Paneling slopes: the final stage of repair in the house

The process of replacing window blocks and doors - the procedure for the inhabitants of the house is quite painful. Not only is it full of dust and construction debris, it is also necessary to restore broken slopes.

If repairs are made in the entire apartment and the walls are to be leveled, the slopes can be repaired in the same way. And if you need to do everything quickly and as cleanly as possible?

In this case, facing the slopes with plastic panels will help. Do it yourself, you will learn the video presented by us, as well as the instructions in this article.

The content of the article

Window slopes

Starting to finish the slopes, their surface must be thoroughly cleaned of dust and the remnants of the old plaster, and then impregnated with a biocidal primer - even if this is not a putty leveling (see. Alignment putty in accordance with all the rules), and facing the slopes with PVC panels.

This will prevent the formation of mold under the skin. This is especially true for exterior windows and doors, where condensation may occur as a result of temperature differences inside and outside the room.

Cladding panels

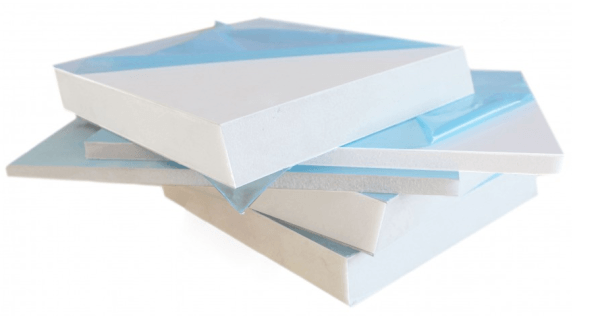

In principle, the slopes can be faced with MDF, laminate, and natural wood (see Finishing window slopes in different ways), but this is done mainly when all the walls of the room are decorated with the same material. In most cases, for this purpose they use: either a wall paper-laminated plastic or a sandwich panel, which you see in the photo below.

So:

- It makes sense to use decorative plastic panels for facing slopes when they also wall cladding - then it looks harmonious. In other cases, it is better to take white sandwich panels, especially since the price for a sheet of 3000 * 1500 mm is lower than for a PVC panel of the same area.

- They differ not only in appearance, but also in structure. If voids are visible on the slice inside the wall plastic, and the panel is slightly springy under pressure, the sandwich panel is a three-layer composite: two thin layers of plastic, pressed with polymer foam.

Such panels are more durable and have high thermal insulation properties. For the decoration of slopes, sheets of thickness 8-10 mm are usually used.

Slope sheathing

Both those and other panels are mounted similarly. For work you will need a level, mounting foam, a screwdriver and a cutting tool. Facing slopes begin not earlier than a day after the installation of the blocks, so that the foam assembly hardens well.

- The surface of the slopes is very uneven, which creates certain problems when facing. The installer's task is, first of all, to align them. Therefore, the work begins with a level reconciliation of their surface, as well as the cleaning of excess foam that protrudes beyond the junction of the window and the opening.

- Then, to cut the panels and the plastic profile to the desired length, it is necessary to measure the width and height of the slopes. By the way, in order to face the slope, you need to purchase two types of profiles: U-shaped start, and F-shaped finish.

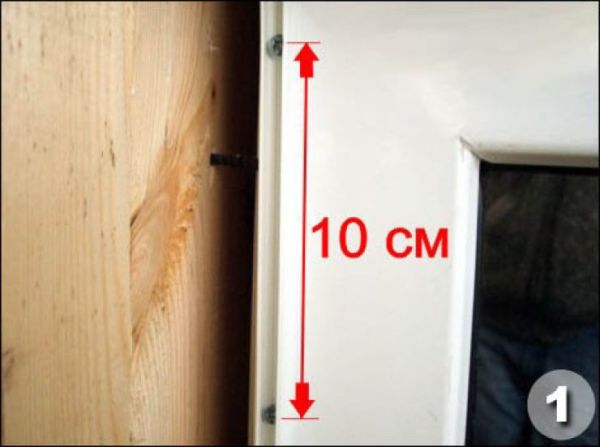

- The start profile is attached directly to the window frame, and 8.5 mm long screws are used for this. They are screwed at a distance of 10-15 cm from each other, starting from the edge of the frame. The distance from the profile to the wall depends on the degree of unevenness of the slope. It should be such that the position of the cladding element does not deviate due to protruding sections.

- The space between the profile and the base surface is filled with foam. Further, according to previously taken sizes, the panels are cut - and this is best done with an electric jigsaw. The protective film from the panels is removed after cutting, before installing the part in its rightful place.

- Before installing the part, it must be tried on - this will make it possible to verify the correctness of the cut. First, the side elements are placed in the grooves of the start profile, and their ends are closed with the finish profile, and then they begin to install the upper horizontal panel.

- All joints between the parts and the profile are coated with white sealant, and the space formed between the cladding and the wall is foamed. For more reliable fixation of the structure, transverse strips of masking tape are glued along the finish profile.

- They are removed in a day, when both the foam and the sealant are completely dry. In the same way, slopes can also be faced with drywall. The only difference is that instead of foam, gypsum glue is used here, although a wooden crate can be made if desired.

Despite the fact that the drywall surface still has to be puttied and painted, this slope looks much better. Moreover, plastic under the influence of ultraviolet light turns yellow over the years, and drywall can always be refreshed with the help of painting.

Slopes of an entrance door from a laminate

Interior door slopes (see DIY door slopes) are usually finished in the same way as walls: they are plastered, sheathed with drywall, plastic or wood. There are special sloping slats that can be perfectly matched to the color of the door, but this option is only good when the slope is narrow.

- But at the entrance - especially when two doors are installed, and you need to veneer the space between them, it is hardly possible to come up with something better than an ordinary floor laminate. It is very convenient that the size of the panels can be adjusted to the slope so that the strips do not have to be joined in width. Although, there are very deep slopes - then it is better to take a sheet rather than a floor laminate.

This type of decoration is also good because for the convenience of the inhabitants of the house, spotlights can be built into the casing.

Laminate mounting principle

As in the case of the window, the slope is uneven. But the door is the door, here the slope can touch both when walking, and when moving furniture.

No plastic profile can withstand such loads. Therefore, the alignment of the plane of the slope is due to the bars mounted to the base.

So:

- Usually start from the threshold. Having previously measured the width of the opening, the panel is cut and tried on. In order to have where to fix the panel, protruding choppers are hammered under the door frame, using pieces of plywood or laminate trim for this purpose.

- Around the choppers, and along the horizontal contour of the frame, lay a strip of mounting foam. If the width of the slope exceeds the width of the laminate panel, then on the threshold they are joined using such a profile, which is shown in the picture. Until the foam has frozen, the threshold part is installed, crushed with something heavy, and then, to close the front end of the laminate, an aluminum nut is screwed.

- Next, proceed to install the upper cladding element. Details for the threshold are always cut from a solid panel, but for the top, in order to save material, you can use trim. Lock edges are cut from the panels, leaving only those that are needed to connect the pieces together.

- They cut the laminate with an electric jigsaw, and in order not to disturb the decorative layer, do it at an angle. Small scraps are not thrown away, but cut into small strips, which are then installed as temporary mounting spacers.

- Their position is verified so that the part resting on them is in a single horizontal plane. To struts held on the surface of the frame, they are pre-glued mounting tape. Then, a mounting foam is applied along the contour of the upper slope, and the cladding element is installed in its place.

- To prevent it from falling off under the weight of its own weight, mounting struts are also glued on the front side. Their task is to keep the part in the right position until the foam dries completely - then they are simply removed.

Lastly, side slopes are installed. Their installation is carried out similarly to the upper element, using mounting spacers.

If there is a desire to veneer window slopes with a laminate - there are no problems, everything is done in the same way.

And I always cut the laminate with a grinder. If you take a metal disc, the cut is very smooth.