Panel Ceiling: Material and Finish

At the moment, paneling of the ceiling has become very popular. This is due to the attractive appearance of the material itself and the simplicity of its installation.

The content of the article

Varieties of ceiling panels

Panels for ceiling lining can be made of:

- MDF.

- PVC

- Glass.

- Drywall.

- Styrofoam.

- Aluminum

Material Details:

- Mostly used panels for wall cladding and ceilings. And on that, and on that surface, the installation of the material is carried out in a similar way.

- Lining the ceiling and walls with panels can be made of moisture-proof and soundproof materials. There are also LED panels that are used to design entertainment venues.

MDF panels for ceiling decoration

Ceiling cladding MDF paneling has several advantages. It is very practical and the surface of the material does not require special care.

Also, the exterior design of the panels resembles the structure of wood. There is a very large color gamut of panels.

They can be used not only to decorate the ceiling surface, but also the wall. Cladding of walls and ceilings with MDF panels creates a holistic interior, and installation is carried out similarly.

MDF panels:

- Durable, as they can withstand quite significant physical and mechanical stresses.

- Practical and durable.

- Moisture-resistant, as their surface is reliably protected by a special tool that can give the surface a shine.

- Long-lasting, as they have a very long life. It is at least 10 years old.

- In their manufacture, means are used to increase the fire resistance of the material, but the wood itself, which is used for MDF panels, freely perceives the effects of fire.

- The surface of the panels can be matte or glossy. It is found in most cases only to be smooth, since a structural or embossed surface can only be made using special equipment and costs the material several times more expensive than usual.

Dimensions and shapes of MDF panels can be:

- Square.

- Rectangular.

- In the form of wide or narrow stripes.

Installation of the material is quite simple, only preparatory work is carried out on the surface.

Tip. To give the room a twist and shape it unusually, you can use not one shade of material, but several. Of the panels, decorative panels are often laid out on the ceiling.

Installation of MDF panels on the ceiling surface

In order to mount this type of ceiling coating on the surface, the crate is originally made.

Tip. Before such work, the ceiling is cleaned and paint or plaster that has already moved away from the surface is removed.

This can be done with spatulas or special flushing agents.

The lath for fastening the panels can be:

- Metal.

- Wooden.

Let's consider in more detail:

- For metal crates, profiles are used that do not have a large mass, but are very strong and reliable.If a wooden crate is used, then wooden planks of the same diameter are used in it, which will create a flat ceiling surface after installation of the material.

- Metal and wooden crates are fixed to the ceiling with dowels. To do this, you can use a hammer or drill.

Tip. The cells of the crate, both metal and wooden, must have the dimensions of the panels themselves so that they can be installed quickly and efficiently.

- Also, during the installation of the material, it is possible to carry out insulation and insulation work. Use for this foam or expanded polystyrene in the seams.

Due to the relative strength of these materials, they are tightly inserted into the cells of the crate, and only then MDF panels are mounted.

To install the material you will need:

- Screwdriver and screws.

- Construction level and tape measure.

- Jigsaw.

Each panel is screwed tightly against each other to the crate. It should be borne in mind that the jigsaw can not provide an even and high-quality cut of the material and for this reason a grinder is used to file the panels.

Note. Cladding of walls and ceilings with MDF panels is performed efficiently if the crate is made on the surface in compliance with all norms and standards.

PVC panels for ceiling cladding

The most practical and most affordable panel ceiling lining PVC The surface of such a material does not require special care, as it is resistant to various influences.

Plastic:

- Moisture-proof and durable.

- Does not respond to the effects of temperature fluctuations.

- Flame retardant, since under the influence of fire it does not ignite, and can only melt and at the same time not emit harmful substances.

- It tolerates low and high temperatures and does not absorb dirt.

So:

- All this makes it possible to use plastic panels to decorate any room with any temperature and humidity.

- Lining the ceilings with PVC panels can be very original, as there is a large assortment of color schemes for the surface of the material. The surface itself can be flat or embossed, matte or glossy.

Tip. It is not recommended to use glossy PVC panels for finishing the kitchen area, since fat deposits on them will be immediately noticeable.

- You can clean the material using any means, only without the use of metal brushes, which can damage the surface of the panels.

- Lining the ceiling with pvc panels can be performed using decorative lighting fixtures, the electrical wiring for which is laid after the manufacture of the lathing.

Plastic panels can be square, rectangular or in the form of a plastic lining. All types of panels of this type are mounted according to a similar principle.

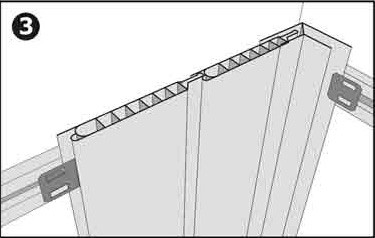

Installation of PVC panels

Lining the ceiling with PVC panels is performed in the same way as the installation of MDV panels. Also on the surface you need to make a crate and most often for plastic it is made of wooden planks.

Tip. Since wood is very susceptible to moisture and temperature extremes, the surface of the frame should be varnished or painted after its manufacture to protect it from such influences and thereby increase the life of the finish.

Also, each joint of the plastic panel must be treated with sealant so that moisture does not get under the finish.

To install PVC panels you will need:

- Starting strip for the initial installation of the material.

- A construction stapler that will securely fasten each decoration element to the crate.

- Construction level for smooth and high-quality installation of material.

- The screws that secure the starting strip.

- Screwdriver for using self-tapping screws.

- Grinder for cutting material.

The video shows an example of the installation of PVC panels on the ceiling surface.

Glass ceiling panels

The use of glass ceiling panels has recently become used for office space. This type of material on the surface of the ceiling looks very original and unusual.

So:

- Used for the manufacture of glass ceiling panels. Tempered glass of large thickness.

- The main advantage of these panels will be that under them you can use any number of lighting devices that are placed directly on the rough surface of the ceiling. This design of the room looks very unusual.

The price of such a finishing material is quite high. The panels are very practical and durable. Even in the event of a breakdown of any trim element, it is easily replaced.

The panels are moisture resistant and do not burn. Freely tolerate high and low temperature conditions. Panels can be rectangular or square.

Installation of glass ceiling panels

For the installation of such material there is a special instruction according to which all actions are performed to make such a ceiling coating safe for use.

Work:

- In the course of work, special profiles are used, which are mounted on the surface using dowels. On their front side, they have trims that hold the glass panels on the frame.

- Despite this, all the work is quite light and do it yourself.

Tip. To securely fasten glass panels to the surface of the profile frame, liquid nails or a high-strength sealant are used.

Plasterboard panels for ceiling cladding

The lining of the ceiling panels, which are made of drywall in popularity, is in second place after the plastic ceiling panels. The plasterboard material itself is intended for leveling the surface.

More details:

- Also, multilevel structures on the ceiling are built from it. The surface of the drywall is flat and can be decorated using any modern finishing material.

- Drywall is mounted on a profile metal frame, which is built on the ceiling surface using special profiles. They are mounted to the ceiling using dowels, which allow you to securely fasten the structure. Between themselves they are fastened with screws.

Tip. For rooms that have high humidity, moisture-resistant drywall panels should be used.

On the ceiling, you can install an unlimited number of lighting fixtures that will decorate the surface or divide the room into zones.

Also did in a similar way. Tired of the whitewashed ceiling, I decided to do something modern with built-in spotlights. First of all, the low cost of such a ceiling and the opportunity to make it with your own hands attracted. If the installation work is done slowly and carefully, the result is more than good, the ceiling is smooth and beautiful.The only thing here is to choose prettier panels so that they fit the general interior of the rooms. In my opinion, such ceilings are an excellent alternative to suspended ceilings, which are very expensive and which it is extremely difficult to pull on your own!