Foam houses: outdoor decoration - a variety of options

The durability of the walls of foam blocks directly depends on the quality of the outer lining. It should be said that the structure of the foam concrete is very porous and moisture easily penetrates its thickness.

In this regard, it is necessary to pay special attention to waterproofing during the finishing process. If this is not done immediately, then in a few years you will have to replace the lining.

The main requirement that is imposed on the exterior walls of foam concrete is the unhindered removal of water vapor outside the house.

The content of the article

Facade cladding

The following methods are recommended for facing facades of foam blocks:

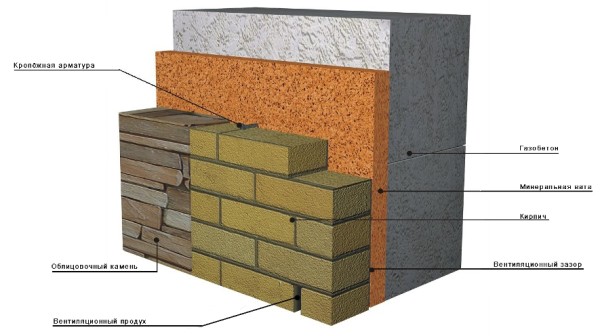

- hinged cladding, which involves the presence of an air gap between the wall and the finish, the so-called ventilated facades;

- Facing walls of foam concrete with a facade stone or brick, provided that there is an air gap between the wall and the cladding;

- it is possible to plaster the foam concrete facade with a specially developed stucco mixture, which allows the walls to "breathe" freely;

- it is also possible to paint the facade with silicone paints, after having previously wiped the seams between the blocks. Such paints are vapor permeable, that is, moisture vapor freely leaves the interior;

Exterior foam block facing with brick

If you have the experience of a bricklayer, then you will be able to revetment the facade of your house yourself, having one assistant with you.

To do this, you will need such a tool:

- drill - hammer drill;

- hammer;

- level length 80 cm;

- scissors for metal;

- roulette;

- plaster trowel;

- nozzle "mixer" for mixing the solution;

Starting laying, you should adhere to such rules:

- to prevent sand settling, be sure to mix the solution before laying;

- the mortar is applied evenly along the entire length of the brick, with a thickness of 10 to 15 mm;

- if the spray of solution gets on the front side of the brick, then they must be removed immediately, then it will be much more difficult to do;

- calculate the required amount of brick in advance and add another 10% to this amount. In the process of transportation and laying, some part of the brick is sure to suffer.

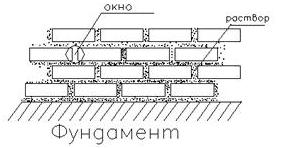

If the brick is not enough and you have to buy from another party, then you are unlikely to pick up exactly that shade; - facing brick is laid on the protruding part of the foundation, which must be provided in the process of laying it. The width of the protrusion should be equal to the width of the brick plus the thickness of the sealant and plus a ventilation gap of 3 cm;

- during masonry in the bottom row, it is necessary to leave every fifth vertical joint between bricks without a solution;

- the same ventilation windows must be done in the very top row of the masonry. These are the so-called purses.

They are made in order to ensure the free passage of air, ventilating the facade, and thus mold and fungus on the load-bearing wall are not allowed.

- The cladding wall must be securely fastened to the load-bearing wall, withstanding wind loads and temperature extremes.

You can fasten the lining to the foam blocks in the following ways:

- spiral nails;

- perforated galvanized strip;

- basalt-plastic bonds;

- The perforated strip is used to fasten the cladding to the foam blocks during the simultaneous erection of the load-bearing wall and facing.

- The perforated strip is first nailed to the horizontal side of the foam block, and then inserted into a brick seam.

- Such galvanized jumpers between the main wall and facing should be at least 5 pieces per 1 m².

- With spiral nails, you can fix the facing brick to the foam concrete wall at any stage of installation of the main wall. One end of the spiral nail is hammered into the foam concrete block, and the other end is laid in the seam of the facing wall.

Recently, basalt-plastic ties have been widely used for fixing cladding to a bearing wall.

- This connection is a round rod with a diameter of 4 mm with sand spraying at the ends. This spraying promotes good adhesion to the solution.

- One end of the rod is inserted into the vertical seam on the load-bearing wall, and the other is laid in the horizontal seam of the cladding.

- For reliable fastening of a facing wall it is enough to establish 4 communications on 1 m² of a laying.

Home decoration from the foam block outside with natural or artificial stone, although it does not add noise and heat-insulating properties, it will reliably and permanently protect the load-bearing wall from the weather.

- The entire wall or individual elements can be revetted, combining stone decoration with decoration with other materials.

- Exterior wall decoration of foam concrete blocks with both natural and artificial stone is done in the same way as with facing bricks.

Exterior wall decoration of foam block siding

Siding - This is the most economical and fastest way to clad a facade from a foam block.

The advantages of this method are as follows:

- durability (up to 50 years or more);

- siding is not exposed to ultraviolet rays;

- not subject to decay and mold;

- fireproof;

Vinyl siding fully possesses such qualities:

- This is an inexpensive and quality material.

- With it, in a week you can completely sew up the entire facade.

- Siding made of polyvinyl chloride (PVC) looks very nice on the facade of the house.

- It has a wide range of colors so that you can choose the colors of the facade for every taste.

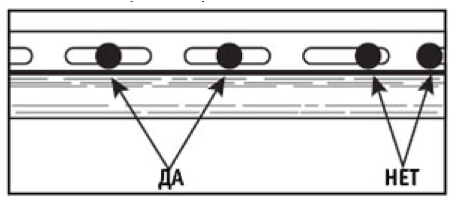

Please note: when installing PVC siding panels, it should be borne in mind that vinyl has a significant coefficient of expansion or contraction when the temperature changes, so you should not nail or nail the screw so that the panel has free movement.

To install siding, you need the following tools:

- hacksaw for metal;

- building cord;

- level;

- roulette;

- hammer;

- construction square;

Do-it-yourself mounting siding, follow these rules:

- A lath of beams of timber with a pitch of 0.5 m is vertically fastened throughout the facade, the thickness of the beam is 8 cm.

- 5 cm thick polystyrene insulation is placed on the solution between the bars and fixed with a dowel with a wide washer.

- Installation of horizontal siding should begin with the installation of the start profile. Be sure to check its installation by level.

- The lower part of the first panel is placed in the lock of the starting profile, and the upper side is fixed with nails or screws as described above.

- A gap of 3 cm remains between the panel and the insulation. This gap will ensure air circulation and the removal of moist fumes from the interior of the house.

- When installing the next panel, it should be coupled with the locking protrusion on the previous panel and secure the upper part with nails or self-tapping screws without interference.

- Siding panels have elongated mounting holes. This is done so that the panel has the ability to expand or contract with temperature.

- Fasten the panel with nails or screws in the center of the hole.

- Do not press the heads of the nails or screws tightly against the panel. This is done so that the panel has free movement.

Otherwise, it may become deformed. - Installation of siding panels is from bottom to top.

This type of facade decoration from foam blocks differs from other types in such qualities:

- durability;

- profitability;

- ease of maintenance.

How to finish the house from the foam block with plaster

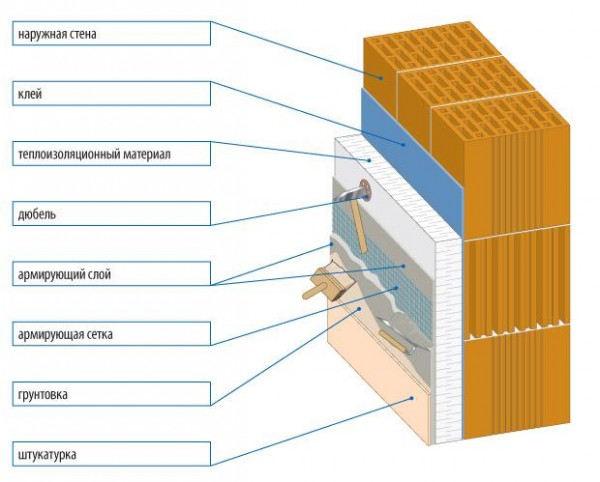

Exterior finish with stucco - this is the protection of the load-bearing wall from the influence of precipitation. If this is not done, then over time the plaster will become cracked, begin to swell and lag behind the load-bearing wall.

Plaster for finishing foam concrete blocks should have the following qualities:

- high water repellent properties;

- vapor permeability;

- good adhesion to the base;

- high compressive strength;

- high frost resistance;

Plastering the facade of the foam blocks should be carried out in the following order:

- We process the surface of the wall with a primer. This is done for long-term protection of the main wall from moisture.

It is recommended to use a primer made on the basis of acrylatesiloxane; - Before applying the primer, repair the joint defects and repair all cracks.

- The second stage is the reinforcement of the plaster layer. To do this, apply a mesh made of alkali-resistant fiberglass.

A regular grid will dissolve in a few years under a layer of plaster. All plaster will crack and begin to crumble.

- The third stage - we apply a special facade stucco mixture with a thickness of up to 9 mm.

Facade plaster should have the following characteristics:

- specific gravity - 0.8 kg / dm²;

- grain fraction from 2 to 4 mm;

- group of plasters - P1;

- moisture absorption of not more than 0.5 kg / m²;

- fire safety - non-combustible material;

- the plaster mix should be plastic, easy to apply and easy to handle;

- After hardening, this plaster will acquire water-repellent properties and at the same time will release water vapor to the outside.

- Fix the plaster with a vapor-permeable, flexible paint.

Choose the paint with the highest vapor permeability.

The best characteristics for these purposes are silicone paints:

- they have good water repellent properties;

- they are resistant to precipitation;

- prevent the appearance of mold, fungus and microorganisms.

- For greater protection of the cladding, a layer of water repellent can be applied over the decor. This will give additional protection to the cladding during periods of prolonged rain.

There is another cheapest way to decorate a facade from foam concrete blocks - this is painting the walls with facade putty:

- Such putty is produced on a water-based basis.

- Before use, it is diluted with water in a ratio of 20 kg of putty 7.5 liters of water.

- Mix thoroughly until a creamy mass is obtained.

- To obtain the desired color, the corresponding water-based dye is also added to the finished putty.

- Putty is applied with a wide brush and roller.

- It hardens one hour after application to the wall.