Ceiling lining: types of material

What is a ceiling lining? These are finishing works on the ceiling surface, with the help of which the interior is given a highlight or the space is divided into several functional zones.

The content of the article

Varieties of ceiling cladding

At the moment, there are two options for finishing the ceiling surface:

- Cladding ceilings without rel.

- Ceiling lining with rel.

Note. What is rel? This is the distance between the inner surface of the ceiling and the floor slab. Basically, suspended ceilings are mounted with rel.

How is the ceiling lining

Ceiling cladding begins with surface preparation.

A number of such works are carried out:

- Surface cleansing.

- Alignment.

- Padding.

What you need to know:

- There is a certain snip for such work, which regulates the sequence of all construction work.

- For different ceilings, there are rules and regulations. If the ceiling cladding is performed by suspended structures, then the preparation of the ceiling also includes installation of the structure for attaching the coating.

- We can say that SNiP is an instruction according to which a certain sequence of repair work is performed on a given surface.

Tip. All advice and established rules in SNiP must be strictly observed so that the finish is of high quality and durable.

What materials are used to decorate the ceiling

At the moment, the ceiling lining can be done using any modern finishing materials. Suspended and suspended structures are very popular.

These include:

- The use of drywall of various types.

- The use of plastic.

- Fabric and film coatings and other materials.

It cannot be said the better it is to finish and clad the ceiling, since each one, when choosing a particular coating, focuses only on his needs and financial capabilities. All claddings of this type are good in their own way and differ in the design of their surface.

Choosing a ceiling surface depending on the type of room

There are some restrictions on the use of certain cladding materials in the rooms. What are the ceilings in the kitchen area or in the bedroom, sanitary room or living room?

So:

- The choice in this case depends on the functionality of the room and on what percentage of humidity in the room, whether there are sharp temperature fluctuations. All this affects the life of the ceiling.

- For example, in a bathroom or kitchen, it is best to use plastic or film ceilings, as they are resistant to moisture and quite easily cleaned.

In the living room or bedroom, the ceiling surface can be decorated with a fabric stretch ceiling or simply plastered. In such rooms there will not be too much accumulation of dirt.

Drywall for ceilings

Very often, the cladding of suspended ceilings is done with sheets of drywall. For this, there is a certain kind of it - ceiling.Due to the versatility of the material, multi-level structures are created on the ceiling that are combined with other ceiling coatings, for example, stretch ceilings.

GKL ceiling has excellent properties. What it is?

- GCR - sheets of the same drywall, which have certain properties. GCR sheets are gray in color and have a blue marking on them. This material is used in almost any room.

There are also such types:

- GKLV - waterproof drywall.

- GKLO - fire-resistant drywall.

- GKLVO - drywall, which has fire resistance and moisture resistance.

Tip. Facing the ceiling hl can be performed by any of the above types. All of them have the same technical specifications.

Cladding GKL ceilings can be performed in two ways:

- Based on the frame (with rel.).

- Without him.

Let's consider in more detail:

- It all depends on the desired surface design. If you need to make multi-level structures on the ceiling, then profile frames are used for this.

- If the ceiling needs to be simply leveled and it does not have too large defects on its rough surface, then it can be mounted without a frame.

- Most often, preference is given to the frame method of attaching drywall sheets.

Tip. In order to accurately calculate the required amount of the main and auxiliary material, an estimate is made for the facing of the GKL ceilings.

How to estimate material consumption

If it was decided to make the ceiling surface using drywall and the structure itself will be in several levels, then it is necessary to sketch out a sketch of the future ceiling on the draft ceiling. This can be done using roulette, pencil, building level, patterns, stencils and other devices.

So:

- The room is fully measured and all work of this type should be carried out on the ceiling, as in some houses there is a size mismatch at the bottom and top of the room. Thanks to the data obtained, the quadrature is calculated.

- Next, the type of drywall is selected and its dimensions are set. Focusing on them, the necessary amount of material is calculated.

The estimate includes:

- The number of sheets of drywall.

- The number of profiles (rack and rail).

- Putty.

- Self-tapping screws and dowels and other expenses as necessary.

Note. All measurements of the premises and the calculation of the necessary material are done with their own hands, since there is nothing complicated in them.

Benefits of Drywall Ceiling Finishes

Facing for plasterboard ceiling used for many years. All this is due to the properties and characteristics of the drywall itself.

Functions and properties of drywall finish:

- Environmentally friendly, which can even be used to design children's rooms.

- Easily perceives any finishing options.

- Durable, since very often you can find a plasterboard ceiling with a large ceiling or several decorative lighting fixtures.

- Practical, as it is quite fast and simple.

- Sound absorbing, due to the structure of the material, which is not able to conduct sounds.

- Heat insulating. For this reason, it will be possible not to perform the insulation of the ceiling surface.

Tip. On the surface of drywall, you can use any number of lighting devices. The most important thing is to make the wiring and connection correctly.

To do this, it is best to seek help from a specialist in this field. There is a certain technology for performing work. Only professionals know her. It is necessary to lay the wiring before installing plasterboard sheets.

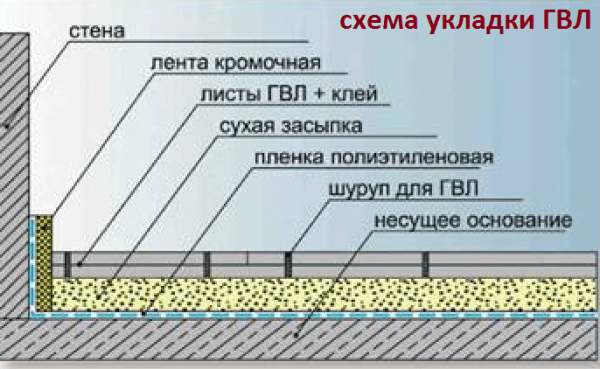

What is GVL?

We can say that GVL is one of the types of drywall, only other materials other than gypsum dough and sheets of pressed cardboard are used in its production.

So:

- GVL is a gypsum-fiber material that is produced in sheets and in its appearance is quite similar to drywall.

It has excellent features. It does not burn and is already initially resistant to the effects of climate or moisture. - Its installation can be carried out only on the frame, since any moisture ingress on the inner side of the material can eventually serve as a deformation of the ceiling finish.

Tip. When using such material on the ceiling surface, it is better to carry out insulation work using polystyrene or polystyrene foam. You can apply others.

- The lining of the ceiling gvl finishing can be performed by any materials, but, most often use liquid wallpaper or decorative plaster.

- This material also has certain types that have increased fire resistance or moisture resistance. There are also mixed types that are versatile and can be used in any room.

Tip. Fire-resistant types of material are best used in rooms where there are a very large number of lighting devices, the wiring of which from improper connection is capable of fire.

Ceiling finish plastic

This material has been used to finish the surface of the ceiling for a long time. It is very practical and durable.

It does not absorb moisture and is not able to respond to weather and climate events if used outdoors.

Characteristics:

- Plastic is off.

- It tolerates both low and high temperature conditions.

There are two types of such finishing material that are very widely used at the moment:

- Panels having different sizes and shapes, surface design.

- Lining, which is the most common version of plastic.

- The price of the material is very low, which makes it possible to use for decoration of any room.

The photo shows examples of the design of the ceiling surface using plastic.

Installation of plastic on the ceiling

Plastic on the ceiling surface is one of the materials for suspended structures. For this reason, the lining of the ceilings with lining is performed only on the prepared surface.

Stages of work:

- During preparation, the surface is not only cleaned, but also a crate of wooden planks of the same diameter is mounted on it.

Tip. If you want to make insulation or insulation of the ceiling surface, it is best to perform this type of work after installing the crate, but before installing the plastic itself.

- For insulation, foam or polyurethane foam is also used. Their thickness should correspond to the diameter of the wooden planks that are involved in the crate.

Insulation sheets are inserted into cells whose width should not be less than 40 cm.

The installation of a plastic lining on the surface of the lathing can be seen in the video.