Wall decoration with decorative panels: do it yourself

Facing decorative panels are becoming more and more popular every year. The construction market can offer you decorative panels for interior decoration that will satisfy every taste.

Decorative cladding panels for interior decoration are made of various materials that differ in shape, texture and color. The range of products can satisfy the most unusual requirements of consumers.

The content of the article

Requirements for facing panels

Panels that are used for decoration of residential premises must meet the following requirements:

- they must have sufficient strength and at the same time be flexible and resilient;

- decorative panels should be made of environmentally friendly materials;

- they must tolerate temperature extremes;

- Resist moisture

- be fireproof;

- decorative panels should simply be mounted and not be afraid of synthetic detergents;

Using decorative panels for interior decoration, you can solve several problems at once:

- mask construction defects;

- walls can be perfectly aligned;

- decorative panels can imitate a variety of natural materials (stone, brick, wood and the like);

- under decorative panels you can hide all communications (wires, cables, ventilation systems);

- using panels for wall cladding, you significantly increase the sound and thermal insulation of the room;

According to the form of manufacture, decorative panels are divided into three types:

- sheet panels are the largest panels, their dimensions (width - length) are 1220 by 2440 mm and reach a thickness of 6 mm;

- tile panels are square panels, their sizes are 300 by 300 mm, or 980 by 980 mm;

- rack panels - are assembled from racks, their sizes are:

- length from 900 to 3000 mm;

- width from 130 to 300 mm;

- thickness is from 8 to 12 mm;

Material for the manufacture of decorative panels can serve:

- polyvinyl chloride (PVC);

- wood;

- chipboard (chipboard);

- wood-fiber board (MDF) (MDF);

- laminate (seeLaminate wall decoration: features and installation);

- veneer;

Stone decorative panels for interior decoration

Decorative panels will help to facilitate and accelerate the process of finishing the room. Manufacturers from different countries use different compositions for the manufacture of panels.

One of the companies in Spain produces panels from the following materials:

- fiberglass;

- polyester resin;

- natural stone powder;

- dyes;

Such a composition can reproduce panels for concrete, old stone, brick and others finishing materialsThese panels do not fade over time, tolerate temperature extremes and high humidity.

The size of the flat panels is 2.8 by 1.3 m. In addition, panels for arches with a diameter of 1 and 2 m, as well as panels for finishing corners with a height of 2.85 m are available.

In the United States, the production of panels imitating the texture of stone with embroidery has been established. Such panels are made by pressing wood under the influence of high pressure and high temperature.

At the same time, lignin is released from the wood, which is the binding substance. As a result, a material is obtained that is not inferior to concrete in compressive strength.

The size of the manufactured panels is 1.22 by 2, 44 m and a thickness of 6 mm. Moisture-resistant panels from Brazil are made of wood-fiber board.

A feature of this material is that its base consists of eucalyptus fibers with its natural oils and resins.

The widespread use of these panels for decoration is due to the following advantages:

- The panels are manufactured by pressing under high temperature. In this case, lignin is released, which is a binding substance.

- When solidified, lignin forms a very strong compound. Therefore, fiberboard panels with eucalyptus fibers have high strength and durability.

- It is an environmentally friendly material as synthetic resins are not included in its composition.

- High moisture resistance of these panels allows their use in the decoration of rooms with high humidity.

- The front side of the fiberboard panels very accurately copies the texture of marble, granite and other natural stones.

- The acrylic coating of the panel protects it from the negative effects of synthetic detergents.

Eucalyptus panels are very widely used in the decoration of a wide variety of rooms:

- hallways;

- halls;

- attics;

- balconies and loggias;

- in the interior of exhibition halls;

- decoration of shopping centers;

- for the manufacture of theatrical scenery;

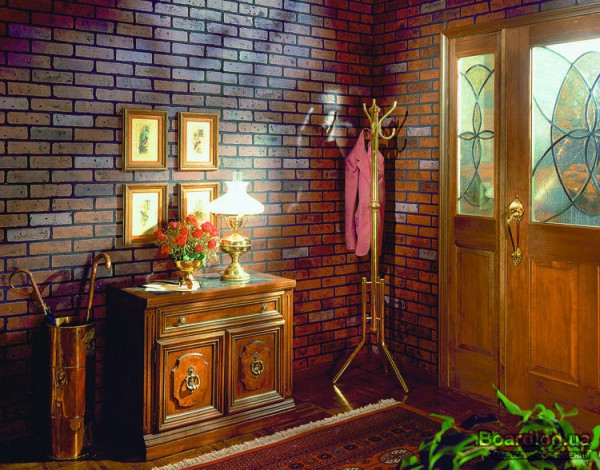

Brick decorative panels for interior decoration

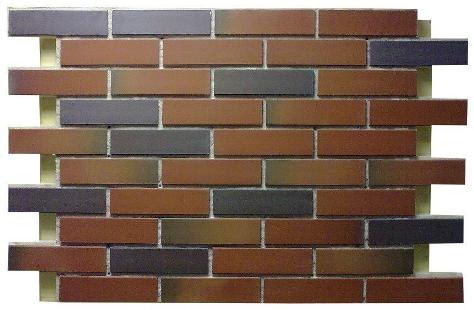

Wall panels imitating brickwork, as a material for interior decoration, appeared on the construction market recently.

PVC or MDF panels can be easily styled as bricks. Such panels practically do not differ from natural material.

MDF panels, stylized as bricks, are made by dry pressing of wood shavings. Under the influence of pressure and high temperature, lignin is released from the wood, which is the binder.

Such panels can be used to decorate rooms with high humidity.

The following properties brought wide popularity to these panels:

- First of all, it is environmentally friendly material;

- It has good moisture resistance;

- these panels have great strength like lignin, when hardening it becomes very durable;

- MDF panels are hygienic, they can be washed with synthetic detergents;

- upon order, MDF panels can be produced with refractory properties;

Brick-styled plastic panels are made from polyvinyl chloride (PVC). They completely imitate the structure of natural brickwork.

PVC panels have many positive qualities:

- they have a very long life;

- they are hygienic, they can be easily disinfected;

- they have good heat and sound insulating properties;

- they are able to withstand large temperature differences;

Decorative wall panels made of PVC, stylized as brick, have found their application in the design of such premises:

- the shops;

- Offices

- hotel lounges;

- in public buildings;

- in private houses and apartments;

- they can finish the ceilings;

- from them create arches, partitions, columns;

- they are indispensable as a decoration for bathrooms and kitchens;

- they are easily mounted; if desired, this work can be done independently;

Plastic is more common in the manufacture of wall panels than MDF or wood. The reason for this, first of all, is its cost.

If we add to this its strength, durability, environmental friendliness and fire safety, then it will become clear what its attractiveness is.

The most popular of all plastic panels is imitation of masonry. And the demand for this product is constantly growing.

The advantage of plastic panels becomes even more obvious when the time is right for their installation. This work can be done with your own hands and thereby save a lot of money.

Decorative Tile Panels

Tiled panels are square with a side of 30 or 90 cm. The surface of such panels is embossed with a variety of patterns and a wide range of colors.

Choosing a different texture and color, you can lay out unusual, unique compositions on the wall or ceiling.

Tile panels are attached with glue directly to the wall or ceiling, provided that the surface is flat. If the surface is uneven, then the panels are mounted on a wooden crate using kleimers.

Grooves are arranged on the sides of the connection panels. The panels are interconnected using the tab, which is inserted into the grooves.

Tile panels are made of the following materials:

- Fiberboard.

- MDF.

- Chipboard;

- PVC

- wood.

Decorative rack panels

Slatted panel panels look like an ordinary lining.

Rack panels are boards with a length of 0.9 to 3 m. The width of individual boards ranges from 13 to 30 cm, and the thickness is from 8 to 12 mm. Rack panels are attached to the wooden crate with the help of clamps or self-tapping screws.

Such panels are well used in cases where it is necessary to sheathe a small room or a room that has many angles. The panels are joined by a spike-groove or groove-groove method. In the latter case, a tab is used to connect the two panels.

The material for the manufacture of rack panels is:

- wood.

- Fiberboard.

- Chipboard.

- PVC

- MDF.

In order for the finish of the slat panels to have a finished look, it is necessary to purchase the appropriate accessories for it (start and finish trims, interior and exterior corners, ceiling and floor skirting boards, and the like).