Gypsum wall and ceiling cladding

Everyone knows about the wonderful properties of gypsum, because it is not for nothing that this material has been used for centuries in interior decoration. Over time, only new finishing materials based on it appear.

Thus, gypsum cladding in one form or another is almost always present in the room. These are plaster mixes used for leveling surfaces; and stucco molding; and ceiling tiles; and gypsum board lining.

These and other gypsum materials will be discussed in this article.

The content of the article

Plaster products for cladding

This natural material is so popular because it is absolutely safe for humans, has no smell, and is able to regulate the humidity level in the room, taking its excess. Gypsum has a snow-white color and is easily formed, which is the most valuable quality for the production of curly products.

So:

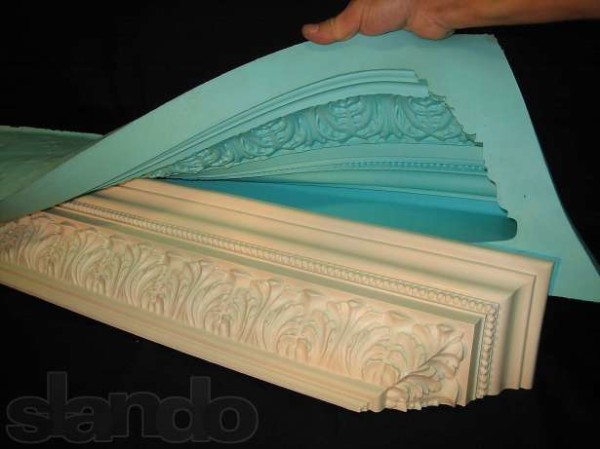

- Stucco elements for decorating the ceiling, walls, columns (seeColumn decoration: doing it right); gypsum cornices; tiles, and even panels with 3D effect are produced, of course, and in the factory. But, having a silicone form, all this is easy to do at home, you only need instructions, and even better - a video.

- The price of a product made on its own, of course, will be less than a similar product purchased in a store. Savings are especially noticeable when a large amount of work is ahead.

- With strict adherence to the technology, you will be pleased not only with the cost, but also with the quality of the gypsum products, which will turn out to be no worse than the factory. If you can make high-quality stucco molding with your own hands (seeStucco decoration or frozen gypsum music), then the gypsum wall or ceiling cladding will not be difficult for you.

- All molded products differ only in configuration and purpose, and are produced using the same technology. We outline it briefly. Plaster dough for stucco molding production consists of only two components: gypsum and water, and you need to mix it correctly.

- First, the required amount of water is measured, which is poured into the mold, and then poured into a container for mixing the solution. Gypsum is sieved through a sieve, and added in small portions to the water, with constant stirring.

- The solution should not be too thick, have the consistency of liquid sour cream. After ten minutes, it is poured into the mold for three quarters, or, as it is also called, a compound.

In this case, the form must be in a rigid box made of wood or plastic - this will protect the product from accidental damage. - Shake the mold after pouring so that the mixture is compacted and air bubbles come out of it to the surface. In factory shops and workshops, special vibration tables are used for this purpose.

After compaction, the surface of the gypsum is carefully smoothed with a spatula.

- If the product is large, for example: a panel or ceiling cornice - to give strength, it is reinforced by laying wire, tow, or thick twine in the thickness of the solution. A fiberglass mesh will do just fine with this task.

- To set gypsum, it takes no more than half an hour, after which the products are carefully removed from the compound and laid out on a flat surface until they finally harden.

- A mold for pouring gypsum mortar can be purchased ready-made, or you can do it yourself by buying liquid silicone. Only in this case, you will need samples of products that you want to make.

- By the same analogy, they also make gypsum facing stone. There are a lot of articles on our website that tell about how to artificially imitate natural stone.

Typically, cement, quartz sand, or stone chips are present in mixtures for its production.

- The weight of such a simulation is, of course, less than that of natural stone similar size. But gypsum facing brick is even lighter than artificial stone, and much more.

The difference in weight is due to the fact that, firstly, gypsum is lighter than cement, and secondly, lighter expanded clay chips are used as filler. - Pigment can be added to the solution from which the gypsum facing stone will be made. Inorganic dyes are not afraid of ultraviolet radiation, so the products will retain their original color under any operating conditions.

- Gypsum cladding stones in appearance are practically indistinguishable from natural sandstone or dolomite. Especially if their configuration imitates characteristic chips on the surface of natural stone.

This makes it possible to replace expensive natural material in interior design with a more affordable analogue.

- There are no problems with the decorative properties of gypsum products, but this material does not like temperature changes. To improve its characteristics, special additives can be introduced into the composition of the solution for the manufacture of stone.

- For example, a gypsum fireplace lining must withstand high temperatures. Chemical fibers are added to the mixture for the production of such a stone, preventing the appearance of cracks on its surface.

In the picture above you can see a wonderful interior where the fireplace wall is decorated with plaster stone.

- Facing gypsum brick is used not only in interior design, but also for decorating facades. In its production, polymer and hydrophobic additives are used, which increase the strength and durability of products, and reduce the coefficient of water absorption.

Both the stucco molding and the facing stone are mounted on special gypsum glue. There are no particular difficulties in this work if the surface is relatively flat and treated with a primer.

Plaster sheet material

For decoration, sheet gypsum material is also used. What are cladding sheets?

This is called dry plaster, or gypsum plasterboard (GKL). It is also briefly called hyperpro.

So:

- Drywall sheet is a product from a hardened mixture of gypsum and technical foam filler, glued with cardboard on both sides. Cardboard plays the role of a reinforcing shell for the core of gypsum, increases its strength.

- There are several types of drywall, which include various additives to improve its characteristics.

With the help of these additives, the moisture resistance of products that are labeled (GKLV) is increased. There are fire-resistant options (GKLO), as well as combining both those and other properties (GKLVO). - Other types of drywall are also produced: acoustic, windproof, reinforced, designer. Each of them has its own additional properties, and purpose.

These types of giprock are used for sheathing surfaces and creating decorative structures: partitions, as in the photo below, suspended ceilings, curved shapes.

- There is another type of gypsum cladding sheet - this is gypsum fiberboard (gypsum fiber sheet). This material, like giprok, is made of gypsum, but has a uniform structure, without a combustible cardboard cover.

- Gypsum dough is reinforced by adding dissolved pulp to it.The density of such a sheet, and, accordingly, the strength, is much higher than that of GCR.

Thanks to this, not only wall cladding with gypsum-fiber sheet, or the creation of a false ceiling is possible.

- GVL is used for the installation of working structures designed for a specific load. For example, you can make a niche in a room that can support the weight of furniture or household appliances.

- All gypsum fiber sheets are frostproof and fireproof. There are also moisture resistant options (GVLV). These properties allow you to use them for cladding unheated rooms.

It is also important that the soundproofing properties of GVL are 40% higher than that of a gyro. And this means that wall cladding with gypsum-fiber sheets is the best choice for many institutions: educational, sanatorium-resort, recording studios, reading rooms.

However, the walls of the bedroom, lined with GVL, will also please, saving us from unnecessary noise, and making a relaxing night's rest.