Stucco on foam concrete blocks: do it yourself

Plaster foam concrete is not so simple, because the porous structure of the material does not hold the solution and this creates certain problems. First you need to decide what to plaster foam concrete. After all, the material is of great importance and after that you will learn how to plaster houses from foam concrete. Also, the video in this article and the photo will show you the individual moments of the work.

The content of the article

Foam blocks and plaster

The foam blocks made by casting are very smooth, so they must first be skinned, and mixtures with a high adhesion index should also be used for work.

Unique properties of foam concrete:

- Durable material

- It is highly resistant to temperature differences.

- It has excellent heat saving and sound absorption

- It has a minimum shrink coefficient

- Easy building material, therefore convenient in operation and during transportation

- Good water repellent

- Easy to process and clad

Attention: Remember that if you do not follow the technology of applying the stucco mixture, you risk nullifying all the positive properties of this unique building material.

Features of work

Foam concrete blocks - a building material popular in our time, as it is lightweight, has good heat-insulating qualities, is easy to install and affordable. He has already made good competition to other building materials. In terms of its performance, foam concrete is similar to wood, it has lower thermal conductivity than brick.

- Foam concrete consists of sand, foam and water. Foam is the main component and gives the material unique properties. Not only houses are built from foam concrete, but also baths (see Foam baths: interior decoration - do it yourself) Foam blocks are suitable both for the construction of partitions inside the building, and for the construction of individual load-bearing structures. The structure of the material is porous and this brings its own characteristics to the rules of work.

- Plastering and painting are the most popular ways. cladding of the house from foam blocks. However, when plastering walls from foam concrete blocks, some difficulties arise.

Attention: The main problem of high-quality plastering of walls made of foam concrete blocks is poor adhesion (adhesion) of the plaster to the wall surface. The material does not just need to be applied, but it is also necessary that it lasts a long time, so do not neglect anything in this matter.

- It is difficult to high-quality plaster the foam block using conventional sand-cement and lime mixtures (seeWe prepare ourselves a mortar for lime plaster) They are usually used for rough plastering, when you need savings in construction work. In this case, there is a risk that the plaster will simply fall off.

It is especially difficult when there is a need to put a layer of plaster over 3 cm on the foam blocks or you need to plaster uneven walls.

But here, as in any other business, there are secrets, using them you can greatly improve the adhesive properties of the walls of foam concrete blocks.

If you decide to do the work on plastering foam blocks with your own hands, we recommend using these tips:

- It is rational to use special fluids when plastering foam blocks, which improve the adhesion of the foam block: concrete contacts or primer paint.

- Must be used when working reinforced plaster mesh. It prevents cracking of the plaster layer when the building subsides.

- Before plastering, you can sand the surface of the blocks with sandpaper. (cast blocks)

Attention: All tips come from the fact that the foam blocks on top are saturated with a substance that gives them water-repellent characteristics. As a result, the walls will not get wet during rains and snow outside and will not be wet and damp inside. Therefore, remember that when sanding this layer, you are depriving the material of moisture-resistant properties.

Plastering mesh

Stucco for foam concrete will hold high quality with the use of building mesh. Its price is not high, but the return will be tangible.

- It is better to choose a polymer grid, for example, plastic (for plaster mesh for indoor plastering). Plastic plaster grid: material features), since it is more economical, lighter, and resistant to corrosion. As a result, the plaster will be more durable and better.

- Metal meshes rust and cause yellow stains on the plaster. The main thing during plastering is to be able to fix the grid as close to the wall as possible, the thickness of the plaster layer that will be obtained when applying the mixture depends on it.

Why wall plaster of foam block is needed:

- Improving the look.

- Protecting the wall from temperature extremes

- Thermal Insulation Improvements

- In order for the steam to pass freely outside

- Protection against precipitation, moisture and moisture

- To prevent carbon dioxide and dust from saturating the walls and ultimately to prevent them from shrinking

Mixes for plastering on foam concrete blocks

Foam concrete than plaster now consider in more detail. The main condition that the plaster mortar for the foam concrete block must meet is good adhesive properties.

Therefore, stucco mixtures for foam blocks are lighter in weight, this helps them to stay easier, overcoming poor block adhesion. There are many mixtures of well-known manufacturers for plastering foam blocks.

The most optimal in cost and quality are such mixtures:

- Sh-36 "Decor" —Mix consists of cement and reinforcing fibers. This plaster mix is easy to lay and holds well.

- Aegis 42 and 35 (“Win” Series) - high-quality plaster mix

- Glims velur - Strong plaster, does not crack when the walls shrink.

- "Ceresit CT24" - An economical, but at the same time very high-quality mixture. Very popular for ease of use and good performance.

It will also be necessary to determine the composition, the following information will be useful here:

- Gypsum putty mixes are the most economical, suitable for dry rooms where there is no high humidity, since under these conditions they exfoliate. Therefore, these mixtures are not used to repair bathrooms and basements.

- Finishing polymer blends when dried give a smooth surface, sometimes not even requiring wallpaper stickers. However, their price is more than 2 times more expensive than conventional finishing mixtures.

- Foam blocks are made of aerated concrete in several ways: injection and sawing. For plastering, it is preferable to use sawing foam blocks, since the stucco mixture sticks to them more easily.

Attention: When preparing the plaster composition, you should get a completely homogeneous mass. So for a batch, use a mixer or drill with a nozzle. Then the composition will be prepared quickly and efficiently.

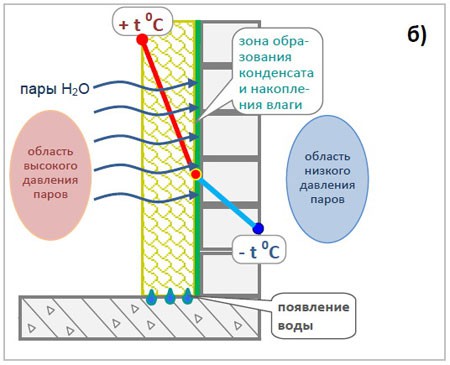

Dew point and troubles associated with it

The properties due to which foam blocks have gained their popularity are minimal thermal conductivity, and as a result, good heat-insulating characteristics. A minimal amount of cold can still seep through the wall material and glue.

External plaster prevents freezing of the wall. But an excessively thick layer of plaster inside will not allow the blocks to warm up to the desired temperature in the cold, this will cause the dew point to occur.

Attention: It is formed in the event that cold air which has got through a wall meets warm at the border of foam concrete blocks and a layer of plaster inside. The dew point causes constant humidity of the walls and mold under the wallpaper, as a result we have a sloppy type of repair and a disturbed microclimate in the room.

If you are going to putty yourself, so that there are no problems with the dew point, follow the basic rule: the layer of plaster on the inside should correspond to the layer of plaster on the outside, like 1: 2, that is, be twice as thin. This condition will allow you to shift the dew point to the outer part of the wall and get rid of excess moisture in the living room.

Tools for plastering foam concrete blocks

The same tools are used for plastering on foam blocks (see Wall plastering tool: what you need to work), as with similar work with other materials.

- Drill equipped with a mixing nozzle. Needed to beat the mixture to the desired consistency

- Spatulas of various sizes - for applying plaster mix

- Level

- The rule

- Roller or large brushes for coating foam blocks with a primer.

Professional Tips

Plastering on foam concrete blocks is not such a difficult task, but there are no trifles.

Specialists give their recommendations in the following form:

- Plastering inside the house should be done no earlier than a month after raising the walls of the house. It is known that if the walls of the blocks give decent shrinkage, the plaster may crack and collapse.

- The best temperature for these works is from 5 to 30 degrees. It is impossible to carry out plastering work at zero degrees and below.

- Prepare the surface before applying the mixture: clean it from dirt and oil stains.

- When plastering in several layers, the next layer should be applied only after the previous one has completely dried.

- It is necessary to apply a primer both on the blocks themselves and on the surface of the plaster from the outside.

- The thickness of the internal plaster on the foam block should be no more than 10-15 mm. The consumption of the mixture in dry form per layer in 1 cm of thickness will be approximately 1.1 kg per square meter. surface meter. When applied in one coat, the amount of primer will need 150 g / m2.

Step-by-step instructions for plastering foam concrete walls

All work is done in the following sequence:

- To free the wall from dirt and dust, we also look at the seam, it is better to deepen it by one cm. This will provide better adhesion;

- Degrease or cut down oil stains, because the solution will not stick to them. It is best to walk along the plane with a coarse grain grinder;

- Apply a primer (seeWhy do we need a primer: technological nuances of finishing work) using a roller or brush. It is preferable to use primers with the properties of deep penetration. If the plane is large, then it is better to purchase a spray gun, then the coating will be done quickly and evenly;

- Install plaster mesh on the wall

- When a thicker plaster layer is needed, it is recommended to use beacons to make it more convenient to level the surface. To determine the level of the layer, you just need to pull the line along the diagonals and you will immediately see the desired layer;

- Spray the wall or moisten with water. This will improve the adhesion of the mixture and surface.

- Apply the mixture on the wall with a trowel and level it with a rule. At this stage, you do not need perfect evenness.Here you just have to maintain a common plane;

- Remove excess plaster from the wall, smooth out any irregularities when the layer dries a little;

- After drying the plaster with a spatula, remove the lumps of the solution, cover the surface with a primer;

- Apply and smooth the final coat with a spatula. Here we already use a wide spatula, which will make a smooth surface;

- Now let the composition dry. All this could well be done with a simple cement composition. But such a mixture is not suitable for the finish, it has a large grain size and this will not make the plane perfectly smooth.

At finishing putty plaster, waterproof and polymer mixtures are used.

- The composition is not very dry, it should be ductile. Apply it with a wide spatula;

- We are waiting for drying and grouting using a building mesh. After this, shells form;

- We make their putty with a rubber spatula and a liquid solution;

- Give drying and polishing the plane.

Now you know how to plaster a house from foam concrete. The instruction will not let you make mistakes. The most important thing is not to rush and do everything consciously.