Aluminum cladding: wall panel accessories

Panel wall decoration is an integral part of the modern design of interiors and facades - and not just office ones. Each self-respecting manufacturer offers the consumer not only the material itself, but also everything necessary for its installation: sub-structure elements, starting strips, fasteners.

There are four ways to install wall panels, and two of them also require aluminum profiles for wall cladding. You will learn about the types and purpose of these accessories from the video on the topic: “Facing with an aluminum profile”, offered to readers of our site in this article.

The content of the article

What is a profile for?

Decorative and decorative panels are made of both wood and its derivatives, as well as gypsum, polymers, various composites. Wood and wood-polymer cladding are most often mounted in the tongue-and-groove way, polymer and bamboo panels are glued.

As for laminated gypsum panels of the Viprok, Giplast, MDF type or Rigidur glass-magnesite plates, an aluminum facing profile is required for their installation. Its use allows not only to simplify the installation and dismantling of cladding elements, but also, moving away from the monotony of the surface, to achieve a certain aesthetics in the interior.

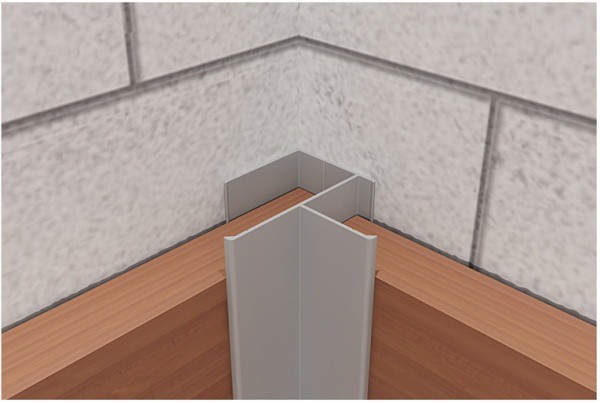

In addition, the aluminum profile for wall cladding protects joints, ends and corners from mechanical damage. Moreover, there is a profile designed to fix the panels, and there are purely decorative accessories that are used exclusively for camouflage extreme and docking areas.

Thanks to them, the lined surface has a finished look, and looks like a thoughtful composition.

Profile Views

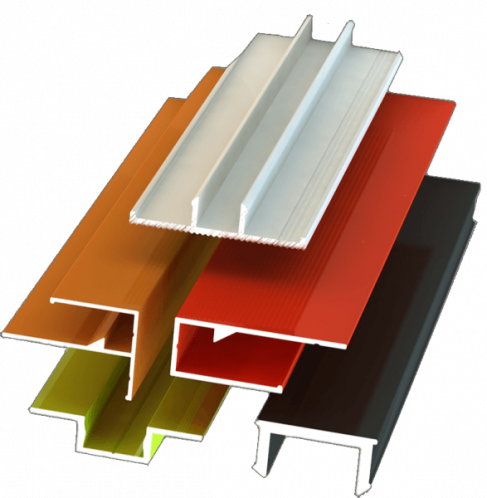

Profiles, as such, can be made not only of aluminum, but also of galvanized, and even stainless steel - it all depends on the manufacturer, and, of course, the type of panels. Their price depends on the raw materials used in production, as well as the option of front decoration of products.

And yet, the aluminum cladding profile is used most often: it is both cheaper in cost and lighter in weight. Therefore, our story is about him.

Types of profiles:

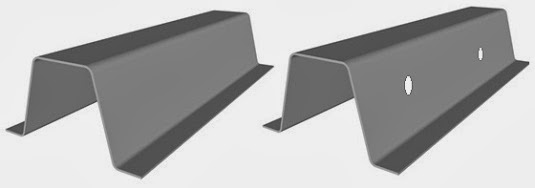

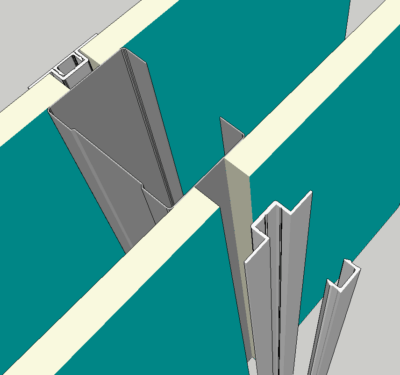

| Appearance and profile name | Profile Assignment |

| A profile with a cross section in the form of the Greek letter “omega” is a carrier. It is used for installation of partitions made of gypsum vinyl or laminated MDF, as well as for joining panels with wall cladding. | |

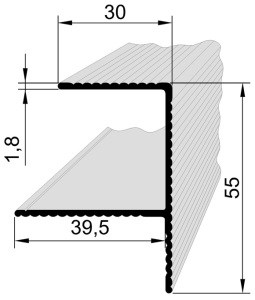

| This type of profile is used to frame the corner zones for wall cladding. | |

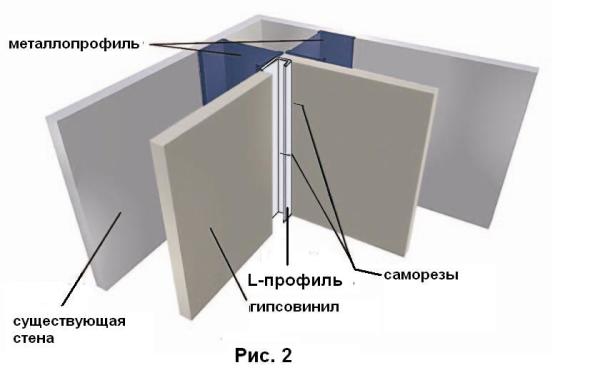

| There is also a L-shaped profile. It is used mainly for decorating internal corners, as well as for decorating the joints of walls with ceilings and floors. |

Options for installing panels using a profile

For panel mounting small format, and a thickness not exceeding 12 cm, often use a method called "groove-groove". It is ideally suited for those types of panels that have end recesses around the perimeter.

The essence of the method is that one shelf of the U-shaped profile is inserted into the grooves, and the other shelf is fixed to the base.

So:

- With this installation option, the surface is smooth, and the joints between the cladding elements are practically not visible.This type of profile usually comes with panels that are designed specifically for such a connection. But it is worth saying that for money it comes out somewhat more expensive, and therefore it is used less often.

- A more popular mounting option is the panel-to-groove method. Its cardinal difference is the fact that it is not the profile that goes into the recess at the edge of the panel, but rather that the end of the panel is inserted into the groove of the profile.

In this case, the surface of the cladding is as if “plotted” by strips into squares or rectangles. Maybe not everyone likes this kind of graphics, but it can be attributed to the advantages rather than the design flaws. Take a look at the photo above and judge for yourself.

Some subtleties of installation

All types of sheet panels, whether GVL with vinyl or plastic coating, or laminated MDF, are installed on the frame, by analogy with drywall. That is, a crate is being constructed, consisting of vertical struts and transverse belts mounted from the profile ППН28 * 27 and ПС60 * 28.

So:

- If the walls are even, the supporting profile can be mounted behind a shelf, directly to their surface. Otherwise, to level the plane you have to use direct suspensions. The pitch between the uprights usually does not exceed 1.2 m, plus the width of the omega profile, usually corresponding to 12 mm.

- The distance between the horizontal elements of the crate should be such that the panel can be fixed in three places - in the corners and in the middle. When mounting small-format panels, the step of the transverse belts can simply correspond to the width of the product. In any case, when buying panels, you will be offered installation instructions, and you need to be guided by the manufacturer's recommendations.

- When the crate is installed, you can proceed with the installation of start and finish strips. The L-profile copes with this task perfectly, but if at the end of the lining it is planned to install patch skirtings, both floor and ceiling, you do not need to install a corner in these places.

- It is worth saying that the installation of decorative panels should be carried out only after the final floor covering has been completed. If the L-profile will still be used, then between it and the floor there should be a layer of porous rubber, or a strip of cork substrate.

The panels are hung on the frame, at a distance corresponding to the width of the back of the omega profile, plus a small gap (3-4 mm) for linear expansion. In the corner, the F-profile is not mounted closely, but at a distance of 2-2.5 mm - so that the panel can be brought into the remaining space.

The joints between the cladding elements, formed due to the omega-profile, are closed with plugs, and this is the final stage of work.