Drywall ceiling decoration - how to do it right

Today we will consider such a question as decorating the ceilings with plasterboard with our own hands. It's no secret that the final result of finishing any surface depends on how this surface is prepared.

If the installation is not performed correctly, problems may arise during the decoration, and the end result will simply disappoint you. We will consider the various difficulties encountered during installation, as well as ways to solve them.

The content of the article

- Proper installation for a high-quality finish

- Installation of drywall on the ceiling in the attic

- Correct marking - quality results

- We mount guides

- Connectors - The Missing Solution

- Mounting the ceiling profile on the sides

- Suspensions, control cords - continue installation

- Connecting Bracket - Not Sea Crabs

- Little installation tricks

- End of installation of the frame of the inclined part

- Part horizontal - everything is the same

- The right frame - a great finish

- Mount GKL

Proper installation for a high-quality finish

Installing a plasterboard ceiling correctly is not an easy task. Drywall finishes are also different.

Let's look at not the easiest, but not the most difficult option.

Installation of drywall on the ceiling in the attic

We will not install on a simple, even ceiling, but on the attic type ceiling.

Correct marking - quality results

So:

- We start by beating horizontal lines. For this, it is good to use the laser level.

- But if you don’t have one, you can use the water level and the paint cord.

- Mark with a level and then mark with a cord.

This marking is necessary for the exact installation of the rails.

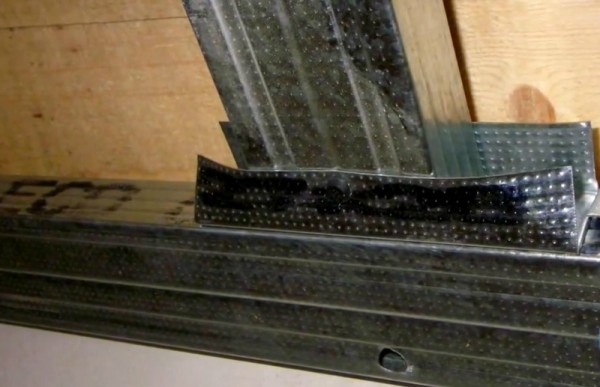

We mount guides

- On the drawn lines we mount a guide profile.

- We will fix the profile on the dowel - nails. The distance between fasteners should not exceed 1000 mm.

Our advice - choose the method of fastening based on the materials of the walls of the building.

- Since our ceiling has sloping parts, we also install a guide profile on them.

Connectors - The Missing Solution

If the width of the room is greater than the standard length of the profile, it will require lengthening. For this, there are special extension brackets for the profile.

Mounting the ceiling profile on the sides

So:

- Next, it is necessary to mark the installed guide profile in multiples of half of the GKL sheet, the ceiling profile is installed according to these sizes.

- In this case, the joint of the GKL sheets falls in the middle of the ceiling profile, which is what we need.

- With a width of GKL sheet of 1200 mm, we install exactly in the middle another ceiling profile.

- Thus, the ceiling profile will be installed for every 600 mm sheet of drywall.

- Fastening the ceiling profile to the guide is carried out using metal screws.

- In places where the ceiling transitions from the inclined part to the horizontal, it is necessary to install another ceiling profile.

- Next, you need to mark the middle of the ceiling profiles with a marker. These marks will allow us to navigate perfectly when installing GKL sheets.We fit the sheets to the marks and fix. Simple and convenient.

- We install all other ceiling profiles. The distance between them is also 600 mm.

- Next, with the help of a marker, it is necessary to carry out marking in places where we will install transverse profiles. They will subsequently form cells.

Our reference - The distance between them should be within 500 - 600 mm from each other.

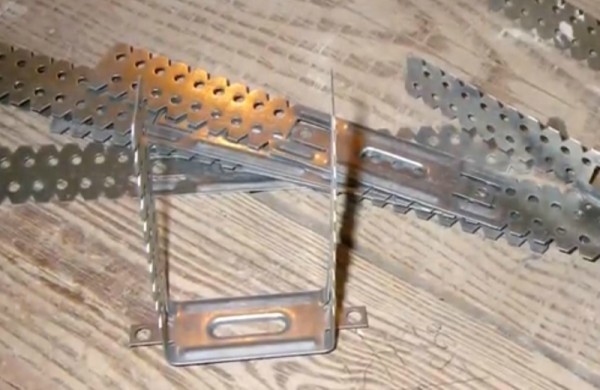

Suspensions, control cords - continue installation

Now you need to install the suspensions for attaching the ceiling profile to the ceiling and inclined walls:

- Install suspensions at a distance not exceeding 1000 mm from each other.

- Between the end profiles, pull the cord. With it, we will align all ceiling profiles. Thus, we get an even, uniform plane.

- The hangers are mounted on an inclined wall, now it's time to align the ceiling profiles with the cord and attach the hangers to them.

- For fastening we will use metal screws. Excess suspensions must be bent in the opposite direction.

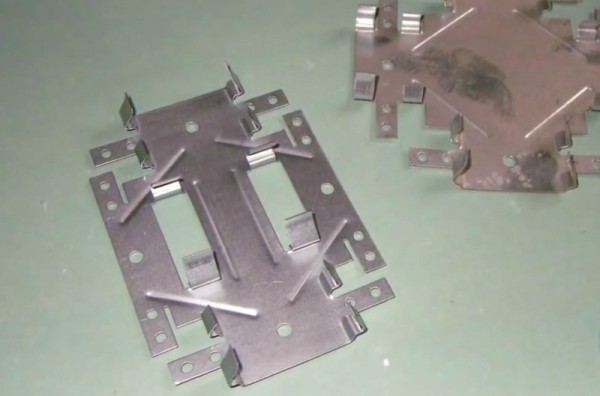

Connecting Bracket - Not Sea Crabs

For fastening transverse profiles, you will need to use a special bracket. People call it crab. The crab forms a reliable connection.

Little installation tricks

However, we have places where the use of crab is impossible. It is not possible to insert a crab into the lowest profile of an inclined wall.

One face profile is closely pressed against the wall. Here are the first difficulties.

Special brackets are on sale with which you can connect the profile at almost different angles. The price for them is cheap, another thing is that they are not always at hand.

We apply, so to speak, a little trick. We will use a small piece of the guide profile to fix the transverse one from the end to it.

After all, we cut the guide profile, we still have a sufficient number of segments. Why throw them away?

Let’s put it into action. The figure shows how to do this.

End of installation of the frame of the inclined part

So:

- We install the crab brackets in their places.

- It was the turn of installing transverse sections of the ceiling profile. They are inserted into the lower part of the guide profile, and then snap tabs sticking out of the crabs.

- When all the transverse profiles are installed in their places, the flags of the crabs are bent towards the profile and metal screws are twisted into them.

The frame is aligned and secured. He is ready to mount drywall sheets on it.

Part horizontal - everything is the same

This we performed part of the frame located on the sloping side of the ceiling. We need to do the same work on the horizontal part of the ceiling.

So:

- Aligning the ceiling profiles with a stretched cord, it is necessary to make, with a marker, marking for the installation of crabs.

Our advice - crabs should be positioned so that the subsequently formed cell is 600X600 mm. This size allows you to improve the ceiling stiffness of the frame.

- After marking and installing crabs, it is necessary to install segments of the ceiling profile.

Installation and fastening is similar to what we performed on the inclined part of the ceiling.

The right frame - a great finish

We have assembled an even and fairly rigid frame. If you do everything correctly, then in the future it will be very convenient for you to putty and finish the surface.

If for this work you invite an outside master, be sure that he will like such a surface. A solid and non-bending surface is ideal for any ceiling finishes.

A rigid frame just solves this problem. Carefully inspect the entire frame.

During installation, you can skip fastening in some places with screws. If such places are found, tighten the missing screws.

Mount GKL

We begin to work with GKL. We will prepare the sheets of the right size.

Step one - start with the slope

- It is necessary to start installation from the inclined part.

- Set the prepared piece there.

- Next, we begin to screw it with screws to the guides. The main thing is not haste and accuracy.

It is important - the head of the self-tapping screw should be completely immersed in the FCL, while it is not worth it to immerse unnecessarily. It will be enough 1 mm.

Rules for installing screws

The question may arise - at what distance from each other is it necessary to screw self-tapping screws when plasterboard ceilings are done with your own hands?

The distance between the screws should be between 150 - 200 mm.

Our advice is that it is very convenient to screw the screws into GKL sheets along pre-marked lines. Make markup, it will be very convenient for you to screw in the screws, without being distracted by the constant determination of their location.

This advice is not binding, and serves only to facilitate the work.

Maybe for an experienced master to determine by eye the exact location of the screws and not be difficult. For a beginner, the question of how to trim the ceiling with plasterboard is simple and convenient, this advice is not superfluous.

GKL installation on the horizontal part

The inclined sides are sheathed, it is the turn of the horizontal region. To facilitate the work, it will not be superfluous to additionally prepare.

To do this, make two wooden stops from improvised material. How to make them can be seen from the figure.

Their design is quite simple and allows you to perform all the work together with an assistant.

Wooden emphasis in the wedged state well holds the GKL sheet, pressing it to the frame. Their use will not baffle you with the question of how to finish the ceiling with drywall together, without certain skills.

GKL mount horizontally

So:

- After leveling, screw the drywall sheet to the profile.

- When the sheet is fixed, the stops can be removed and used to hold the next sheet.

Our advice - before covering the ceiling, do not forget to conduct all the wiring for future lighting fixtures.

Without fail, secure the sheets for all cells in the profile. This will achieve a stiff coating.

Rules for the installation of drywall

When installing sheets on the ceiling, you may encounter the fact that the whole sheet is not enough to cover the entire space in length. It's okay, in the future these places will be closed by GKL segments cut to size.

If you are faced with such a question, fasten the sheets in a run-up.

To the question - how is it?

We answer: If the installed first sheet does not reach the opposite wall, the next sheet must begin to be fastened from the wall to which the first sheet did not reach. The third, from the wall to which the second sheet did not reach, and so on.

It turns out, as if in a checkerboard pattern - in a run.

End of installation

When the main sheets are installed, it is necessary to measure the areas not covered with gypsum plaster, cut pieces of the required size and fix in place.

Important - on all cut pieces before installation, remove the chamfer. This will allow in the future, when finishing seams, to perform high-quality finish.

The seams will be strong, they will not form cracks in the future.

Our advice - after you have completed the installation of the gypsum plasterboard, check if all the screws are screwed up. Otherwise, their hat will interfere with the decoration.

This can be done with a spatula. Guide them to the attachment points and tighten all the screws that hook on the spatula.

All or almost all for you

That’s basically it. It remains only to repair the seams, putty the surface and perform decorative finishes.

Our resource has many articles on the types of finishes (seeCladding the ceiling - all the main "tricks") There are many great photos and videos of various design decisions.

The video decoration of the gypsum board ceiling on our website is presented with detailed voiceover comments by specialists. Having familiarized yourself with these materials, you can learn a lot of useful things for yourself.

Good luck to you!