Stamp for plaster: how to use it correctly

Stamps for plaster made of polyurethane are used to create the necessary relief on the surface. Their inner side imitates masonry made of bricks, natural stone, patterns from plants, wood or aging walls. How to make and use stamps with your own hands, the article will tell.

The content of the article

What are the requirements for stamps

Any polyurethane stamp designed for wall plastering must meet the requirements for building tools and materials.

These include:

- High resistance to alkaline solutions.

- Increased wear resistance from abrasive materials.

- Plasticity, which eliminates the appearance of breaks in products.

- Reusable use.

- Large selection of blanks.

Common characteristics when working with polyurethane dies are:

- Processing decorative plaster can be performed with dies having various shapes and sizes. This allows you to get a large number of similar repeating figures placed close to each other. Most often, there are such figures as:

- brickwork;

- bubbles

- decorative rock.

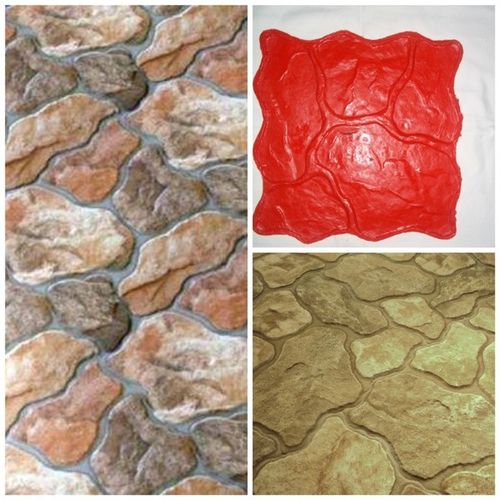

Some options for stamping plastered surfaces are presented in the photo.

- Working with such a tool is quite simple., especially when placing the picture not on the entire wall, but only in a few places.

- Before applying the coating, thorough preparation of the working surface is required. This affects the quality and clarity of the applied decorative parts. For this:

- all garbage, dust, spots of fat are removed from the treated surface;

- all visible cracks, dents and chips are closed;

- a dense primer is applied (see Why do we need a primer: technological nuances of finishing work).

Tip: It should be borne in mind that after drying, the surface should not remain slippery film.

- A stamp is placed on a fresh, compacted and leveled solution., while you need to hit him hard with a special hammer or hand, so that the tool goes deeper inward by 5 millimeters.

- The device is removed, and the specified pattern remains on the wall.

What equipment is necessary for the production of decorative plaster

Tip: When purchasing a product or making it yourself, you need to pay attention to its rigidity: the higher it is, the more clear the drawing will appear on the working surface.

In the manufacture of any composition, the basis of which is cement, you will need:

- Electric concrete mixer. Its cost depends on the volume of production.

- Vibration table. With its help, the concrete is evenly leveled, which prevents the formation of various voids inside the product.

- When planning the production of large and heavy products, you should purchase a forklift.

- Forms for decorative blanks from concrete, for pouring the mixture. The materials for their manufacture are taken:

- metal;

- wood;

- fiberglass;

- polyethylene.

The price of the finished form is quite high, but it is quite possible to do it yourself. To do this, you just need boards, chipboard or sheet metal.

- Stamps for imprinting on the surface.

How to make a stamp for concrete

Stamps for the manufacture of decorative tiles can be:

- Plastic, with great rigidity. Used in the manufacture of paving slabs.

- Softer polyurethane or silicone. Flexible dies are used to create more complex forms of concrete.

With the independent manufacture of a stamp for decorative printed concrete, its cost will be minimal. A complete instruction for its manufacture is available on the video in this article.

The easiest way is to make a metal printing screen using a welding unit. More complex forms can be molded from a polymer. But this is a rather complicated process, it does not always give the necessary result of the same quality as the finished soft stamps.

How to prepare the base for applying decorative plaster

Tip: Gypsum plaster can be applied only after the base of the wall dries and shrinks in the house. It is necessary that the base is dense, evenly absorbs water, has a rough surface on which there is no dust, oil stains, paint residues, varnish, mold and any protruding defects.

To prepare the surface you need:

- Close up with compositions with good adhesion to the base of the wall, cracks and potholes.

- Knock down and grind sprues and ledges.

- Inhomogeneous materials, which absorb water in their own way, are primed qualitatively to smooth the surface from moisture absorption, and leaking places - for the strength of the coating.

Tip: When using on walls of mixed compositions having different absorbency and on very uneven walls, a polymer or metal mesh should be applied to improve adhesion to the base of the gypsum plaster.

- Two hours before the plastering, the surface is primed. Wherein:

- walls built of cellular or lightweight, on porous aggregates, concrete, silicate brick, are primed with special compositions that make it possible to level and reduce the absorption of moisture from gypsum plaster;

- smooth bases that do not absorb moisture, get off with concrete contact primer;

- all other bases are covered with deep penetration primer.

- A little gypsum mortar is mixed.

- With small cloves with a spatula-comb, grooves are applied to the wall in the horizontal direction, and remain for drying, they will become an obstacle to the sliding of a large thickness of the layers when applying a gypsum mortar.

How to prepare and apply the solution

The process of preparing gypsum plaster or putty is as follows:

- The dry mixture is gradually poured with a small amount into clean water.

- Stirred until a creamy homogeneous mass without lumps.

The ratio of components in the solution is indicated on the manufacturer's packaging.

After preparing the composition and drying the primer:

- A layer of plaster is applied with a metal spatula to the wall. Its thickness depends on the depth of the relief available on the polyurethane stamp, and is usually 1 to 4 centimeters for concrete and plaster.

Tip: The composition should be convenient for performing consistency work, not stick to the tool used. With a large amount of water in the batch, sticking of the solution with a stamp may occur.

- The solution should dry.

Some tips when doing work:

- The mixture is applied to a small section of the wall, which is associated with the rapid hardening of the gypsum composition, and it should be stamped with a polyurethane stamp until it finally hardens.

- The mixture is considered prepared for stamping when it will not stick or reach for your fingers when it is touched.

How to emboss gypsum plaster

The stamping time depends on the ambient temperature and its humidity, the plane is embossed after the solution dries, when it stops reaching for the finger.

Then:

- The polyurethane stamp before stamping is wetted with a liquid with a small amount of detergent diluted in it. This prevents the tool from sticking to the wall surface.

- The product is gently pressed into the gypsum mixture applied to the wall (see Dry plaster gypsum mixture: features of use).

- The stamp stays on the surface for a while.

- Slowly removed.

- Using a spray gun, you can refresh before pressing the mold and the applied gypsum mixture.

- If, when the stamp is removed from the mixture, “icicles” are drawn that follow it, instead of a beautiful stone relief, this indicates that the surface does not dry sufficiently to perform such work. In this case:

- these defects need to be smoothed out with a spatula;

- wait a while;

- Re-emboss the surface with a polyurethane die.

Tip: When sticking the mixture with a polyurethane tool, even after wetting it with soapy water, the latter should be replaced with building talc.

After embossing the prepared area, the operation is repeated in the same sequence in another place until all the necessary surface is processed.

- After stamping the surface, when it dries well, you can start editing with any tool, usually a screwdriver or other durable metal, wooden or plastic tool. They remove excess solution from the depressions and grooves that are between the stones.

- The surface can be painted.

A well-chosen form of stamp for embossing walls will make any building beautiful and original.