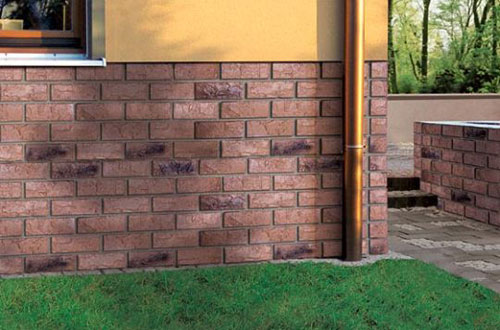

Facing the basement of the house with basement siding

Facing for the basement of the house is extremely important. This finish saves heat and prevents the penetration of dampness into the room.

It extends the life of the whole building. Facing the basement of a wooden house with basement siding is quite common in everyday life.

Although he recently appeared on the sales market. In this article we will consider this issue.

Instructions will be given on the rules for completing this work.

The content of the article

Advantages and disadvantages

Cladding basement houses can be carried out by quite different materials. Therefore, before making a purchase, you must fully weigh the pros and cons of this material.

And only after that make a purchasing decision.

It is worth watching photos and videos on this topic, to collect more information:

- The price of the material is not so high, almost anyone can afford it;

- Such a finish perfectly tolerates temperature changes and high humidity and will reliably protect the structure;

- The weight of the material allows its installation without additional foundation and this will significantly reduce costs;

- All work can be completely done with your own hands and without outside help, and this will significantly reduce the cost of the entire structure;

- When attaching the frame, insulation can be made, and the thickness of the insulation can be applied to almost any;

- This material is quite durable and will last for many years;

- When performing such a finish, you will not need to do a full finish on the base plane. It can only be limited to basic training.

The material itself is already facing. After installation, you do not need to do the final finish.

Attention: there is one drawback, plastic becomes quite fragile at low temperatures. Therefore, work is best done at a positive temperature.

Finishing the basement of the house

Base trim a country house is done according to certain rules and in compliance with technology. There are no trifles. Each work must be carried out efficiently.

Follow the correct layout. Otherwise, the entire configuration will have an irregular geometric shape.

Surface preparation and marking

Quite a lot depends on the quality of the preparation of the base plane, this is the correctness of the subsequent work and durability.

This is the beginning of work and we need to do everything right:

- First you need to remove everything that interferes. These are all protruding objects;

- After that we do inspection of the plane. We are not particularly interested in bumps. We look at the exfoliation of the old material.

If they are, then it is necessary to eliminate this matter. To do this, use a hammer and chisel; - Now we have to apply a primer to the surface. Preference should be given to deep penetration liquids;

- Now we need to correctly determine the beginning of the fastening of the finish. Determine the start of the beginning of fastening.

After that, we need to make a straight line that will be completely parallel to the ground. This largely determines the correct geometric shape. Put a mark on the plane; - Now we should transfer this mark to other surfaces. To do this, use the hydraulic level.

It is in retail and must be purchased in advance. Or you can do it perfectly yourself.

It is this tool that allows us to do this work most accurately. Move the mark to other walls; - Now we need to connect it all in one line. To do this, use kapron thread and beat off the desired size.Now we have the installation start line;

- Now we need to identify the upper edge of the fastening of the trim parts. To do this, make a mark and do all the work as described above;

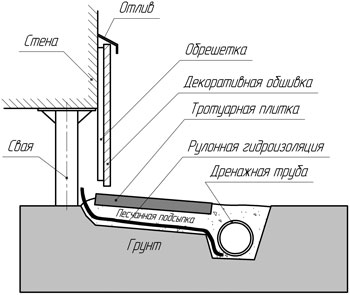

Attention: I want to say about the upper line of fastening. It should be ten cm above the floor.

Otherwise, your dew point will shift and condensation will accumulate. This is done if you are finishing the basement, but the walls are left uncoated.

If you also use wall decoration, then at the junction of these planes you will need to do everything completely hermetically, otherwise moisture will penetrate the room.

Frame installation

Cladding country house the base is placed on the frame. The correctness of the geometric shape and the durability of the design depend on the correctness of the work.

The material of manufacture may be a metal corner, which is the most durable, but you can also use a wooden beam. It all depends on the desire of the owner.

Attention: if you chose the second option, then you should first do the treatment of timber with antiseptics, which are available on the market. This will significantly extend the life of the structure. Only this should be done in advance.

So:

- We cut the slats in the desired size and make the lower harness. For fixing we use the expansion bolt shield. First we make a hole with a punch and after that we make the connection;

Attention: The frame has its own ches and therefore its fastening must be rigid. Therefore, do not use the wall plugs from the kits.

Buy separately the plastic and the screws to it, which should be taken a couple of mm more from the hole section. Then everything will be securely fixed.

- After the lower strapping is completed, the bars should be fastened along the upper contour. We do as described above;

- Now we need to fix the transverse rails. To do this, we need to determine the installation level.

It should be in one plane. To do this, we need to pull the fishing line along the diagonals of the basement trim. Then we will have a reference to the height of the installation;

Attention: For the frame, the thickness of the insulation should also be determined. According to this, the mounting height of the frame is selected.

Remember, the material should not be deformed by the panels. Otherwise, it will lose its properties.

The fastener should be tight, but do not press it down. Provide a clearance of a couple. Then there will be normal ventilation, which will not allow condensation to accumulate.

- We make markings for the fastening of the rails. For this, the size of the insulation mats should be taken into account, but the distance between them should not be more than 70 cm;

- We cut the slats in size and fasten to the dowels;

- Now we need to put a layer of insulation on the plane. To do this, we cut it to size and fasten using a construction stapler.

There is one point. When joining the film, this should not be done back to back, it is necessary to overlap about 10 cm. When attaching to the rail, you also need to wrap the material on the rail for a couple of cm.

Make sure that it is distributed evenly and does not puff; - After that, you can fix and insulation. To do this, we use building fungi. They are made of plastic.

To make the connection, first make a hole with a perforator and then drive in the fungus. For one mate, a connection is made of at least six points.

Panel Installation

We make the basement of the house, the lining is mounted on a flat frame and all work is performed according to the following rules:

- To begin with, we fasten the starting support strip. For fastening we use self-tapping screws.

When placing we use the building level. We need to do everything for sure. Mounting points do not less than 30 cm;

Attention: All additional elements are on sale and they have a rather low price. Do not take it close.

At least about 15% will go to waste. Therefore, do not save on this.And yet, every joint, this is an opportunity for water to penetrate. Remember this.

- Now the corner bar is attached to the corner. Before this, it should be tried on and cut to the desired size, after which the connection is done on the screws.

There are several types of angles. You’d better get it under the name “complex angle”, this element is the easiest to use and you can attach other details to it from almost any angle; - Now we begin to fasten the panel to the start bar, which we insert into the groove of the start panel. After that, we move it to the corner panel.

Only it should not be pushed as far as it will go, provide a one-cm gap, this will save you from troubles during temperature changes. If you do the work during the hot season, then the clearance should be reduced; - After fastening in the groove, the panel should be screwed. For this, self-tapping screws are used.

The connection is made only through the provided groove in the panel. Mounting is performed in the center of the groove.

Never fully tighten a self-tapping screw. A gap of a couple of mm should be left; - Next, we mount the next panel. This is done as in the first case;

- Every item base trim must be attached at least five points. Watch, self-tapping screws must enter strictly at an angle of 90 *;

Attention: Panels with temperature differences change in size by six mm. Therefore, take this into account and be guided by the time of year.

- This is how to finish the entire plane. When attaching the last panel, it will have to be cut in length.

To do this, you must first try on and then make an incision with a hacksaw with a small tooth. After that, we do the fastening and do the installation of the angle bar, which will cover the errors; - The top cut should cover the finish bar. This element can be used for further decoration of the building with siding.

Now it’s clear that the work is not so difficult. Just for its implementation, you should correctly markup and do not rush.