Warm plaster: composition and features of use

Plaster warm in the sales market appeared not so long ago. But for some works, it will simply not be replaceable.

Today we will consider warm plasters, you will learn their application and instructions will be given on the application rules. Also in the video in this article you can see the range of products offered and can make the right choice.

The content of the article

Types of material

Types of warm plaster are divided according to the use of components.

Having looked, we can see the following:

- The basis of one type of warm plaster is expanded vermiculite., which is a mineral additive obtained as a result of special heat treatment of rocks of volcanic origin. Vermiculite fillers have antiseptic properties and can be used both outdoors and indoors.

- The basis of the next type of heat-insulating plaster is paper, sawdust, clay and cement. This composition does not allow its use outside buildings, but is great for indoor use.

Attention: It is possible to cover all types of planes with this type of plaster, including wood. Much attention should be paid to drying the plane. For 2 weeks, when it dries, it is necessary to provide active ventilation of the room, otherwise, mold or, even worse, fungus may appear on its surface.

- The next type of warm plaster is made on the basis of expanded polystyrene foam granules. In addition to it, the composition of the plaster includes cement, lime and a number of other additives and fillers.

A mixture based on polystyrene granules is very popular, therefore, in this article its main technical characteristics will be described in more detail.

This type of plaster is used:

- For thermal insulation and facade decoration.

- For plastering window and door slopes.

- Additional wall insulation when applying masonry.

- As an additional element of insulation and sound insulation.

- For interior decoration, with additional sound and heat-insulating effect.

- For thermal insulation of engineering structures designed for supplying cold water and sewage systems.

- For work on the insulation of floors and ceilings of buildings and structures.

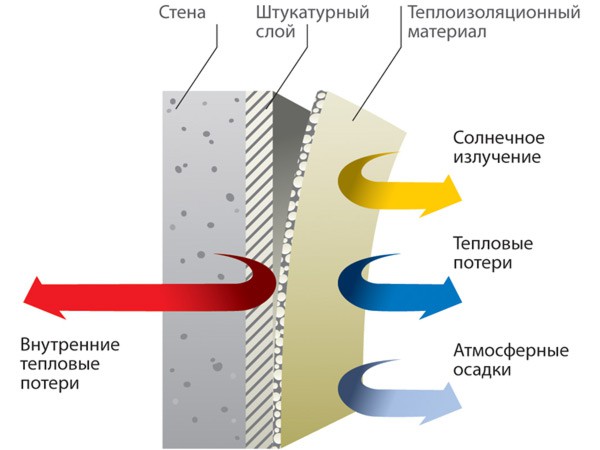

To understand how effective warm plaster is, it is necessary to make a comparison with other warming compounds and materials.

A mixture of heat-insulating plaster

Such a good coefficient of thermal conductivity of the plaster was achieved due to its rare composition. Instead of sand, warm plasters use materials that have low thermal conductivity.

The composition of warm plaster consists of:

- Expanded polystyrene granule.

- Expanded vermiculitis.

- Sawdust.

- Perlite (perlite sand).

- Expanded clay crumbs.

- Crumbs or pumice powder.

Warm plaster, based on polystyrene granules, is very popular. This is due to the fact that it is cheaper, but has not bad operational parameters, while it is possible to use both inside and outside buildings.

In addition to polystyrene granules, it includes:

- Plasticizers.

- Lime.

- Additives.

- Cement.

Warm plaster based on polystyrene granules has the following technical characteristics:

- Specific Gravity: 200-300kg per cubic meter.

- The heat transfer coefficient is 0.065W / mS.

- The coefficient of water absorption is 70%.

- Fire Safety Group - G1.

Attention: On sale you can also find warm plasters based on sawdust, paper, clay and cement. This type of plaster is called internal, since its use outside the premises is not possible due to the high hygroscopicity.

In addition, this plaster requires a long time to dry, as well as good ventilation for this period, otherwise it may cause fungus. In addition to these types, plastering based on vermiculite, processed by a special technology, is on sale.

Advantages and disadvantages

Widespread heat and sound insulation plaster, which is based on sawdust or polystyrene granules, has several advantages:

- Simplicity and speed of product application on building surfaces.

- Full compatibility with all types of surfaces, including wood.

- The surface does not form bridges of cold.

- The surface of the warm plaster is not damaged by rodents.

- Environmentally friendly product. The thermal plaster video will tell you about this.

- Its basis is constituted by components of natural origin.

- It retains its basic characteristics under all operating conditions.

- It is not a distributor of fungal diseases and mold.

- It does not contain harmful substances.

- Its price is higher than the cement composition and it is quite difficult to make it with your own hands, but its quality is not in doubt.

Despite the large list of advantages, such plasters have their drawbacks:

- This type of plaster involves applying on top of the plaster layer, layer finishing putty or plaster.

- The need to cover a much larger layer than when using traditional insulation systems.

- Fairly high cost, especially those types of plasters that do not need a top coat.

- The inability to apply a layer thicker than 2.5 cm in one go.

- It has shown its effectiveness in plastering window and door slopes, in sealing small flaws, such as sinks, cracks or delaminations of ordinary plaster, as well as as insulation of the internal surfaces of residential premises, where the thickness of the insulation layer plays a large role.

This is a modern building material that can become an alternative to traditional types of coatings. Based on its main characteristics, warm plaster surpasses many widely known and popular specimens in many respects.

Technique for applying warm plaster

Since the application instruction is almost standard, but you can apply this type of plaster yourself, without involving specialists.

The technology of plastering consists of the following steps:

- All necessary materials and tools are prepared, such as spatulas of various sizes, trowels, as a rule, a construction mixer and level, dishes for mixing plaster, metal beacons.

- The surface is preparing for plastering: dirt and dust are removed; if necessary, it is leveled.

- Primed walls, if indicated in the instructions for use of this type of plaster.

- The plaster mix is mixed. To do this, the entire contents of the bag are poured into the container, water is added and mixed with a construction mixer. After this, the mixture should be infused for 5 minutes.

- Metal beacons are installed on the surface.. They must be installed strictly vertically and in the same plane.

- Prepared warm plaster is applied to the wall with a trowel, and it is leveled by the rule, which should rest against the lighthouses. Excess solution is removed and reused. The plaster layer must have a thickness of not more than 2.5 cm.If you want to apply more plaster, then this is done in no less than 4 hours.

Attention: When applying a layer thicker than 2.5 cm, freshly applied plaster may slide or completely fall off from the surface.

- If after the beacons are exposed, it turned out that the layer of plaster can be in places more than 2.5 cm, then first apply the layer without alignment. Such a layer can be thinner than 2.5 cm and this is absolutely normal.

- Heat-insulating plaster based on expanded polystyrene granules is not intended for decorative processing of walls, since it has low mechanical strength. Therefore, on top of this type of plaster, you definitely need to apply a protective layer that has good indicators of mechanical strength. This property of this plaster must be taken into account when using this type of plaster.

- Given the fact that it is worth a lot, the calculations should be done very accurately, especially in cold regions, where preference should be given to more serious insulation technologies, when a layer of warm plaster of 50 mm can hardly be dispensed with.

Attention: Another thing is the combined approach, when serious thermal insulation measures are carried out outside the building, then inside the building it is possible to use warm plaster.

DIY warm plastering is generally not applied. But look at the photo and you will see that it is completely indispensable for warming windows and doors. Although the decision to make you.