Laminate wall decoration: features and installation

Finishing work in the room helps to decorate and diversify the interior. There is a very large selection of finishing material on the market that is used for such purposes.

The laminate wall finish looks quite interesting and unusual.

The content of the article

The structure of the laminate and its types

Laminate for wall decoration began to be used relatively recently. As a rule, its use was only as a floor covering.

But due to its technical characteristics and appearance, this material has passed into finishing work on wall and ceiling surfaces.

So:

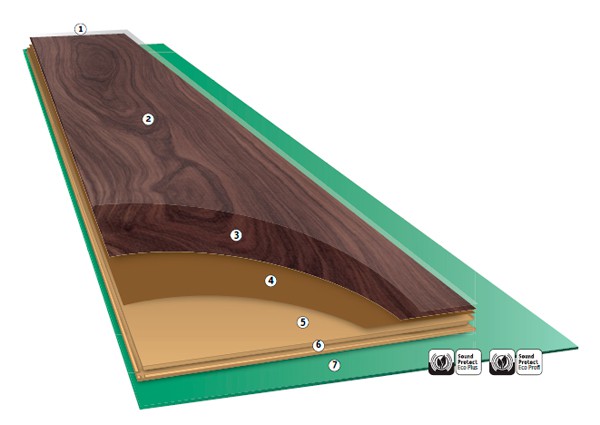

- Such material consists of several layers. The top layer is protective for this material.

It is a single-layer or two-layer coating. It consists of resins (acrylic and melamine). - Thanks to this layer, the surface of the laminate does not absorb moisture and various contaminants. It does not fade and is not exposed to temperature changes.

The quality of such a protective layer determines the class of the laminate and its wear resistance. - The second layer is the decorative design. It is a special high-quality paper or foil.

It is also used in the manufacture of furniture. Such paper or foil is processed on special equipment and impregnated with means to give strength. - The third layer is an HDF-plate, fiberboard or particleboard. This layer has high strength and moisture resistance.

Note. The most recent (lower layer) base of the laminate is a sheet of plastic or processed paper with special resins. It is durable and reliable, all types of laminate are divided into classes.

Laminate classes, where and what type can be used:

- The first grade is 21.

It has a rather long service life, which is 7-10 years. It can be used in the bedroom, living room, nursery (seeHow to decorate the walls in the nursery: consider some options) That is, in residential premises. - Next class 22.

Its service life is not more than 5 years, but, as practice has shown, with proper handling, it can serve more. It can also be used in the residential area. - 23rd grade laminate is used for 5-6 years. Quite often it is used in finishing work in the kitchen and dining areas, corridors.

- Class 31 laminate is more acceptable for office premises.

Its service life is no more than 3-4 years. If you use it in the house, then this period increases to 10-12 years, since there will be no such treatment with him as in the office. - 32 class is considered the most optimal finishing material for home premises. Its service life is 5-6 years.

- The 33rd grade laminate is quite practical.

If it is used in the house, then its service life will be about 10-12 years. If in office premises, then he will serve no more than 5 years.

Note. All these criteria help the consumer decide on the choice of laminate flooring, since each class has its own price.

Laminate surface

The surface of the laminate that is used for wall decoration may be of different quality. There is laminated, which in its appearance resembles the structure of a tree.

On it you can see the recesses, like on wood. Laminate with such a surface is most often used in the decoration of wall surfaces.

It creates an atmosphere of comfort and coziness.

So:

- The glossy surface of the laminate in its appearance very much resembles a tree that is varnished. The texture surface is a relief design with pronounced wood fibers.

- There are types of laminate that resemble an old tree. They are very popular at the moment.

- There is a matte surface that goes without too much gloss and this type of surface is considered the most practical, since it is very easy to clean, but there is not such a protective top layer as in previous types. It is for this reason that scratches may appear over time.

- The embossed surface of the laminate is also very popular, which has distinct “strokes” of wood. Although the material itself will not have any defects.

The photo shows the diverse surface design of the laminate. - There are types of laminate with imitation ceramic or marble tiles. The sizes of this material are different.

Choosing a laminate for wall decoration

Laminate flooring walls to a greater extent depends on the method and method of laying the material.

At the moment, there are several options for bonding material panels to each other:

- Glue laminate.

- Blade.

- Groovy.

Adhesive laminate

Mounting Method:

- If you choose the first type of lock and installation, then it is worth considering that it can not be mounted on a crate.

- All this is due to the fact that the area in contact with the laminate with the crate is quite small, and here you can get low-quality finishing work on the wall surface.

- It is mounted using special glue on a pre-leveled surface.

Tip. For this, drywall is used, without which repair work and plaster are not currently being carried out.

- Drywall installation is carried out on a special frame, which is made of metal profiles.

In order to fix it to the surface you need:

- Dowels.

- Hammer drill.

- Screwdriver.

- Self-tapping screws.

- Level.

- Roulette.

Further:

- That is, a metal frame is made on the surface, the cell width of which should be at least 40-50 cm. Drywall sheets are mounted on it with self-tapping screws and a screwdriver.

Tip. It is worth considering that the joints of such a material can be treated with plaster, or it may not be necessary to carry out such actions, since this will not affect the finishing work using a laminate.

- In order for the finish to be better and more reliable, it is nevertheless worth gluing the joints of the drywall sheets with a special tape and apply a layer of putty on them.

Plastering the surface is a little more difficult, as the process itself is time-consuming and there is always a lot of construction waste left after it.

To smooth the surface with plaster you will need:

- Starting plaster.

- The finish line.

- Sandpaper.

- Two spatulas.

- Capacity for a batch of solution.

- Construction mixer.

- Level.

- Building mesh for plastering the surface.

Stages:

- First, the starting plaster is applied to the surface in several layers, each of which must completely dry and is treated with sandpaper. Then layers of finishing plaster are superimposed.

The whole process is similar to applying the starting layer.

Tip. After the surface has already been leveled using plasterboard or plaster, it is necessary to treat it with a primer.

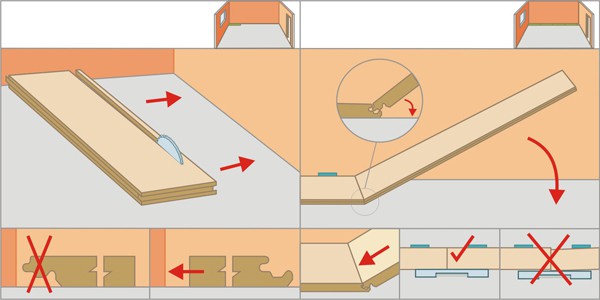

- Only after that it is possible to glue the laminate on a flat surface with a special tool, each element of the finish is checked according to the level. Installation can be done both horizontally and vertically.

Everything depends on the chosen design of the room. The whole process is quite simple, and you can do it yourself.

Tip.

It is necessary to apply special glue to the wall surface itself and to the inside of the laminate. This ensures the strength and reliability of the finish.

Blade laminate and its installation method

This type of coating has a stronger and more reliable lock. It is reliable and practical.

Finishing the wall with this type of laminate begins with the manufacture of crates on the surface.

For this you need:

- Wooden planks of the same diameter.

- Level.

- Dowels.

- Self-tapping screws.

- Hammer drill.

- Screwdriver.

- Jigsaw or saw.

Stages:

- The crate is attached to the surface with dowels, and the elements are fastened together with screws. It is necessary to measure each of its elements strictly according to the level.

The quality of finishing work will depend on it. - It is necessary to mount the laminate on the crate using special glue, which is applied to the surface of the crate and to the surface (inner) of the laminate. Small cloves are also used, which will only increase the quality and increase the strength of the finish.

Tip.

For this, you can also use a construction stapler with large staples. They will firmly fix the material to the surface and if you select their desired shade, they will not be noticeable at all.

Sheet pile laminate and its installation

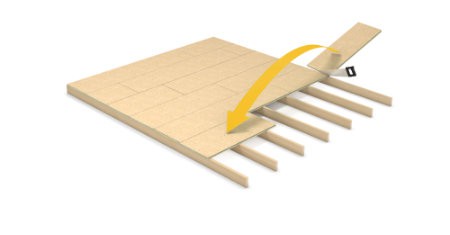

Sheet piling laminate has a fairly strong lock. A wooden crate is also needed for its installation.

He attaches to it with:

- Nails

- Self-tapping screws.

- Bracket of a construction stapler.

So:

- In general, the whole process resembles the installation of a plastic lining. You can watch it on the video.

- You will also need to measure each element of the decoration using a level. To make it convenient on the surface, you must first draw the crate and only then choose the optimal option for installing the laminate.

Tip. The installation of the laminate on the wall surface should begin with the fastening of whole parts of the material.

- To do this, it is necessary to clearly measure the width of the wall and determine the length of the stripes of the laminate. This is necessary so that after the work of the waste material is left, as little as possible is left.

- There should be whole elements on the visible part of the wall. You just need to calculate the location of the laminate in such a way that if there are non-integral parts, then they will be evenly distributed on both sides of the wall.

Quite often, finishing part of the wall with a laminate, and not a whole surface. It all depends on the design and design.

As a rule, a “torn” effect is created when the laminate is unevenly distributed on the surface. In this case, you can not do without drywall, which, like the laminate, is attached to the frame.

That is, there will be an opportunity to create the integrity of the design. The cracks between the laminate and drywall are sealed with putty or a decorative plinth.