Exterior facing of the building: materials and technologies

The outer cladding of structures of buildings and structures, protects their surface from weathering, and significantly extends the service life. The materials used for the decoration of facades are subject to special requirements: strength; resistance to low temperatures, humidity and ultraviolet; ease of installation and low weight.

The last two points are especially relevant when it comes to multi-story buildings. Of great importance is the aesthetic component. The excellent appearance and properties of many materials are such that with their help, cladding is often performed inside the building and outside.

The content of the article

Materials for curtain walls

As technology advances, manufacturers offer for facades many new developments. But there are a lot of materials that were created decades ago, which not only did not lose their positions in the construction market, but also significantly strengthened them.

Many materials can be attributed to them, with the help of which a ventilated cladding of the building is created.

We will talk about the details of such exterior wall decoration a bit later. In the meantime, we present to you a brief overview of modern finishing materials used in ventilated facade systems.

They are united by a similar installation method, namely: installation building cladding on the supporting frame.

| Name and appearance of the material | a brief description of | Sizes and approximate cost |

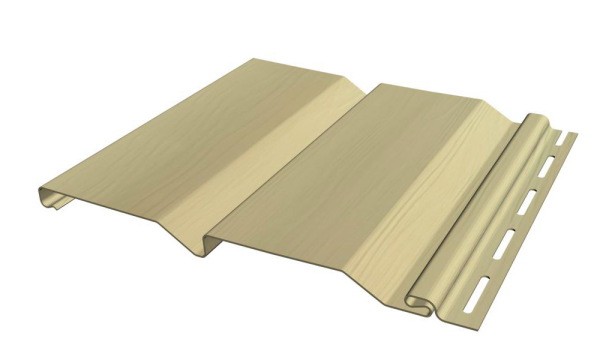

This material is a long panel with a lock connection. Various types of siding are produced: aluminum, steel with polymer coating, vinyl, fiber cement, wood, plastic.

Using this material, the cladding of old buildings, for example, five-story buildings of Soviet construction, requiring major repairs, is often performed. | This material does not have a clear dimensional standard; they can vary from different manufacturers.

Its price is -150 rubles apiece. The cost of the panel depends not only on its usable area, but also on the feedstock used in production. | |

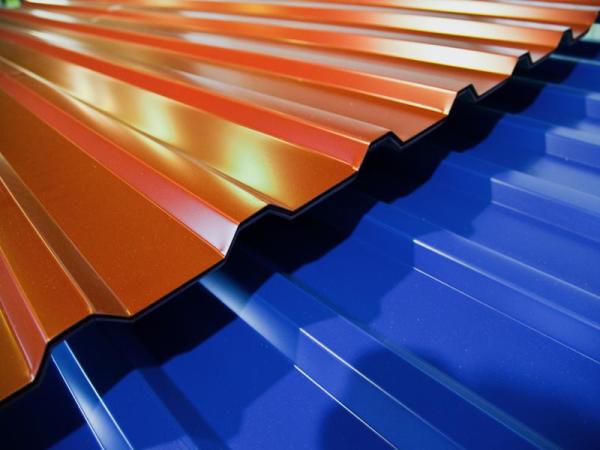

The material is a steel profiled sheet, galvanized and painted, or having a polymer coating. It is classified as intended for wall flooring, roofing and load-bearing.

It has strength, absolute moisture resistance, and has excellent performance characteristics. Most often used for facing industrial buildings. | The width of the profiled sheet is usually in the range of 1000-1150 mm, the thickness is 0.4-0.8 mm. The length, depending on the destination, can vary up to 12 meters. The average price of the material is 165 rubles / m2. | |

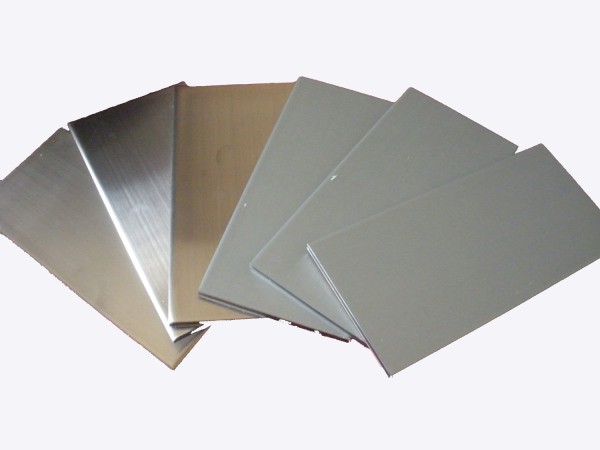

Alucobond composite material is a multi-layer long panels designed for external cladding in the system ventilated facades. Most often, with his participation, the outer lining of industrial buildings, office and shopping centers.

Due to these qualities, composite panels also cladding the internal walls of the building. Such decoration can be seen at airports, sports facilities, exhibition halls, and covered markets. The material allows installation without the use of insulation. | Alucobond standard size is 2440 * 1220 mm, width varies from 2 to 6 mm. The most used colors: silver, smoky, bronze, metallic. But there are at least fifteen different shades on sale. The square meter of the panel weighs no more than 8 kg.

Universal panel - 1600 rub / m2 Refractory panel - 2200 rub./ m2

| |

The combination of the properties of polymer resins and wood in one product can be considered the most successful embodiment of all the requirements for materials for exterior decoration.

Moreover, the material acquires the appearance of a tree and the operational properties of polymers. And these properties allow products not to be afraid of moisture, ultraviolet radiation, temperature changes.

It could be exterior wall decoration, as well as cladding inside the buildings, made in the style of fachwerk or country. | Most often, this material is available in the form of boards in the size of 6000 * 120 * 25 mm, or 3000 * 140 * 22 mm, there are terrace options, there is a floor covering in the form of a parquet board, and there is a facade board. Their cost varies within 220 -270 rubles / m.

| |

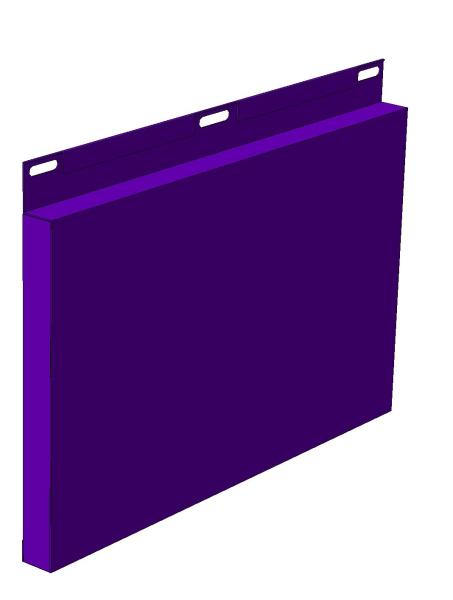

Front cartridges are made of galvanized steel with a thickness of 0.5-1.2 mm, have a polymer or powder coating. Their distinctive feature is the volumetric configuration, obtained by bending the edges from four sides.

Front cartridges are designed for facing industrial, administrative and residential buildings, including multi-storey buildings. During installation, SNiP for building cladding is always taken into account (SNiP 2.08.01-89 and SNiP 2.08.02-89). Ideal for decorating buildings with the right geometry. | The price range per square meter is very large from 550 to 1450 rubles. This depends on the quality and thickness of the metal, as well as the complexity of its decorative coating. The price usually includes elements of a metal frame. | |

Porcelain tile is an artificial stone, but it contains only natural ingredients: clay, sand, feldspar. The raw material mass is pressed under high pressure, and an unusually strong material is obtained, with almost zero water absorption.

It can be mounted not only by the adhesive method, but also on the frame, using hidden fasteners. Most often used for decoration of office and public buildings. | For facade cladding, tiles of size 30 * 30 are used; 60 * 60 and 120 * 80 cm. Prices in the range of 450-650 rubles / m2 | |

Thermal panel, this is a symbiosis of insulation and finishing material - such a kind of composite. The most valuable thing is that the front side does not imitate, but consists of natural materials: clinker or stone tiles, marble chips. For ease of installation, additional and corner elements are produced.

The technology for facing buildings with thermal panels is quite simple, it does not require additional insulation of the facade, and the frame can be installed not metal, but wooden. | The size of the ordinary panel is 1000 * 650 mm, the thickness of the insulation can be different: 90.80.60 mm. Depending on the decorative coating and thickness, the price varies from 1600-2900 rubles / m2 |

So:

- This is not a complete list of materials that can be used for mounting a curtain wall. There are various variations of facade stone made from stone chips, white cement and dyes.

With the help of decorative stone, which can have any configuration you want, various design compositions are created for the exterior walls of buildings. - The front stone is mounted by analogy with porcelain tile. Typically, an order is placed at the factory for the production of such material, and the cladding is done according to the design documentation.

In the photo at the beginning of the article you see the facades of multi-storey residential buildings, lined in this way. In the picture below - a wonderful facade of the sports complex.

Facing Features

Features of frame cladding

There are other, equally popular materials used to create mounted ventilated systems. Front panels alone can count at least a dozen species.

And also a board from a natural tree: block house, imitation of a bar, planken. All of them are mounted using the same technology, with slight differences that are associated with the dimensions of the materials, as well as the features of their joints and locks.

So:

- Some differences may be associated with structural solutions of buildings. For example, the cladding of monolithic buildings is somewhat different from the technology for wall decoration. frame house. Although, systems of ventilated facades are used in both cases.

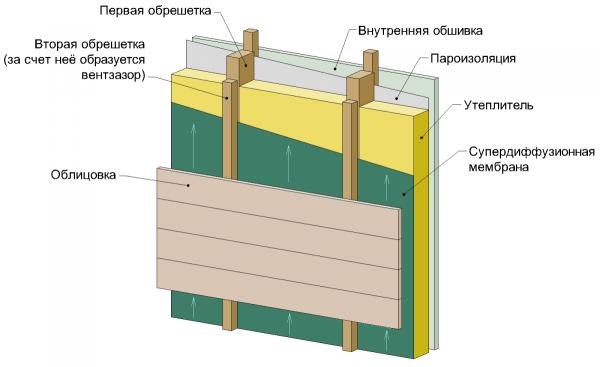

- Their essence is that there should be a gap of at least 3 cm between the casing and the supporting wall. It provides free air circulation, preventing condensation from accumulating.

In non-insulated systems, this gap is provided by the thickness of the profile. But, ventilated facades can also be insulated. - In such cases, the profile is mounted on brackets that provide the necessary indentation: both for placement of insulation, and for ventilation clearance. In frame-panel wooden buildings, the clearance is provided by the thickness of the counter-rails fixing the windproof membrane.

- If there is no need for the installation of insulation, the list of work performed is as follows: a coating of waterproofing walls is carried out, a frame is installed, and a decorative coating is hung. In the case of insulation, the heat insulation tab is added to the list of technological operations in the cells of the crate, and the installation of a vapor barrier film if unfused mineral wool or polystyrene was used.

- Most facade materials can be purchased as a set from the manufacturer. You will be offered everything you need to work: usually these are three types of profiles with different sections, bearing brackets, fasteners.

Insulation and membranes are selected by the buyer at his discretion. The installation manual is attached to the kit, which will allow you to assemble the frame with your own hands without any problems.If something is not clear, you can always watch the video.

Frameless ventilated facade

There is another material that is used to create ventilated facades - a facing brick. He did not get into our table, since the technology of its installation is fundamentally different from the frame systems that we talked about above.

So:

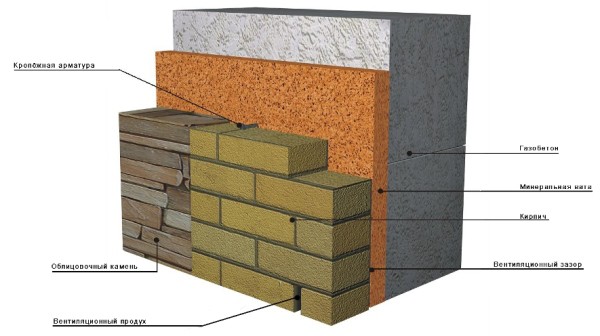

- Since the brick, in comparison with other materials, has a fairly solid weight, it is mounted with the foundation on it and is firmly connected to the supporting wall by anchors. The so-called well laying is carried out.

- Such decoration is most often done during the construction process, but it may well be the facing of an old house that is subject to major repairs. In this case, it is necessary to carry out laborious preparatory work, which consists in digging the foundation in order to find out its width.

- If this is a strip foundation, then for brick cladding without insulation, it is necessary that it has at least 12 cm of free space. Then you can arrange the brick with the necessary clearance, and its edge will hang down by 3 cm - this is allowed by building standards.

- Let's say there is not enough space for laying the brick, or the foundation has a columnar or pile structure, and there is no support for the masonry at all.

In this case, before making the cladding of the building, it will be necessary to fill in the shallow strip foundation along the perimeter of the existing foundation. Only after a full set of concrete strength, it will be possible to proceed with the construction of a decorative wall. - If the walls will be insulated, when topping up, the thickness of the insulating material must also be taken into account. You may wonder how the structure is ventilated, because the brick cladding is tight? For free access of air in the lower rows of the masonry leave seams that are not filled with mortar - air. In the diagram above, this is clearly visible.

Consider yourself lucky if the foundation of the old house is above the zero mark and has a protruding part (mound). Then the brick cladding can rely on it, and you will save time and money.

This is only possible if the width of the blockage is not less than 15 cm (12 cm brick width + 3 cm gap). Such a distance is necessary so that the brick wall does not hang down, otherwise it will be ugly.

So choose the material that will fit into your budget, and go for it - design your home or office to the delight of yourself and its inhabitants!