Facing with profiled sheet: building exterior

The facade with a professional sheet lining, the price of which is much more affordable than many materials used today, has long ceased to be the prerogative of only industrial and administrative buildings, roofing. Beautiful relief, color assortment, and ease of installation contributed to the fact that profiled flooring has become a material popular in the decoration of the exterior walls of low-rise residential buildings.

In our article, instructions will be given on the choice of material, as well as a video on the topic: “Technology for facing with a professional sheet”.

The content of the article

The choice of wall cladding

The corrugated board is made of galvanized steel sheet, which is shaped into a particular shape by cold pressing. At the same time, it acquires not only an interesting appearance, but also a certain strength.

The material has a small weight, which allows to minimize the load on the structural elements of the building:

- According to its purpose, the profiled sheet is classified into roofing, bearing and wall. Roofing sheets most often have a protective polymer coating, and in appearance resemble tiles.

- The supporting professional sheet is used constructively. It has the greatest strength, and can withstand even the weight of a person.

The ability to resist such loads is provided by stiffening ribs formed by the greatest depth of bending of the relief. - The profile of the wall sheets is not so high, it can be painted, and even made not of steel, but of even lighter aluminum or copper. Since the topic of our article is technology wall cladding profiled sheet, we will focus on the wall material, and universal options that can be used both for walls and for roofing.

- You can distinguish the purpose of the sheet by its marking, which has an alphanumeric meaning. The letters at the beginning of the marking determine the purpose, and the numbers reflect the wave height in millimeters.

The letters (A) and (B) at the end of the line indicate on which side: front or back, a decorative coating is applied.

The table shows several basic options used for cladding houses.

| Mark | Leaf relief | Main characteristics |

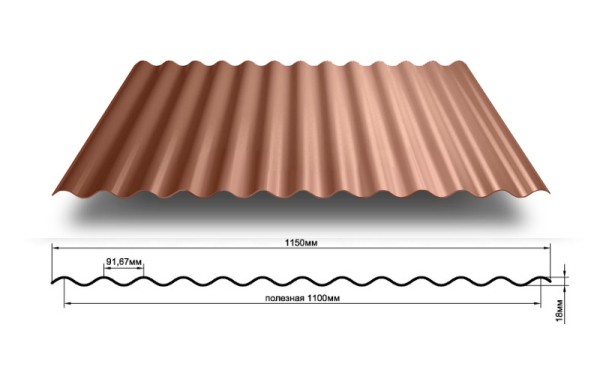

| C8 | Zinc or polymer coated wall material with a wide range of colors. Attractive appearance and low price contribute to its popularity among the population. In cross section, the relief has a trapezoidal shape, where the height of the corrugation is 8 mm and the width is 51.5 mm. A sheet with a working width of 1.15m holds 10 bends. | |

| C21 (B) | Corrugated wall, with a trapezoidal relief 21 mm high. It is used not only for wall cladding, but also as a roofing material. It is applied at factory assembly of composite wall panels. Eight thickness variations are produced, from 0.4 to 0.8 mm. The width of the sheet is 1 m, the length can be from 1 to 12 m. | |

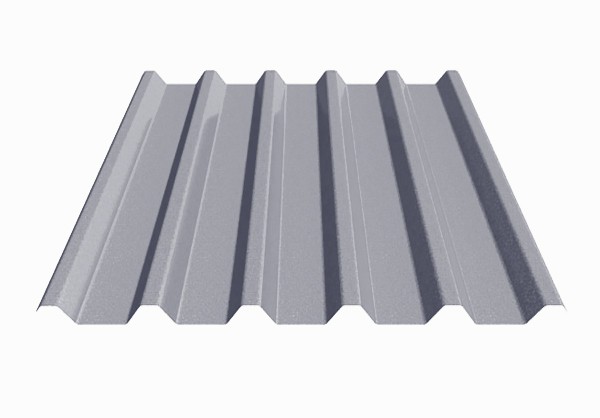

| C44 (B) | Wall profiled sheet, has a corrugation in the form of a trapezoid, 44 mm high, the pitch between bends is 35 mm. The appearance of the sheet is formed due to the width of the ribs 100 mm. The minimum thickness is 0.5 mm, the length of the profile is 14.5 m. It can be used in any structures except for supporting ones, as it does not have additional stiffening ribs. Often has a double-sided color. As a polymer coating, polyester, PVC plastisol, and pural are used in the production. | |

| MP18 (V) | This type refers to universal options, has high performance characteristics.It is produced both from galvanized steel and from thin sheets with a paint and varnish coating. The thickness of the sheet varies between 0.5-0.8 mm. Width is standard, 1150 mm. High strength is ensured by a sinusoidal shape of the relief, with a corrugation height of 18 mm. Available in a wide range of colors, with a polyester coating. In the photo at the beginning of the article, a wonderful example facade cladding professional flooring MP18. | |

| MP20 (A; B) | Universal profile with double-sided polymer coating. When roofing, the manufacturer recommends laying it with a narrow edge up (side B), whereas for wall cladding, the front side is side “A”. Although, the layout of the sheets is not of fundamental importance for wall decoration - this is important only for the roof. It has a trapezoidal profile with a wide edge (67.5 mm). The height of the relief is 20 mm, the pitch between the corrugations is 35 mm. | |

| MP35 (A) | Profiled flooring for universal use. It is used not only for decoration and roofing, but also structurally. The width of the sheet is 1035 mm, thickness from 0.5-0.9 mm. The height of the corrugation is 35 mm, the width of its ribs is 119 mm. The step between the bends is 40 mm. The sheet has additional stiffening ribs, which allows the material to withstand significant loads. It makes it possible to clad a roof or wall with a complex configuration. It is practically not deformed, and therefore can be reused after dismantling. | |

| MP40 (A) | Universal option. The corrugation of the sheet is round, which significantly improves the decorativeness of the finished surface. The size of the side frames is increased to 55 mm - this increases the reliability of the fasteners. The overlap ensures tight joints. The length of the sheets, with a width of 1m, varies up to 12m. The thickness of the metal is from 0.5 to 0.7 mm. The height of the relief is 40 mm. The sheet can be painted on both sides, or have a one-sided polymer coating. |

We hope that the information about the material that you could get from this table is enough to select the appropriate option. And how is the walls lined with profiled sheets - the finishing technology according to the insulated system ventilated facade - You will learn from the next chapter.

Professional sheet in the arrangement of the facade

In connection with the constant rise in the price of fuel, and toughening of the standards related to electricity consumption, the issue of building insulation is more relevant today than ever. Almost all modern technologies are aimed at developing materials to achieve the maximum effect.

In order not to reduce the useful area of the house, most of their owners prefer to perform insulation from the outside. Although, in the northern regions, it can be bilateral.

So:

- That is why, the most popular materials are currently used, the installation technology of which includes the insulation process. Profiled flooring is one such material. Moreover, the technology of its installation is quite simple, which allows any owner to venerate the house with their own hands.

- The profiled sheet is mounted on a metal frame, and for its arrangement you will need three types of profiles. The supporting profile has a Z-shaped cross-section, this shape allows you to ensure rigidity. As a guide, a profile with a T-section is used.

The third type of profile has an L-shape, it is simply called a corner - it is on it that the sheets are fastened, and docking to window and door openings is also performed. - As fasteners for corrugated board, self-tapping screws with press washers or decorative bolts are used. To ensure the necessary indentation from the surface of the walls, KKU brackets are needed.

The indent should be such that after laying the insulation, a gap of at least 3 mm remains - it ensures the proper ventilation of the entire structure and prevents the formation of condensation inside it. Brackets are fixed with dowels.

- In principle, the installation of corrugated board can also be done on a wooden crate, just keep in mind that its service life is much shorter than that of a metal sheet: damp, rodents - special antiseptics do not give one hundred percent protection. Therefore, it is not worth saving on the frame if it is not some kind of temporary building.

- It is very important that plinth trim professional sheet, on the lower perimeter rested on a flat surface. Therefore, if there is simply compacted soil around the foundation, it is advisable to make a blind area: from asphalt, concrete, paving slabs or stone - that's how you like it. If the house has a protruding foundation, then the wall lining will rest against it.

- With the help of the level, just above the blind area, or the protruding part of the foundation, a horizontal line is drawn on the wall - around the entire perimeter of the house. Use a dye cord for this. A starting profile will be mounted along this line, on which the first row of insulation is supported.

- Before installing the frame, you need to take care of the waterproofing of the walls - this can be either hydrophobic impregnation or a roll membrane. To fix the profiles, brackets are installed. The supporting profile is mounted horizontally, in increments equal to the width of the insulating material.

- Cross, L-shaped profiles are installed vertically, in increments of 50 cm. Almost all sheets of corrugated board have a working width of 1 meter. Therefore, with a step of half a meter, it will be convenient to fix them both along the edges and in the center.

The insulation is laid in the cells of the crate, fixed with plate-shaped dowels, or by glue. Then, if there is no factory foil layer on it, a windproof membrane is mounted on top.

- Further, it remains only to hang sheets on the frame. For finishing corner areas, manufacturers offer special additional elements, with a bend of 90 degrees. Laying the profiled sheet is overlapped. Before fastening, a hole of a slightly smaller diameter than the size of the screw should be drilled at the desired point.

- Sheets are cut using a hand circular saw or a jigsaw. Scissors for metal can be used only when cutting across the corrugation. A grinder for this purpose is not suitable at all, since it damages the polymer coating. Of the hand tools, you can use a hacksaw, but the performance is greatly reduced.

If everything is done correctly, the facade of the house will surely please its inhabitants, as well as passers-by, with its interesting appearance. Moreover, facing with a professional sheet perfectly combines with other types of finishing materials and stained-glass windows. A wide range of shades of polymer coatings makes it possible to create a design for almost every taste.

Due to the fashion for the “loft” style, cladding with corrugated board becomes just a godsend for the designer. Together with a large single-volume room, a harmonious combination of internal and external decoration of the building is created.