Finishing slopes - many options

Everyone wants a beautiful and comfortable home. Proper and high-quality decoration allows you to create a wonderful atmosphere in the house, conducive to a good rest and good mood.

The content of the article

Slopes are an important element of decoration

Slopes are one of the elements of the house that can not only create a good mood, but also spoil it if improperly performed. Slopes are not just good to do, you need to choose the right elements slope finishes.

How many materials, so many mounting options

The list of materials used is quite diverse, it can be plastic and drywall and wood paneling and a lot of different material.

It is important to understand how diverse the material is and how diverse its installation is, and even when using the same material, various methods of fastening and installation can be applied.

For example, if you have wide internal slopes, finishing is done in one way, if narrow in another. In this article we will try to talk about some materials and how to install it.

We finish the slopes with plastic

Plastic slopes do-it-yourself completely affordable type of decoration. Let’s take it in order from where to start this work, how to continue and finish.

Surface preparation is an important step

First you need to prepare the surface of the slopes for the installation of PVC:

- If you have new windows, then most likely the gaps were foaming.

- Use a construction knife to cut off any excess foam.

- Clean the surface of the slopes of dust, dirt and foreign objects.

Start profile - what and how to do it right

When the surface is cleaned, you can proceed to the next step: mounting the start profile.

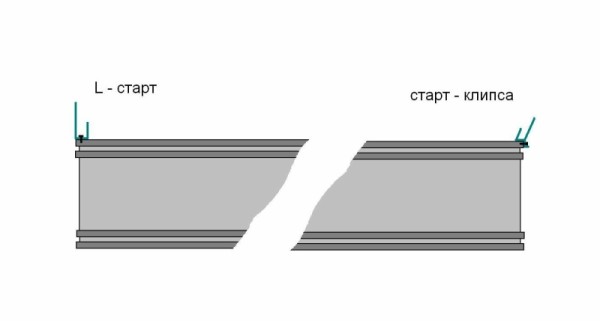

Our reference is a starting profile in the form of the letter P, which performs the function of docking a PVC panel on a slope with a window. For plastic windows, a special start profile is used: start - clip. Our advice is - if you do not have start - clips for plastic windows, use the universal start profile referred to as L - start.

Many may ask: how do these profiles differ from each other?

The fact is that the start - clip has a steeper angle of inclination than the L - start. Therefore, the start - clip is more convenient to use on windows with slopes with a large spread.

We repeat, although the L - start does not have such a U-turn, it can also be used, since the profile lends itself well to deformation.

Installation of the start profile

We continue the installation:

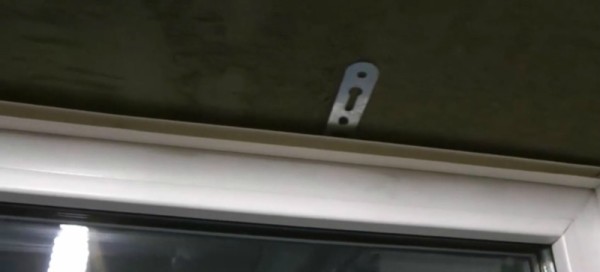

- Using construction tape, it is necessary to measure along the inner perimeter of the window profile.

- Next, measure the required length on the start profile, make a mark and cut it off.

- Fasteners are carried out along the very edge of the window profile. For fastening, it is necessary to use self-tapping screws with a drill. In this case, the pitch of the screws should be 150 - 200 mm.

Thus, the profile is fixed to the window. It is important to understand that it should be fixed only in places of future slopes.

In other words, on the right, left and above, below in the place of the windowsill, the profile does not need to be fixed.

We collect the crate

It was the turn to mount the crate. As a material for the crate, it is necessary to use a bar with a cross section of 20X40 mm.

Our advice is to use only well-dried wood.

Before installation, it is necessary to take a number of measures to protect wooden structures:

- Since the beam is mounted on the outside of the slope, we make the necessary measurements and cut the beam of the required size.

- Next, we cover the timber with a special protective composition that prevents rotting of the wood.

- When the composition is dry, the beam can be fixed in place.

- Depending on the material of the walls of the room, select the appropriate fasteners. If your walls are made of concrete or brick, use a dowel - nails for fastening.

The mounting pitch should vary between 350 - 400 mm. - Use the building level to control the position of the beam during installation.

Installation of PVC panels

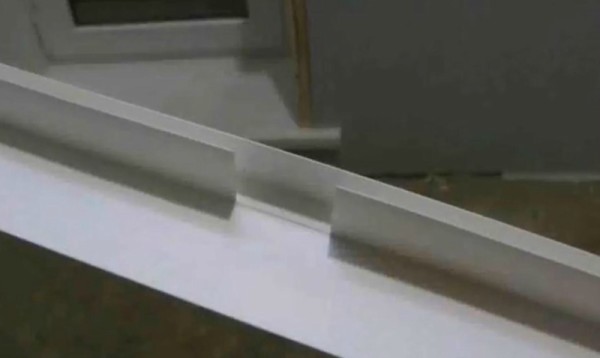

When the beam is fixed at the edges and top of the slope, it is time to fix the PVC panels. Begin from the top.

To do this, first take measurements on the slope. Cut the panel to your size.

Our advice is that it is very convenient to use a jigsaw for such work. If there is no jigsaw, you can use a hacksaw with small teeth. The most important thing in this work is to get completely even edges.

So:

- The finished top panel is inserted at one end into a pre-installed start profile.

- The other edge is attached with screws to the battens. In this case, the screw is screwed into the end of the panel at an angle of 45 degrees.

Thus, we will hide the head of the screw for further decoration.

- Just as we installed the top panel, we install two side panels.

- First, insert one end into the start profile, and screw the other end to the crate.

Platbands - a ready-made profile to help

Finishing the slopes with plastic do-it-yourself is not finished, we have no platbands:

- In the quality of platbands, you can use the F– PVC profile.

- The profile is measured along the outer window perimeter and cut off.

Important - in the places where the profile touches the head of the screws, it is necessary to make incisions in the internal partition of the profile. Unnecessary pieces are removed.

- Next, the F - profile is tightly inserted into the installed PVC panel. That's all, the installation is completed.

As you already understood, if you observe the correct dimensions and perform accurate, even cuts, you will get perfectly even slopes.

Stitching - finish line

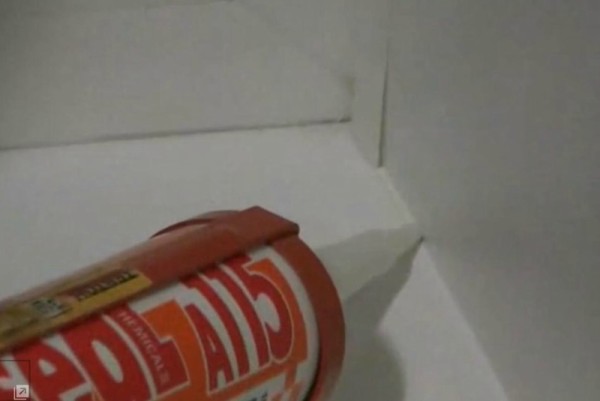

But in this case, there is no escape from the seams. It is time to do seams.

To prevent moisture from entering plastic slopes, the seams must be sealed. A white sealant or selikon is perfect for this.

- Apply sealant to the seams with a special gun.

- After the sealant is applied using a piece of plastic remaining from the scraps of the profile, remove its excess

Now everything is really, you got beautiful, smooth and beautiful window slopes.

We examined how to finish wall slopes with panels. But we have already said that there are many methods and materials, so at least one more should be considered.

Plasterboard slopes

Let's consider another option, namely how to finish the slopes with drywall. Suppose we have new windows installed, the room is built of brick.

Cooking groove - fastening

The first step is to make a groove for mounting the GKL panel. If in the first case we used a start profile to fasten the PVC panel, in this case we will do differently.

So:

- After the installation of windows is completed, the gap between the window and the walls is foamed.

- Using a carpentry knife, we cut the protruding foam flush. Thus, the foam area will be located at the same level with the window.

- Further along the entire perimeter of the window in the places of slopes, in the foam, we cut a groove with a depth of 10 - 15 mm.

- The groove is made so that the GCR panel can freely lie on the window frame. As for the width of the groove, I want to make a small addition.

The width of the groove should correspond to the thickness of the GCR used. We hope this is clear.

Production and installation of a slope

We measure the size of future slopes. According to them, we cut out the elements of the required size, the upper and two side ones, from the GKL sheet.

When attaching the PVC panel, we used a crate. In this case, the crate can also be used, but only if the size allows us to window opening.

Otherwise, the turn of the slopes will be either too small or performed in the opposite direction. We cannot allow this. Therefore, we will stick the slopes from the GCR.

To do this, get a special glue. It is in almost all stores.

Finishing the slopes with your own hands, and in this case, starts from above:

- The window opening must first be cleaned of dust and dirt and carefully primed with a special primer.

- On the finished slope element, apply glue with a spatula, the thickness of the glue layer should be so large that when installing the panel it could be well fixed to the outside of the window opening.

- Thus, glue is applied only from one edge of the panel, on the side not adjacent to the window.

- Insert the GCR panel into the prepared groove and until it is pressed with the adhesive side to the window opening.

- Now it is necessary to apply the foam from the inside to the place of contact of the gypsum board with the foam, into the groove.

Our reference - If you plan to insulate the slopes, now is the time to insert the insulation.

- Now the panel must be gently pressed to the slope so that the existing glue shrinks and begins to fill the gap. Do not press tight yet.

- Take the building level, controlling the position of the sheet of the future slope, begin to press the adhesive side.

- Thus, our panel is installed.

- To fix the GKL sheet until the glue sets, it is necessary to use additional supports. We will not consider them, everyone will be able to make them to their taste and according to their own capabilities.

After the glue has dried and the supports will be removed, you can further strengthen the sheet using dowels - nails. Two along the edge and one in the middle is enough.

The other sides are mounted similarly.

GKL installation on the slopes - option No. 2

But what if the windows are installed in such a way that the gap between the frame and the wall does not allow the GKL sheet to be inserted there? In other words, the windows are installed back to back.

In this case, the installation is performed as follows:

- In addition to glue and drywall, we need a CD profile or another PP (ceiling profile).

Since the dimensions do not allow us to perform a groove, instead of it we mount a PP profile:

- Cut it to the required size and fasten with the expansion bolt shield - nails.

- The most important thing in this case is the observance of the correct position of the profile. Control this with a level.

If necessary, lay pieces of a bar or bar of the required thickness under the profile. - At the same time, fastening should be carried out directly through the inserted bars through and through.

Otherwise, the entire installation is carried out exactly as we described at the beginning.

End of installation

As you can see, decorating the window slopes with gypsum board with your own hands does not present a big problem if you do everything carefully and according to the installation instructions. After the installation is complete, you just have to putty the joints and paint.

We will not describe the rules for sealing joints of drywall sheets for a simple reason; on our resource this type of work is described in detail and does not need to be supplemented.

All or almost all of the slopes and trim

In this article, we examined some options for finishing window slopes. Of course, in one article it is impossible to fully cover the entire process of finishing such an important element as slopes.

After all, slopes are not only on windows but also on doors. When installing door slopes, there are also a lot of options, these are those that we described and add-ons, with a significant wall thickness, you can also use wall panels and many more different materials.

Once again, in one article it’s just not possible to consider everything. If you want to learn more about the possibilities of installing slopes for windows and doors, finishing with door or wall panels, you can always find out more about this by visiting our resource.

With us you will always find answers to your questions regarding construction and finishing works. After reading the articles, watching a video or photo of the processes, you can find the most acceptable options for yourself.

Good luck