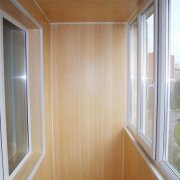

Decorating a balcony with MDF panels is not a bad way to ennoble a room

Oddly enough, but often, people begin to make repairs in the apartment from the balcony. Perhaps because they are afraid to use materials unknown to themselves in more spacious rooms, and first want to test them on a balcony or loggia.

Below will be given a kind of instruction on how to create with your own hands something interesting, modern and beautiful from your old balcony. The material for the decoration of our imaginary balcony, will serve, currently popular, MDF panels.

The content of the article

Everything is new - well forgotten old

MDF panels are, by and large, the good old fiberboard (fiberboard). With the development of technology, this material began to be processed differently.

Using a laminating film, and giving the panel the form of panels, manufacturers proposed a product with which we can create various surfaces.

So:

- The main direction of the use of MDF panels is the cladding of ceilings, walls and various frames. Including, from this material it is possible to create facades for built-in furniture.

In addition to the standard methods of application, you can come up with a lot. - The main advantages of MDF are strength, elasticity, practicality and price. The strength of MDF is approximately equal to ordinary wood, and its flexibility creates for it a number of certain advantages that a novice master will appreciate.

Also remember that interior decoration the panels of the balcony will not take away so much of your time and energy, such as plastering and puttying. Your repair will be many times faster and cleaner. - What exactly is meant. Creating a crate of walls, it is not always possible to get a perfectly flat plane, either because of the initial curvature of the walls, or because of the unevenness of the rails from which the frame is assembled. Due to its elasticity, MDF can hide the error in the difference of the crate belts up to 5-7 mm.

- Today, the market offers a great variety of shapes, sizes and colors of MDF panels. This material perfectly imitates surfaces made of wood or, for example, marble.

- The surface of the panels can be glossy, matte or textured. The standard panel size is 2600 * 238 * 6 mm.

There are also narrower options. They are mainly used for decorating walls in rooms, for example, in an entrance hall (seeDecorating the entrance hall with MDF panels: types of panels and installation), where the ceiling height is not large. - Using wider panels for cladding, you make your task easier, because the number of panels themselves and, accordingly, the number of attachment points are reduced.

Room preparation

So, you have to finish the balcony with MDF panels. What else do you need to know about this material?

MDF also has disadvantages. The panels are unstable to moisture and are not fireproof material, such as plastic (PVC).

Well, if a fire on the balcony is unlikely, then the appearance of moisture is a very frequent phenomenon. Accordingly, if your balcony can leak, then before installing the MDF it must be prepared.

So:

- First of all, it is necessary to close up all the large cracks and holes through which water can leak or simply pass air. For this we use mounting foam.

In hard-to-reach places or if the size of the slots is small, then you can use ordinary putty. - If previously your balcony was subject to regular mold, it is advisable to treat the walls with a special antifungal solution. MDF itself, due to the composition of the adhesive mixture used in the manufacture of panels, is immune to mold and various insects.

But they can perfectly develop under it, which can negatively affect, subsequently, human health. - The solution must be applied to the wall using an ordinary spray. Do not use a brush for this, as you cannot apply the solution evenly with a brush.

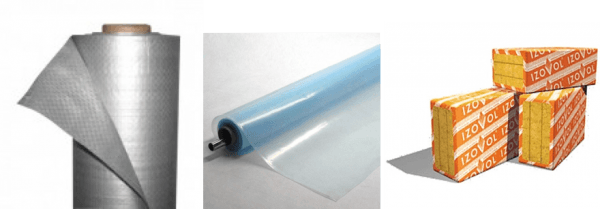

The amount of solution should be such that it flows down the wall, filling hard-to-reach spots. - If you consider that the performed actions will not protect you completely from moisture, or simply you want to insulate your balcony as much as possible, then the next step will be the installation of hydro-, heat- and vapor barrier.

Balcony insulation

You can warm the balcony yourself, with the help of special roll and block materials (seeWarming balconies and loggias in the home) Such materials are attached in layers with mastic.

There are also tough materials that combine the qualities of all three degrees of insulation.

So:

- The waterproofing layer is made continuous on the entire treated surface. There is no need to process the entire balcony, it is enough to perform insulation in places with wet surfaces, and where moisture can appear in the future.

Advice! It is important to remember that the insulation should cover the entire surface of the wall, including under the crate belts. Since otherwise, heat loss in your balcony can be up to 40%.

- The most modern and reliable way of hydro and thermal insulation today is spraying on the walls of polyurethane. This material is resistant to fungi, is environmentally friendly and fireproof.

Creating a balcony lathing

After preparing the balcony, it is necessary to assemble the rack frame to which the MDF panels will be attached. The frame can be assembled either from a wooden beam, or from metal profiles used in the installation of drywall.

So:

- If you insulated your balcony, then due to all layers of insulation, it will be difficult to fix the slats directly to the walls. In this case, the optimal solution would be to create an independent framework.

The advantage of this frame is that the resulting surface will be smoother. The downside will be that it will require more space, an average of 5 cm on each side. - If the thickness of the insulation does not exceed 3 cm, or you completely dispensed with it, then we make the usual crate of the walls using a 20 mm thick rail.

Metal frame

If you perform the assembly of a classic frame using guides (wall) and bearing profiles, then its value may exceed the cost of wood. Further it will be told how to reduce the cost and simplify the assembly a little, without losing strength.

So:

- For the manufacture of the frame, we use only the guide profile 50 * 50 mm. For work, we need: a puncher, a screwdriver, scissors for metal, a cutter, a plumb line, kapron thread, a building level and a building corner.

- A notch is a tool that connects two profiles, tearing metal on one side and bending it on the other. The cost of such an instrument ranges from 300 to 5000 rubles.

It is better if your prosecatal will precisely bend the created "antennae". - Of consumables, you will need only ordinary plastic dowel screws.

- First, we mark up the future wall plane. It is best to do this, focusing on a window or door, so that you do not get a feeling of curvature.

From different ends, we retreat from the window the necessary distance, putting marks with a pencil. Next, using a rule or MDF sheet, draw a line along the entire ceiling. - In places where the line meets the angle, screw the dowel screw.We fasten a plumb line to the screw and mark the wall exactly vertically.

We get a mark on the floor by connecting the opposite lines. The resulting plane will fully correspond to the plane of the window. - Next, along the planned lines, we fasten our profile around the entire perimeter. Mounting is performed as follows.

We drill a hole with a depth of 40 mm and hammer a dowel-screw into it. The profile must be incised in places where there is a curvature of the wall.

This will avoid profile deformation. - Then you need to install the main verticals for windows and doorways. We take a section of the profile of the desired length.

We insert one end of it into the lower, and the other into the upper guide profiles. The vertical is set taking into account the future slope.

- After that, we level the profile by level. It will be better to do this, focusing on the window or door. For these operations, a building corner is very useful.

Next, we fix the profile using the notch. We carry out fixing from two parties.

- Profile cutting is performed with scissors for metal.

Note! The notch creates a mount strong enough, even for drywall!

- As a result, the window vertical and wall profile should be turned to each other on one side. If there is no window or door on the sheathed wall, then we do not need a vertical at all.

But if the length of such a wall exceeds the length of the profile itself, then we install a double vertical at the junction. - We will do the same under the window, attaching a shorter profile to our vertical self-tapping screws, which will subsequently form the window-sill area and fix the belts under it.

- After installing the verticals, we begin to fasten the horizontal belts, to which, directly, the MDF panels themselves will be attached. Belts are installed in the same way as vertical ones and are fixed in the same way with a notch.

- The distance between the belts should not exceed 60 cm. And in places where mechanical stress is possible - 40 cm.

Where possible, create angles from a single piece of the profile by simply cutting the profile from the sides and bending it to a 90 degree angle.

- If a battery is installed on your balcony, then marking the level of the wall plane, do not forget to take into account its width. To close the battery use special decorative grilles.

Such a grill has an excellent appearance and retains the ability to access the battery after sheathing. - When making a cell in the frame under such a grid, leave an additional gap of 5 mm, otherwise it may simply not sit in its place. The upper horizontal of such a cell is set according to the level, and the lower one is already on the tape measure from the upper one.

- So, all our profiles are in place, now it is necessary to fix them in order to give rigidity to the structure. For this we use: either direct suspensions, or corners, which we will make ourselves from our guide profile.

- The corner is done as follows. The profile of the desired length is cut, bent at an angle of 90 degrees, and is fixed on both sides by the notch.

We fix one edge of the corner on the dowel-screw to the wall, the other we fasten with a self-tapping screw to our belt. - Fixing nodes are mounted from each other at a distance of no more than 1 m. In places where it is still advisable to place more fasteners, install them at your discretion. Our frame is ready.

Timber frame

The wooden frame is made similarly to the metal one. We only fasten the profile together using either furniture corners and self-tapping screws, or we make grooves in the boards and fasten them through with long self-tapping screws on the wood.

To make such a frame, use a wooden beam with a cross section of 50 * 50 mm:

- Such a frame does not require additional reinforcement, since its rigidity is sufficient for the loads experienced by the wall.

- Use longer dowel screws for installation.

Battens

Cases of the selection of such a frame have been described above. This type of crate is the easiest to perform.

Slat belts are attached directly to the walls. To align the plane in the right places, you need to put small cubes.

MDF mount

Next begins the direct decoration of the MDF balcony. Start lining from the angle most convenient for you.

The first MDF panel on the wall is always level. Panels are fastened with self-tapping screws.

Wooden slats can be mounted on nails, or use a construction stapler.

So:

- Some types of MDF are attached to belts for a special edge, as on plastic panels (PVC). The bulk of the species, held at the expense of a special bracket - Kleimer.

- The first panel in the corner is fixed through with a self-tapping screw, but keep in mind that the self-tapping head, subsequently, is closed with a decorative corner of MDF. The wall finish panel is also attached.

We put all the other panels on the kleimers. - We systematically sheathe the entire surface of the balcony, simultaneously cutting the MDF in height, along the windows and doors. MDF cutting is performed with an electric jigsaw.

Panels are cut very easily, so be careful not to miss the marks. - The layout of the panel for cutting under the windows is best done on the spot. If this is not possible, then do not forget to consider the depth of shrinkage of the panel into the panel.

- If you want to bring outlets and switches to the balcony, take care of the wiring in advance. Having sewn the place of direct mounting of the outlet, do not forget to mark with a pencil the place of its attachment.

Advice! No need to buy special sockets for drywall, no need to drill a wall and install a box in it. Conventional MDF sockets are best secured as follows.

Screw to the wall at a distance from each other in the width of the outlet mounting two short bars. Drill a hole in the MDF at this location.

The antennae-fasteners of the outlet will be wedged just in these little bars.

- Next, we cut the panels under the slopes. On the perimeter of the window or door we fasten the starting PVC profile.

We install our blank in it, and fasten the reverse end to our vertical. - The finishing stage is the installation of decorative corners of MDF. They are mounted on liquid nails.

The corner is universal. We close them both external and internal corners.

Here is our balcony finish. Watch additional videos on installing MDF frames and panels.

See more photos on the options for finishing balconies. Go ahead, fantasize and the result will not be slow to please you.

Good luck and success!