Paint rollers: what are and where to apply

How to choose a paint roller? Any such tool turns boring work on decorating the premises into a creative process. Rollers are made in a wide variety of designs and sizes. When choosing a product, you must take into account the task. How to paint with a roller, the tricks of their use will tell the article.

The content of the article

Types and application of rollers

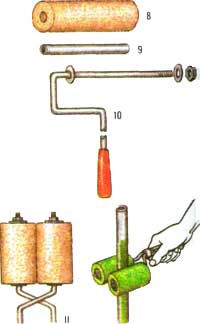

Simplest roller for painting ceilings or walls - a wooden or plastic cylinder with a full-length hole; bushings having the form of washers made of copper or other material are installed on its ends. The product is equipped with an axis with a handle.

A stop is installed at one end of the axis, a thread is cut under the nut and washer, or a cotter pin is installed. A cover or nozzle is put on and fixed on the roller. During assembly, free rotation of the cylinder around the axis should be ensured, preventing it from slipping.

With this design:

- Significantly improved performance.

- The shading of colors is changing qualitatively.

- The compositions can be applied on any basis.

- Drops or splashes do not get on other surfaces.

- No fibers or hair remain on the layer after application.

- Coating is carried out evenly, without any trace of the material of the cover on the roller.

Rollers and mini-rollers are made of various materials: natural - clamshell, velor or artificial:

- Polyamide rollers all types of paints are made, made on the basis of which contain solvents or water-dispersion compositions. Such material is able to absorb and give paint well. It is easy to clean, does not require special care, and is resistant to aggressive elements that make up paints.

Polyamide is a fairly wear-resistant material that allows you to achieve excellent results when painting surfaces with any type of paint. Convenient pile length, thin filament structure allow you to paint uneven, rough, tuberous surfaces.

- Polyacryl roller It is used when applying water-based formulations or for all types of paints and varnishes with a limited amount of solvents. Polyacrylate has similar polyamide properties, but with less wear resistance and lower coating quality.

They have a long service life, they are best suited for semi-rough surfaces, but they are also suitable for rough and smooth surfaces.

- Polyester roller dispersion paints, compositions for walls and ceilings are applied. Such a material with a uniform fiber structure, has the least resistance to wear.

- Foam roller for painting it is used for painting surfaces with water-adhesive compositions. It is absolutely not suitable for enamels, oil paints and varnishes. This is due to the fact that the solvents included in their composition corrode the foam, and pieces of material remain on the surface to be painted.

- Roller with fur nozzle used for enamels, varnishes and oil paints. The most uniform application of paint provide rollers from merlushki.

- Velours helps to get a fairly smooth surface. It is natural or with the addition of synthetics, a material with a homogeneous structure, with a short pile, ideal for coating smooth surfaces, it allows you to create a uniform, good quality layer.

- Structural rollers serve for applying plasters and structural paints to give the surface a textured fine-grained coating.

- For smoothing are clamping rubber rollers. With their help, you can drive out air from under the wallpaper, roll seams, evenly distribute glue on the surface.

- Plastic Clamping Products are used for rolling wallpaper stitches.

- Needle roller It is used to perform drywall perforation and wallpaper removal.

- Paint roller for filling the floor. Serves for rolling the front layers of the hardened composition, to remove air or deaeration.

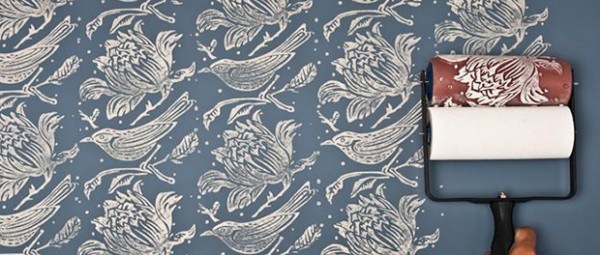

- Paint roller for decorative painting It is intended for applying plaster and thick paint to obtain a relief surface (see Rollers for decorative plastering and creating a relief surface).

- Paint roller for painting corners, in the photo VMU, is used for internal corners.

- Panel rollers convenient for applying panels so as not to cut stencils or make a special line.

- Paint Roller, fences of balconies, stairs and other objects.

How to paint bark beetle plaster

Stucco bark beetle is one of the most popular types of decorative coatings. It can be used to decorate exterior and interior surfaces. Fairly simple painting technology and affordable price, combined with a spectacular appearance.

By cons when staining the bark beetle include:

- The presence of a variety of depressions and bulges, complicating the color of the surface. To paint such a relief with an ordinary roller is quite difficult. In this case, you will need to use manual painting with a brush.

First, the surface is painted with a roller.

Tip: To stain the bark beetle, you should choose a thicker roller.

The tool is saturated with paint as much as possible, which can flow into all cavities and paint the elevations.

Tip: If there is a buildup of paint in the recesses, it must be collected with a dry roller. All appeared non-colorings should be tinted with a brush manually.

- When staining a bark beetle (see Painting bark beetle plaster - all ways) in one color, the coating does not look too pretty.

It is better to double-paint the surface, with the second layer applied in a different color. Thus, a spectacular appearance is achieved. In this case, potholes and grooves will remain with the original layer, and a different color will be applied on top.

The disadvantages of the bark beetle include the difficulty of applying a two-color layer with your own hands.

To paint the surface in two colors, you must:

- Add color when mixing directly into the plaster. In this case, the coating acquires the desired color in the preparation of the material. You can use ready-made colors, which need only be thoroughly mixed.

- When painting the coating, it is better to use a special roller for painting the bark beetle. It is a little more difficult for them to paint the surface and the paint consumption is slightly larger, but with this tool it is possible to effectively cover all the furrows on the surface.

How to clean and save the roller after work

High-quality tools are quite expensive, but they can serve for a long time, if you take care of them properly. Before saving the roller after painting, it should be properly cleaned after use.

The instruction for cleaning the roller from water-based paint offers:

- Prepared by:

- capacity;;

- cleaning solution;

- softener for all rollers used during operation.

- For each type of roller, the bucket is filled with warm water and two cups of material softener are added to it and everything is thoroughly mixed.

- After dissolving the fabric softener, the solution breaks the tension of the surface of the water and the paint begins to dissolve faster.

Tip: If necessary, the roller can be cleaned with plain water or a mild detergent that is intended for washing dishes. In addition, the paint can be rolled out on newspapers laid out on the floor, previously removing the excess by rolling the roller with pressure in the paint tray.

- The roller is lowered into the bucket with the prepared solution for 20 seconds.

- The tool is removed from the bucket and washed under a stream of warm water until the liquid becomes clear.

- After peeling off the paint from the roller, it is necessary to squeeze it out of the water as best as possible and put it on an old, preferably terry, towel. You can use paper towels in a thick layer so that all moisture can be absorbed.

To clean oil paint:

Tip: Do not take water to clean the roller when using oil-based paints: the paint will not dissolve in water alone, it must be removed with alcohol or turpentine.

- Excess paint is removed from the roller by rolling it back and forth across old newspapers.

- Pour alcohol or turpentine, which will serve as a solvent for the paint, in a clean dish.

- The paint roller is lowered into the solution and rolled back and forth, as when painting.

- The tool is rolled over old newspapers and if there is more paint on it, the process repeats.

- After cleaning, the roller is hung on a nail or any hook for drying.

- After drying, the tool is covered with aluminum foil or plastic film to protect it from dirt and dust.

Details about the care of the tool will show the video in this article.

Some tips for using paint rollers:

- If the repair is suspended for a short time, the roller can be put in a plastic bag, which will protect it from drying out.

- The tool can be stored in a tightly closed bag in the refrigerator. After this, it will take some time to defrost it before using it.

To apply paint on the surface, it is necessary to choose the right tool, and after completion of work, provide it with proper care and storage.