How is insulation for walls in different versions

Types of thermal insulation of walls can be divided into two main types. It is external and internal. The most effective is external treatment, but sometimes it just can not be done, then the internal one is done.

In both cases, you need to choose the right material to do the work, today we’ll talk about how heat and sound insulation of walls is done and which material is better to choose. Also on the video in this article and photo you can get additional necessary information that will help to do the job correctly.

The content of the article

Thermal Insulation Requirements

Thermal insulation of the walls of buildings must meet certain requirements, and they are required:

- Have low thermal conductivity;

- Meet fire safety requirements;

- Comply with environmental and chemical safety standards.

- The material used must not support combustion, emit hazardous compounds into the air, and contain hazardous chemical elements.

- For internal work, the material is selected with particular care, environmentally friendly and safe. This is important, because - in a confined space, with constant contact, even a seemingly not significant deviation from the norm can be dangerous, and for both people and pets.

Heat and sound insulation of walls should be done based on the characteristics of the material. After all, you need to know what thickness of material you need. In the photo below you can find out the thermal insulation indicator for the most used materials.

Attention: When choosing a heater, the density and heat transmission qualities are determined, taking into account the place of its application, weather and temperature features, as well as the state of the building itself.

Characterization and features of heat-insulating materials

The internal thermal insulation of the walls and the exterior is done with various materials. They have not only different prices, but also characteristics.

So:

- Materials for heat conservation are divided according to the composition of primary raw materials: organic, inorganic and mixed. The most popular and sought-after by builders heaters that have the same density.

- Materials for external surfaces are composed of mineral wool and concrete. Inorganic fibrous insulation is the most used in construction. They have gained popularity due to quality criteria: they pass steam well and are fireproof. Air when it enters does not turn into damp, but remains in its original form and, accordingly, affects the return of excellent thermal insulation.

Glass wool

This material has been proven over many years of use in various installations and repairs.

- Its heat permeability consists of 0.035 and 0.045 W / m3. These indicators helped mineral wool to recommend itself well among other heaters (see.How is insulation of walls outside with mineral wool).

- It is used mainly in construction, various industries and shipbuilding for thermal, sound and fire insulation.

| Benefits | disadvantages |

| In the markets, not bad enough material with good characteristics and not a lot of cost. It is used for warming different sizes of houses. It is highly flammable, has good electrical properties and vapor-permeable elements. | Generally not durable, but hygroscopic.

|

Stone wool

Vapor permeable insulation is widely used, as it is resistant to ignition. It is protected from settlements of microorganisms and insects causing rapid wear.

It will last for many years due to its quality characteristics. It is applied to external designs, as a heat insulator. If it is chosen for partitions.

Stone wool is an excellent sound insulator. So in addition to insulation, you will conduct sound insulation.

- According to the recommendations of specialists, such material is good for decorating basement walls. It has different density coefficients (from 0.030 to 0.040 W / mK).

- There are species with a higher density and are used for areas where operational loads are quite large. For example, for soundproofing a floor covering. But, as in the mineral material, rodent settlements are possible. They justify their holes and moves. This is perhaps one of the negative indicators.

Attention: Organic insulation materials are very popular today: polyurethane foam, polystyrene foam and penoizol. They, like glass and stone wool, have worked well.

Polystyrene foam material

The device for thermal insulation of walls has recently been encountered quite often. Although a heater with a low density index (from 0.025 W / m3 and more) it is considered one of the most used heaters for insulation at construction sites.

With the help of expanded polystyrene, the external walls of houses are insulatedbasement floors and slabs using cement-sand screed.

| Advantages | disadvantages |

|

Organic solvents are not allowed. |

Polyurethane foam material

It is widely used in building installations for wall insulation and roof repair. It has much better quality criteria for comparative factors with polystyrene foam and mineral wool.

Features and disadvantages of polyurethane foam insulation:

- Density coefficient - from 0.025 W / m3 and more. It has a low passability of the pair and this brings it closer to waterproofing materials.

- Not suitable for thermal insulation of wood. Resistant to moisture, temperature changes, regardless of the season.

- Refers to fire hazardous materials. When burning, toxic toxic substances are released.

- When the installation for insulation takes place, you need to adhere to all technological processes.Warming with polyurethane foam is a difficult job and if you do not follow at least one point, the material will not last long. Such a factor will lead to additional costs. If you can’t cope with the task yourself, then it is best to contact qualified builders.

- The main reason that affects widespread use is price. It is much higher than all other heaters.

- Polyurethane is made in the form of foam and is easy to use using special tools. They process the external surfaces and cracks in the walls.

- Due to its excellent quality indicators and density coefficient, the insulating material is indispensable for buildings requiring insulation installations.

Caution: Suitable for home minor repairs on thermal insulation. It is a foamy composition in a metal spray and is also called polyurethane foam.

Heat Insulator - Penoizol

This is one of the types of foam. In construction areas it is used only for thermal insulation.

Attention: Its liquid composition is pumped under pressure into the gaps of walls and ceilings. Thanks to this characteristic, it can be used to achieve the most negative result, in contrast to traditional heaters.

Penoisiol with its structure penetrates into all empty places, cracks. After all, even the walls have the property of aging.

Brief description of the material for insulation.

- If ignited, it may become charred, but will not support subsequent sunbathing. When burning, toxic gases harmful to health are not emitted from it, which is not good for the human body, which cannot be said about polystyrene foam. This material will not serve as a shelter for mice and rats.

- Penoizol is well vapor permeable due to the capillary structure. This advantage took the heat insulator to the highest steps of popularity. It is used for warm decoration of wooden rooms and large buildings. In a word - there are no restrictions on its installation.

- Does not allow mold and other defects to appear through the reproduction of microorganisms.

- The internal system of the capillary structure helps to cope with moisture. It effectively dries the internal moisture. Do not use penoizol for structures where you get a connection with the ground. He is afraid of concrete coatings and thereby his thermal insulation qualities are worsened, which will lead to defects.

When choosing a heat-insulating material, it is worth considering the scope of application. In the construction markets, there are many varieties of insulation. They have different qualities, features and disadvantages. Pricing policy depends on the nature of installation. With specialists, the right choice can be made easily.

Thermal insulation

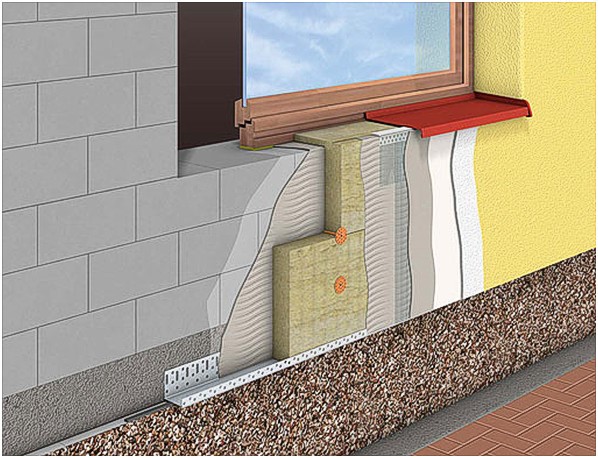

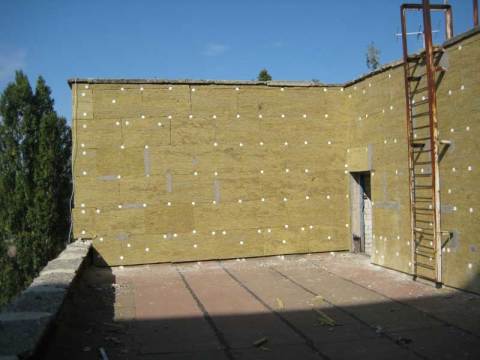

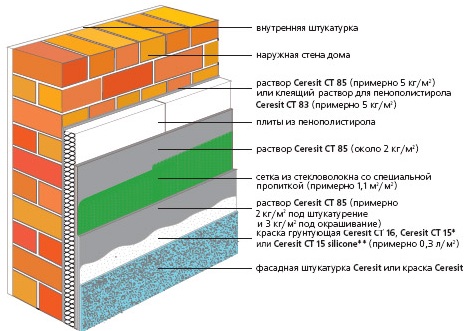

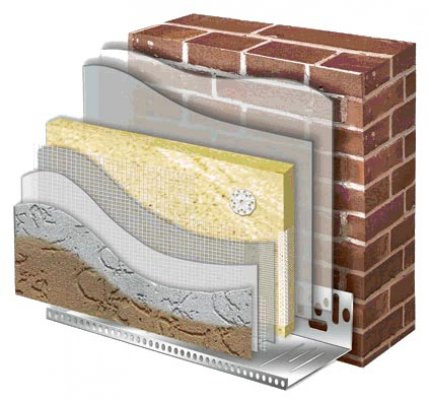

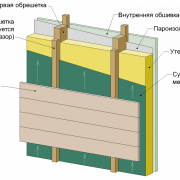

Wall insulation is carried out according to certain rules, they are tested by time. Basically, for fixing the insulation, a crate is made, but already the material itself is attached in different ways. Now we will consider how the installation of thermal insulation of walls is done.

The work is done in the following order:

| To do this, we pull the line along the diagonals of the plane and measure it. Here it is necessary to pay attention that the gap is made more than the thickness of the insulation by a couple cm. It must not be deformed during installation, otherwise it will lose its properties. | |

It can be performed in two versions. It is metal and wood

| |

| The thermal insulation of the walls from the inside should not be deformed, otherwise it will lose its properties. So be sure to consider this when attaching and choosing the step of the crate. | |

| Mounting can be done in two versions. The installation base is of great importance here. If the wall is thin, then we use glue for fastening. If it is a brick or a bud, then the use of plastic fungi will be the best option. After that, a heat-insulating film for the walls is applied. Also, a tape for thermal insulation of walls can also be used. | |

| Here you select the desired finishing material according to the design. If this is a tile, then just sew it up with drywall, it creates an ideal base for fixing almost any material. |

Draw conclusions

Based on the foregoing, the following conclusions can be drawn:

- Work such as this is carried out, as an exception, in cases where there is no other option. The most acceptable is a comprehensive insulation, which includes both the floor and the ceiling, as well as the attic and roof. In this case, the result will be tangible.

- It is not disputable that before starting work, it is necessary to carry out diagnostics in order to identify possible defects, as well as in order to determine the choice of materials, taking into account weather conditions, identifying the dew point.

- The selected insulation must comply with fire safety standards, be environmentally friendly.

- All types of insulation material that can absorb moisture are used with insulating films.

- Using wood as a building material in the work, processing with a composition that prevents fire and rotting is mandatory.

- Insulating films, before use, are carefully studied so as not to confuse the parties.

Wall constructions of increased thermal insulation are also made with their own hands, but this is better done at the construction stage. So you can make your choice of material, the instruction will help you avoid mistakes.