Facing the basement with siding panels

Panels for facing the basement of the house are quite different, only the most popular for today are basement siding panels. The lining of the basement with pvc panels is quite common and there are reasons for this, as we will discuss below.

You will have the opportunity to see photos and videos on this topic and decide whether such a design is suitable for you. Will be given and instructions for performing this work.

If everything is done according to the plan, then such work does not take much time and does not require much effort.

The content of the article

Advantages and disadvantages of the material

Before you make a purchase of a material, you should familiarize yourself with its qualities and only then make a decision:

- The basement cladding panel can be made of various materials, this one is made of pvc, which makes it quite durable. It perfectly tolerates temperature changes and high humidity;

- Base trim plastic panels can be made using insulation, which will significantly increase thermal insulation;

- The plastic panel for facing the base is resistant to corrosion and will last quite a long time. Durability of material at height;

- All work can be done with your own hands, which will significantly reduce the cost of the entire structure;

- Large color gamut and many textures also speak in favor of this material. You will be able to acquire facing both under a stone, and under a tree, it all depends on your desire;

- It is an environmentally friendly material that does not harm your health;

- It fully protects the basecoat from external influences and therefore extends the service life. In this version of the finish, the base simply does not even absorb moisture and this has a beneficial effect on heat transfer and saves you money on heating;

- Such a finish does not require large maintenance costs. It will be enough for you to simply wipe the surface with a rag.

So that it repels moisture and dirt, you can apply a wax coating that will serve both as a protection and add quality appearance for a long time.

Installation of basement siding

Cladding basement house pvc panels are not such a difficult job, but it should be done according to certain rules and in compliance with the technology. After all, the final result will completely depend on the correct installation.

All work is carried out in several stages, which strictly go one after another. There are no trifles, everything has its consequences.

The right tool and material

For continuous work, you will need to prepare the tool and the necessary materials:

- To get started, buy a siding. Pay attention to what temperature conditions it tolerates. Give preference to trusted brands. Do not purchase products from unknown manufacturers;

- Acquire the profile metal or wooden bars in the required volume. The latter do not forget to treat with antiseptics;

- For the correct layout, you will need a hydraulic level and a nylon thread;

- To make holes, prepare a hammer drill;

- Get the level of construction, the length of which should not be less than 1.5 meters;

- Buy a dowel, and it should be noted that the immersion of the element in the base plane must be at least 2/3 of the height of the profile or bar;

- Screwdriver;

- Hammer;

- Bulgarian.

Surface preparation and fixing the lathing

Facing the basement of the house with pvc panels begins precisely with the preparation of the base plane and the fastening of the lathing. A properly prepared surface will allow to qualitatively fix the details of the frame and if a fungus has formed it should be removed and the work done further.

Now everything is in order:

- First, do a surface inspection and remove the old coating. If there is high-quality plaster, then it can not be removed, but if there are delaminations, then they should be removed and simply beat off with a hammer and chisel;

- After that we do an inspection. We need to treat the surface with the help of antiseptics, which are available on the market.

They will treat diseases of a covering and will not allow them to develop further.

Attention: If there is no fungus on the wall, treatment should still be carried out even for prevention. If the disease manifests itself after installing the plastic, then this work will be quite difficult to do. It’s better to do it right away.

- Now we need to apply a primer to the surface, which will strengthen it. To do this, use a brush or spray.

Next, do the installation of the frame. This must be done correctly and in a certain sequence.

Facing base panels are mounted in two versions: installation can be performed on a metal frame, or made of wood. In principle, both options are acceptable, only the second is more reliable. Metal is not so susceptible to decay.

Attention: If you chose the second option, then do not forget that before installing it is necessary to treat the material with antiseptics, which will significantly extend the life of the entire structure. This should be done in advance and completely allow the material to dry.

So:

- First we need to determine the plane of attachment. The top should be completely perpendicular to the surface of the earth.

There should be a placement of panels completely parallel to the ground. This will not work out in the eye. We put at risk the start of placement on the wall;

Caution: Panels have a certain height. When you put a mark to start mounting, you should consider one circumstance; the panel should overlap the dew point.

And this is the floor level. If this is not done, then condensation can accumulate and the effect of the finish will be much lower. It is necessary to overlap the floor by 10 cm and not less.

- After determining the beginning of the fastening of the siding, we need to transfer this point to other walls, for this we should apply the hydraulic level. With its help, this work can be performed most qualitatively.

We get it at retail or you can do it yourself. We transfer the size; - Now we need to connect these points with one solid line and mark the line of the beginning of fastening, for this we should use kapron thread and just beat off the size;

- Now we cut the material to the desired size and fasten strictly along the line. Self-tapping screws are perfect for a wooden wall, if it is made of concrete or brick, then you should make a connection to the dowels.

To do this, make a hole with a puncher and after that we do the fastening. The first line should be installed at a distance of 110 mm from the edge.

Then you will have no problems installing corner elements;

Caution: The frame must be fixed firmly. So you should not use the dowels from the sets, nor will they provide reliability. Buy separately plastic and self-tapping screws to it, only they should be a couple of mm larger from the plastic section. Then we will have a pretty reliable connection.

- After installing the lower profile contour, we need to place the transverse one. Consider the size of the panels immediately.

The connection should be done only on the profile, and not on the weight. Correctly measure and mark.

All elements must be in the same plane.To do this, connect the edges of the contour diagonally.

They determine the height of the fastening of the transverse elements; - After that, we cut the material to the desired size and make the fastening in the manner described earlier. Gaskets should be used to adjust the height;

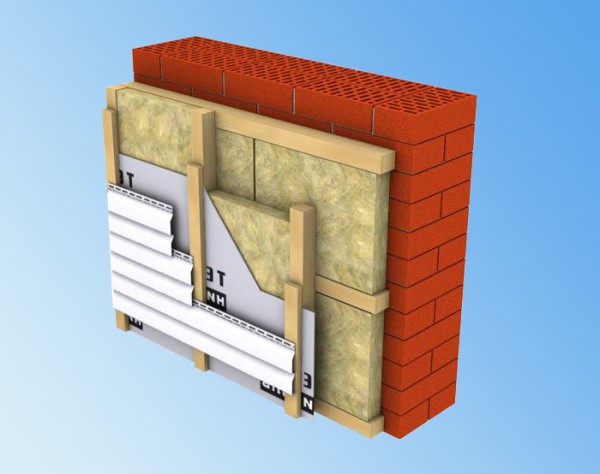

- After installing the battens, you can mount the insulation. To do this, first apply a layer of waterproofing.

We cut it and fix it. Only it does not stand fastened right up to the crate. The material should be wrapped on the profile and then make the connection; - After that, we make the installation of insulation.

Attention: When attaching the insulation, the thickness of the sheets should be taken into account. The fact is that when fastening the cladding, the material should not be deformed, otherwise it will lose its properties.

A gap of a couple should be provided. And this will be correct. Therefore, you should decide on this issue at the beginning of the installation of the frame.

Installation of basement siding

The base panels for the plinth are mounted on the frame, which must be installed according to the dimensions of the plates. Here, the facing of the front plane is already beginning and the work must be done quite accurately.

The wizards give some tips for doing this work and should be heeded:

- In the corners we fix the internal and external elements into which the panels will be inserted. We do the fastening only in the intended holes, we do not tighten it tightly. We make a play of 1-1.5 mm;

- Facing the basement with pvc panels is done only in an upright position, so do the calculation during the planning based on this;

- Fastening should begin from left to right and not otherwise. If you get more than one panel, then you should start from the bottom rad and move up.

Never start fastening the next row without finishing the first; - House cladding basement panels are made only with the use of measuring tools. Never make connections without first fitting and fitting.

At first the panel is tried on and only then fastened. When installing for testing, use the building level and square. Incorrect configuration will only spoil the appearance; - When joining panels, you should always remember about the gap, which must be. This will save you from trouble when expanding materials;

- Do not fasten fasteners tightly. Backlash should be provided.

This is useful when expanding material. If the fastening is too rigid, then this will lead to deformation during temperature extremes;

Attention:

When attaching the elements, you should worry about the penetration depth, which should be at least 12 mm. The material has its own weight and with a smaller size in the process of time, it will simply turn out the fasteners.

- Breathable materials should be used for insulation. Do not use foil;

- Each panel must be attached to at least five points;

- All fasteners must be installed strictly at an angle of 90 * and not otherwise. If the self-tapping screw did not go right, then you should not seal it in the same place. Stand back about two mm and make a connection;

- With temperature differences, the siding shrinks and expands, this should be taken into account during installation. The difference in size reaches 6 mm.

In cold weather, you can also do the cladding. Only the temperature should not be less than 10 degrees.

And you need to do everything quite carefully. Plastic at minus temperature becomes quite fragile.

In many cases, siding is used under masonry.

In this embodiment, the fastening is done as follows:

- We trim the panel along the left edge so that the edge is even;

- After that, we start the panel in the corner platband in the starting bar and make fastening to the battens lath;

- We carry out the docking of the panels by the groove method. We insert the starter into the bar and carry out the fastening;

- The last panel is first tried on and cut to the desired size. After that, the corner-casing is attached and installed, which will hide the junction;

- We make the finish of the entire surface. And at the end of the work, we fasten the finish strip of the socle.

All work is done correctly. If you followed the installation technology, then the repair will not bother you soon.