Gvl decoration of walls, ceilings and floors

All these abbreviated names of building products are stuck in my teeth. One wants to shout, but write in full what they are called, why and where they can be used.

Gypsum fiber sheet or GVL is one of the finishing materials obtained from gypsum reinforced with technological additives and dissolved pulp. What is so special about it?

The content of the article

Familiarity with gypsum sheets and boards

Homogeneous material that does not have a cardboard coating (shell), this moment is clearly visible in the photo. The scope determines the type of sheets.

Apply either ordinary sheets (GVL) or moisture resistant (GVLV). Wall decoration DIY GVL is possible when repairing a house, apartment or other buildings.

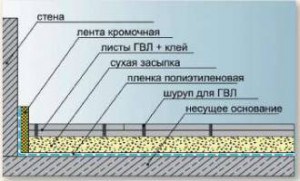

A big secret will not be revealed if we say that modern construction prefers to use "dry" processes in the construction of houses, buildings and their subsequent decoration. All wall, ceiling and floor structures can be covered by these processes.

So:

- GVL is rather strong material and safe; it does not support combustion.

- Gypsum fiber and gypsum board (GWP) have higher moisture resistance than gypsum board.

- GVL finishing is any decoration of walls, ceiling, floor, inclined surfaces. It relates to an alternative “wet” method when plastering is used with a cement-sand mixture diluted with water.

- Now preference is given to the construction of environmentally friendly wooden houses, can you imagine it being plastered?

- The only thing that can be plastered in it is the foundation and floors.

- To apply for the decoration of GVL, which also "breathes", is to preserve the original plan, to obtain a comfortable, clean house. The alignment of the walls inside of the gvl is the most convenient form.

- You can hide communications, the walls turn out to be smooth and beautiful, the defects and flaws resulting from the construction are hidden.

- Plaster fiber sheets and slabs are the same as reinforced concrete in concrete products. The compressed mixture in strength exceeds just gypsum and has a higher viscosity.

- Imagine how you can hammer a nail into drywall or screw a screw into it? In the GVL sheet, the nail is held, as in a tree, as well as the screws that twist without problems.

- The GVL material is processed by a planer, a saw, a file, an analogy of working with wood appears.

Attention: Seasonal temperature changes do not cause plate deformation due to the low coefficient of linear expansion.

- High sound absorption and fire resistance, environmental cleanliness with neutral acidity for people.

Physical and technical properties for clarity are presented in the table:

| Name of material | Flammability | Density | Swelling percentage | Thermal conductivity | Bending Strength MPa |

| GKL | G1 | 0,85 | Up to 30 | 0,25 | 2 |

| GVL | G1 | 1,25 | Up to 30 | 0,25 | 5,5 |

| LSU | NG | 07 – 1,2 | 9,1 | 0,21 | 0 |

- Interior decoration gypsum board or sheets can reduce the time it takes to complete the finishing work and the cost of manual labor, which ultimately comes down to the overall cost savings for construction.

- On the video materials it is clearly seen that work with this material is performed by conventional tools available in each house, and elasticity allows them to be used for facing both convex and concave structures.

- GVL sheets and plates are mounted on metal and wooden frames, or can simply be glued.

- It turns out a flat, smooth surface, prepared for painting, wallpaper decorationtiling.

- The versatility of the application determines the arrangement of interior partitions, the device of floors, false ceilings.

Application in special rooms

So:

- In basements with a humidity index of not more than 70%, they are used as bases for floors and for wall cladding, followed by tiling or painting.

- In residential areas with high relative humidity in kitchens and the bathroomsbut without direct water.

- The device of partitions in pantries and utility rooms, walls and foundations under the floor.

- Sports, gymnasiums, courts, where high demands are placed on the rigidity of walls, floors and ceilings.

- Equipment for industrial and civilian premises with increased fire safety requirements.

- Elevator shafts, escape routes, surface finishes with specific environmental requirements. The radiation level of GVL sheets and plates is three times less than brick products.

- Attic and attic rooms, where the ability to not perform reinforcement of seams and joints is so relevant.

It can be noted that GVL boards can be attributed to complex, universal, finishing materials for residential, industrial, non-residential premises. Facing any internal surfaces, regardless of their components: concrete, brick, wood, flat surface or curve does not matter.

Plasterboard material for wall cladding

GVL is issued with a polished or unpolished surface, with the edges having bevels and without them. Chamfers are designed to create durable, but inconspicuous seams when filling joints. GWP, without chamfers, is used when installing the inner layers of wall cladding, partitions, and when the GVL is joined with rectangular ends, it is necessary to manually chamfer them at an acute angle of 22.5 °, no reinforcing tape should be applied to the seams.

What is special about wall cladding

With frameless wall cladding, and easier when sticking sheets to the surface, there are certain rules and instructions:

- The width of the vertical gaps between the sheets should be 5-7 mm, the distance between the sheet and the ceiling 5 mm.

- Joints of gypsum sheets are sealed with special putty without gluing a reinforcing tape.

- When sticking to the wall, glue for gypsum plaster and also special plaster, which is applied in a continuous strip, are used.

Attention: When sticking a sheet on long GVL strips on not aligned walls, the step of the strips is not 600 mm, as with GKL, but 603 mm to maintain a gap of 5-7 mm.

The frame structure of the walls, the equipment of partitions and ceilings does not do without its nuances and features:

- A profile of 60x27 in size is placed through 603 mm.

- The fastening of the GVL sheets is carried out by special double-entry screws with countersink heads.

- The sheets are fixed to the frame through the same gap of 5-7 mm.

- When equipping two-layer partitions, it is allowed to fasten the first layer of GVL to the frame without gaps, but the second layer is attached to the first one in compliance with the established gap of 5-7 mm.

- For the ceiling, 10 mm thick gypsum fiber sheet (GVL) is taken and most often used.

- Their installation is carried out directly on the frame of one level. This is because the expected gap of 5-7 mm between the joints of the sheet must necessarily lie on the profile.

- The profile step of the software 60x27 is 1206 mm. With a greater thickness of GVL by 2 mm, that is, its thickness is 12 mm, the distance of the attachment points is reduced to 650 mm.

Help on using the material

Gypsum fiber sheet (GVL), decorated with decorative plastic, is one of the most expensive, but also the most durable coatings.Scratch resistant material, does not respond to ultraviolet radiation, does not interact with chemical reagents, surface sanitation is allowed.

Medical institutions, where there is high traffic flow and there are increased sanitary and hygienic requirements, apply this facing material and quite widely. Its price ranges from 550 rubles. 850 rub / sq. m

They not only decorate the walls, but also solve several practical problems of leveling and floor finishes.

So:

- Before laying GVL, old coatings are removed to the base.

- It is necessary to remove all loose parts from concrete.

- If the work needs to be done on several concrete slabs joined together, the gaps between them must be eliminated. Modern plastic compounds are on sale, it is better to putty them.

- To determine the level of overlap, measurements are taken of all corners of the room. The highest point will serve as a guideline for raising the floor, given the location of communications.

Dry methods are also used for outdoor work. Ventilated facades with airbags and insulation inside, siding, but more on that another time.