Base cladding technology and application of materials

The technological map for facing the plinth can be using any modern finishing material.

The base is of great importance to the structure. For this reason, quality finishes are important.

The content of the article

The functions of the cap and its variations

A basement for any building is very important. It helps to keep warm. It has a certain height, which is at least 30 cm.

There are three types of cap:

- The speaker.

- The dropping down.

- Uniform.

- It is being built from a brick of a certain type - red refractory.

Tip. The most practical and long-lasting design option for the basement is the sunken one, since it is reliably protected by the wall of the building.

It is possible to use any finishing materials on it, since they will not be so effectively affected by weather and climatic phenomena.

Basement insulation and decoration

Insulation technology and plinth trim may have several options for performing work. All this depends on the selected finishing material.

Work:

- Insulation of the structure is carried out inside and out. For internal insulation work, expanded clay or dry algae is used.

They are used on the rough floor, and only then is a wooden frame made, on which concrete is poured.

Tip. To make the floor inside the building warmer, there is a “warm floor” system, which is also widely used for space heating.

- It is very economical and the degree of heating of the room is quite high.

Outside the base is insulated:

- Extruded polystyrene foam.

- Styrofoam.

- Polyurethane foam.

- Mineral wool.

So:

- It is worth considering that mineral wool after a certain period of time may lose its properties due to the influence of temperature changes and climatic conditions. It is because of this that it is not so often used in external insulation.

Tip. It will be mandatory to mount OSB sheets, plywood or moisture-proof drywall on the surface of the insulation.

Only then can it be easily fixed to the surface of the finishing materials.

Varieties of materials that are used to decorate the base

The technology of facing socles can be performed:

- Natural agglomerate.

- Artificial stone.

- Tile "Besser".

- Porcelain stoneware.

- Siding and plastic.

- Decking.

See photos of this design of the basement.

Natural and artificial stone in the lining of the basement

The technology of facing the socle with natural stone and artificial is similar in principle to the execution of work.

The properties of materials are also almost identical, they are:

- Moisture resistant and practical.

- Durable and wear resistant.

- Fire and frost resistant.

- Freely tolerate any temperature conditions (both high and low).

- Their strength is different, since the natural agglomerate has a very dense structure, which gives strength to the material. It is also worth considering that the price of natural stone is quite high.

Natural stone is environmentally friendly.

The most commonly used finishes are:

- Shell rock.

- Onyx.

- Marble or granite.

- Sandstone.

- Basalt and so on.

Note. A decorative stone may have imitations of natural agglomerate on its surface.

It is made from:

- Acrylic

- Gypsum dough.

- Synthetic substances.

Which is better: natural or artificial stone

Materials are similar in their properties. Base trim only natural stone the technology is different.

It depends on the weight of the agglomerate, which in most cases is quite large. For this reason, the surface of the base is previously strengthened.

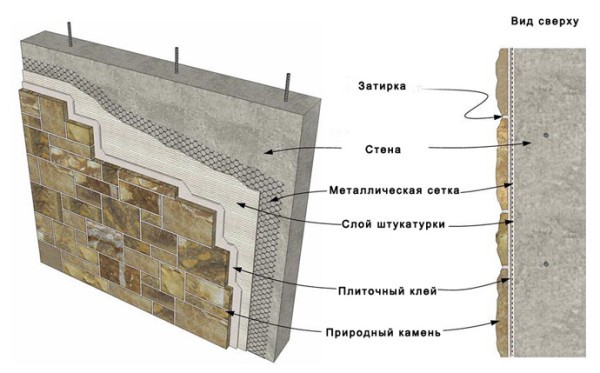

To do this, use:

- Strong construction nets.

- Wire mesh.

Note. The use of natural stone will be several times more expensive than artificial.

Installation of natural stone

Facing the basement with natural stone implies the technology of such work:

- Surface reinforcement.

- Her alignment.

- Padding.

So:

- Initially, grids for reinforcement are mounted on the surface using special mounts. They are already superimposed with a solution of concrete or plaster, which is intended for external finishing work.

- Once the solutions dry on the surface, it is treated with a primer. Use rollers or brushes for this.

The principle of applying the product is similar to applying paint.

The technology of facing the base with natural stone has two ways of installing the material:

- Using special glue of increased strength.

- Mortar concrete.

The glue should be of a certain consistency and for this there is a description and instruction on the box of the product. According to these descriptions, liquid and various agents are added to the solution.

The installation of natural agglomerate is similar to the installation of ceramic tiles. Only during the work, cruciform lighthouses are not used.

Decorative stone mounts

Facing the basement with stone the technology does not provide for surface strengthening, since the material does not have a large mass.

Surface preparatory work can only consist of:

- Alignment.

- Priming.

- To level the surface, you can use concrete mortar or plaster.

Both this and that remedy are applied using:

- Spatulas of various sizes.

- Building level.

- Sandpaper.

More details:

- As a rule, two types of plaster are used in the work: “start” and “finish”. In leveling the surface, the last type of tool can not be used, as it helps to smooth out defects in the starting layer of plaster.

- For mounting the material on the surface, the stone facing technology of the basement involves the use of a solution of concrete or special glue. The work is similar to the installation of natural sinter.

Tile "Besser" in the finish of the basement

Using Besser tiles, the plinth cladding technology is very similar to the use of ceramics and porcelain stoneware.

Material is made from:

- Coarse peeled sand.

- Sand.

- The crumbs of natural agglomerate (basalt, granite, shell rock, and so on).

- The tile has excellent technical properties and characteristics. It is very strong and durable.

- She does not perceive the effects of moisture and dirt. The tile does not burn and does not deform under the influence of high and low temperature conditions.

The surface of the tile may be:

- Smooth or rough.

- Glazed, polished, matte.

- Structural or embossed.

Material Specifications:

- It has imitations of any modern finishing material. Recently imitation of bricklaying has become very popular.

There are also other types of surface finishes. - The size of the material is also varied. There are standard parameters that are similar to the size of ceramic tiles.

All other sizes can be made to order.

The finish of the basement of the Besser looks quite interesting and unusual. There are blocks of such material, which are mounted on the basis of brick mounting.

The life of the finish can be at least 20-25 years.

Installation of tiles "Besser"

Facing the base with tile technology can be both with insulation work, and without them. The surface must be flat, as the back is also flat.

So:

- The surface is leveled with plaster. It is not required to use a cement mortar, since the weight of the tile is quite small.

The solution is applied in several layers to the surface with a spatula. Each layer is treated with sandpaper with large cells after the solution dries. - The installation of "Besser" itself is quite simple and the whole process can be done with your own hands.

Tip. You need to install this type of tile using an adhesive mortar, which is designed specifically for this or concrete mortar with various additives to increase its strength.

- To cut tiles, you need a tile cutter with special nozzles for cutting non-ceramic tiles. This is due to the fact that the main part of the material is sand.

- You will also need a building level that will help to make the finish smooth and of high quality.

Tip. To start facing the base with the use of tiles, you need to from the bottom of the structure.

The first row is immediately mounted and only after its reliable fastening can one already proceed to the installation of subsequent rows. To mask the masonry joints, color decorative putty is used.

Porcelain stoneware

Porcelain tile has the same properties and characteristics as simple ceramic. Only her strength is several times higher.

This is due to the fact that in the manufacture of ceramic tiles only clay dough and various additives are used. And porcelain stoneware includes not only several grades of clay, but also feldspar, which gives a special indicator of the strength of the material.

Features:

- Tiles are single or double fired. The surface may have various designs and may be glazed or matte. There are also structural, relief and rough surfaces of porcelain stoneware.

- Installation of this type of ceramic tile is quite simple. The work includes preliminary leveling of the surface and only then installation.

Tip. For facing the plinth with porcelain stoneware in leveling the surface, the most commonly used concrete solution is resistant to weather and climatic conditions.

The material is fixed using a glutinous mortar for ceramics or concrete mortar. You will also need cruciform beacons that help to make an even distance between the porcelain tiles and colored decorative putty to mask masonry joints.