How is the interior decoration of the walls of fiberboard, chipboard and smallpox

Why dilute dirt, breathe cement dust, and clog the sewer with water with the remains of the mortar from plastering and cladding? Finishing walls from particleboard, finishing soft fiberboard, decorating walls from OSB - a small list of proposals.

How to make the right choice and what to focus on?

There is a solution to the problem, find out the pros and cons, cons and drawbacks of materials. Of course, they are reluctant to talk about negative qualities in stores, but there is information in the photo and video materials, there are just text descriptions and articles.

The content of the article

Positive and negative properties

Finishing materials, constituting a rich and diverse world, are divided into types, types, qualities, properties. Some of them are better, others worse, and therefore their price is lower, some are intended for external work, others can only be used for internal use.

Modern technologies allow to obtain universal materials:

- Wood-fiber boards (Fibreboard) are prepared by hot-pressing a mass of wood fibers assembled in the form of a carpet. Fibers are created by steaming and grinding wood raw materials from individual tissue cells, their scrap or groups of wood cells.

Fiberboard is resistant to humidity changes, used in the manufacture of the rear walls of most cabinets, drawer bottoms in cabinets, tables and other furniture, rough-to-touch surfaces are fiberboards. Positive qualities - low cost with a high service life, negative - a small area of application. - Chipboard (Chipboard) is obtained from wood chips and sawdust impregnated with binding, formaldehyde resins. Cabinet furniture, construction of roofs and partitions, chipboard wall decoration, interior design and other work are performed from this material.

Water resistance of products made of chipboard, their strength, ease of processing are widely used for the manufacture of economy-class furniture. This material holds fasteners well and reliably, a low price is added to these advantages, which determined the production of office furniture, finishing chipboard in kitchens and the bathrooms performed by a stove with increased moisture resistance.

The negative aspects include formaldehyde resins, which are not very useful substances. No children's furniture is produced from E2 chipboard, this material is prohibited for these products.

Chipboard of Austrian and German manufacturers is considered the most environmentally friendly, domestic manufacturers have a cleaner material - chipboard E1, its formaldehyde emission rate is much lower than type E2. Deep milling and manufacturing of all kinds of curly parts from chipboard is not performed, despite the hardness of the material.

Attention: Chipboard cutting work is carried out slowly so as not to get chips on the edges of the parts, and if the surface is cut with a very sharp knife, this will protect the coating from splitting.

- The development of MDF boards was carried out to improve the technology of manufacturing fiberboard. The developed process eliminated harmful resins and phenol and replaced them with the natural material lignin released during heating of wood.

It is characterized by excellent compactness, fiber adhesion, constant geometric dimensions for a long time.The combination of hardness and thickness made it possible to produce door frames and entire blocks, platbands from them.

A smooth, even, uniform surface of a certain density makes the processing of plates relatively simple. Negative properties have not yet been discovered, except for the lack of well-functioning production in the country. - Oriented particle board (OSB) is a fundamentally new species that has preserved the best qualities of natural trees. The main feature is the location of the chips in the upper and lower layers.

The multidirectionality of the fibers provides a set of positive qualities of this material. High mechanical density, for comparison, it is three times higher than that of plywood or chipboard and at the same time retains the flexibility inherent in wood materials.

At the same time, OSB boards lack the disadvantages of pure wood. They are not combustible, do not rot, are not affected by fungus and have zero hygroscopicity, which makes them indispensable bases for roofing.

OSB is used for interior decoration, wall, ceiling and floor cladding, frame housing construction, it serves as a substrate for a laminate or parquet, and is used for reusable formwork. Even such a small list of the use of OSB boards indicates its growing popularity.

How to usefully spend time

To carry out repairs with your own hands, it is not necessary to take an annual basic paid vacation and spend time relaxing on grueling work. It will be enough 2-3 hours daily for finishing work, and the result will please much faster than expected.

In the work of wood-fiber board

Wall panels - A convenient material for wall cladding that meets the requirements of customers. Laminated fiberboard for finishing walls is called so, but it has never been covered with a laminate.

One side of its surface has a thin layer of paper treated with a special composition, and the main components of the slab, of course, are wood fibers. The second side has a rough finish with a rough surface and is used where it is not visible.

So:

- Laminated fiberboard for wall decoration the size can be completely different, the main quality of the plate and its thickness.

Attention: It is impossible to acquire sheets similar to frozen waves for work. This defect tells that it has accumulated moisture and began to warp.

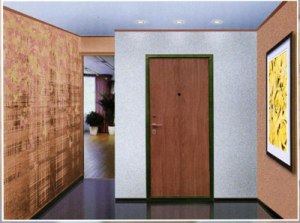

- The room can have perfectly even walls, and the finish with crooked hands reduces the efforts of specialists to zero. The situation may be reversed when the wall decoration with a laminated particleboard masks clumsy walls.

- Wall fiberboard panels are divided into three types. Typesetting rack, having the appearance of a lining, 2.5-6 m long, 10-30 cm wide and 8-25 mm thick.

They are equipped with a spike groove system. The panels are mounted on the wall quickly and easily with special clamps or brackets. - Tiled, represented by a variety of sizes of fiberboard sheets. The combination of panels of different sizes and colors makes it possible to get pictures of incredible beauty on the walls.

Fastening is carried out similarly to dial panels. - Leafy, outwardly resembling the usual hardboard sheet. Sheet panels occupy a wide, dimensional range with plain and various colors.

3D products are produced. Fasteners depend on the condition of the walls. - Wall decoration with laminated fiberboard and other types of panels are equipped with their own moldings, which include fittings and accessories used to decorate the joint of products and mask existing wall defects.

Fiberboard fasteners

The condition of the walls determines the way the panels are decorated:

- With a perfectly even wall and the absence of a humid environment, temperature drops and the panels themselves have an optimal thickness of 3-5 mm, they can be “planted” on the adhesive.

- Direct fastening to the wall is carried out by cuts itself.

- A wooden or plastic crate is arranged and a laminated fiberboard for wall decoration is screwed to it by itself with cuts, plastic or metal clamps.

Everyone determines the method of attaching wall panels to himself. Installing fiberboard directly to the wall has its own nuances. A preliminary primer of an already aligned wall is carried out.

So:

- Fiberboard interior wall decoration starts from the corner. The first sheet, aligned vertically, is glued to the wall.

The next part is lubricated with glue, snap into the lock first and also glued.

Attention: If you do not want to bother with glue, you can use nails with decorative hats.

- Fiberboard sheets are directly attached to wooden walls and sip panels.

- Brick and concrete walls are pre-marked, holes are drilled, plugs for self-cutting screws or nails are driven into them, with which the panels are fixed.

- Practice shows that without the construction of the crate can not do. At the same time, centimeters of space are lost, although small, but opportunities are obtained to hide the most hopeless walls, hide communications, and lay sound-insulating materials.

- When installing the battens, a level and a plumb line are used, the step should not exceed 30 cm. After fixing the sheets, the molding is installed.

Wood chipboard and cronospan in operation

Modern technology allows you to get polished chipboard, safe for health.

The scope is determined by the properties of natural wood:

- Roof sheathing, chipboard wall decoration, used for the manufacture of wall panels.

- Flooring elements are produced, used in the form of bases for various coatings of linoleum, carpets or floor.

- Furniture, shelving, shelves, various types of packaging are produced.

- The construction of fences, collapsible structures.

- Used for decoration and decoration, which is possible with such an original surface texture.

- The internal structure of the chipboard sheet is usually hidden from prying eyes, and only the end opens the innermost. Finishing the ends of chipboard is not only for obtaining aesthetic surfaces.

The ends are sealed even in places hidden from the eyes to protect products from moisture in the air, from fungi, microorganisms and insects that can damage wood. - Chipboard edge trim depends on the finish of the sheet. The laminated sheet, which is planned to be used without staining and coatings, requires an edge band of the appropriate type on the visible edge.

Hidden edges are puttied and sealed with a construction bandage. - The laminated, polished sheet is primed, the edges are putty, sealed with a construction bandage with an inlet on the sheet plane, the bandage is also putty and the entire surface of the sheet is painted.

- Cronospan wall decoration is supplanted by other, more modern materials. Cronospan used to be used for interior decoration of offices and used to repair non-residential premises.

In residential premises it could be seen in the hallways and halls. The weak point of this material was its poor resistance to humid environments. - Today, panels are already available that are suitable for finishing glazed balconies and loggias.

- It is installed no more complicated than plastic, but there is an inconvenience. Joining panels in the corners should be glued with special corners of the same material. Corners are glued to liquid nails.

Decorative, moisture-proof panels create the illusion of natural materials, they are not inferior, but surpass them in many qualities. In the modern construction market, not only there are materials convenient in work, but also instructions on their application and use are offered.

Particleboard is not a bad material for decoration. It aligns the walls well and you can immediately glue the wallpaper on it. You can quickly hang a carpet on a wall chipped with chipboard, carnations driven into a panel hold rather firmly and reliably. But in the need and effectiveness of fiberboard, I personally doubt it, I just do not see the feasibility of such a finish. Bad rumors are circulating about the kronospan, it is probably better to beware.

Chipboard - old Soviet material, time-tested.