints between floor slabs, interfacing window and door frames with walls. |

| Interior plaster grid fiberglass | 60-70 | 5x5 | For internal and external works when puttying and waterproofing surfaces, reinforcing substrates with increased density, repairing cracked plaster or putty. |

| Fiberglass reinforcement mesh | 100-115 | 10x10 | For the reinforcement of cement mortars used for screed or underfloor heating, the manufacture of borders, steps, paths and other structures experiencing increased load. |

| Universal fiberglass plaster mesh | 120-130 | 5x5 | Material of increased strength for strengthening thin-layer plasters of external and internal walls. |

| Facade mesh fiberglass plaster | 145-160 | 5x5 | For reinforcing plaster facades and systems of external insulation, strengthening places of abutment to the walls of window and door frames, protecting surfaces from the appearance and spread of cracks during outdoor work. |

| Reinforced mesh | 270-340 | 5x5 | For the reinforcement of plinths and other structures subject to heavy loads, as well as for the installation of bases for facing ceramic tiles. |

The quality of building nets is determined, first of all, by their ability to withstand the effects of an alkaline environment, which is available in finishing solutions, while maintaining their strength characteristics.

Note. The difference between the tensile strength of the mesh in the initial state and after 28 days of exposure in an alkaline solution should be no more than 50 percent.

On sale you can find materials in different colors. They depend on the type of polyacrylate dispersion, which the mesh is impregnated to give it alkali resistance.

Application features

There is a standard instruction that regulates the technology of mounting the grid.

Its main points are as follows:

- Installation of the material should be carried out with an overlap of at least 10 cm. Do not lay the mesh end-to-end or make incisions on it;

- The canvas should be recessed into the thickness of the plaster and be approximately in the middle of the layer;

- Fastening depending on the purpose of the material can be done in different ways: by gluing on the draft layer, followed by applying a covering, recessing in a fresh solution during application, fastening with dowels with wide caps.

Tip. When choosing a grid, pay attention to the correct geometric dimensions of the canvas and cells, the absence of elongated and bubbling areas. If the roll, when unfolding, has distortions, it will not be possible to lay the material on the surface qualitatively.

Conclusion

The requirements for reliability, durability and quality of construction work are constantly growing. Nobody wants to, after spending an impressive amount on the construction and decoration of the house, after a short time to discover cracks in the facade or plaster crumbling from the walls.

The use of fiberglass virtually eliminates the risk of such problems. You can learn more about this material and learn the rules for its use by watching the video in this article.