Gypsum plaster

Rothband is the best gypsum mixture for leveling walls and ceilings,Finishing work in residential, office, public buildings. The manufacturer of the dry mix is Knauf. Composition - gypsum, mineral fillers, binding ingredients. At Cnauf plants, gypsum powder is produced by fine grinding with fraction sizes up to 1.2 mm. The finely divided substance is mixed with polymer additives, resulting in a plastic gypsum plaster Rotband. The manufacturer’s certificate confirms compliance with quality standards, fire, environmental and sanitary safety.

The content of the article

Material characteristics

- Gypsum plaster Knauf Rothband adheres well to smooth and porous surfaces.

- The complete drying time of the treated surfaces is 1 week.

- In the solid state, the material has a density of 950 kg / m³ and strength above 2.5 MPa.

- The shelf life of the mixture in paper packaging, subject to the rules, is up to 6 months.

- Plaster gypsum plaster holds firmly on ceilings with a layer of up to 15 millimeters, on vertical surfaces with a layer of up to 50 millimeters.

- Use ready-made plaster is required within 25 minutes after preparation.

- Full setting of the coating takes place in a week, plastering work is carried out at a temperature of 5-25 ° C.

Where is used

Universal gypsum plaster Knauf Rotband is designed for finishing concrete, brick, polystyrene foam substrates, surfaces from TsSP. A scope - processing of internal walls and ceilings of rooms with a normal and slightly increased level of humidity (kitchen, but not a bathroom). With a solution of the mixture, the strobes and joints of the drywall sheets are closed, the slopes of the insulated window blocks are formed, the walls and ceilings are leveled.

The material is easy to use and convenient for home repairs with your own hands. The novice master easily copes with the preparation of the solution, but it is important to correctly calculate the amount of water and dry plaster.

How much mixture to buy for work

If gypsum plaster Rotband is used for finishing work, the flow rate of the dry mixture is calculated depending on the thickness of the layer and the surface area. For one square meter of plaster of centimeter thickness, 8.5 kg of mixture will be needed. The amount of water for the solution is conveniently determined by the packing volume of the package in which Knauf Rotband gypsum plaster is sold. 30 kg bag when used is completely diluted in the amount of 18-20 liters. This mixture is enough for approximately 4 m². Measure the surface area, divide the result by 4, and get the right number of bags.

Advantages and disadvantages

Dry gypsum mixture plaster Rotband has many advantages:

- health safety;

- simplicity in work;

- drying speed;

- resistance to delamination;

- air permeability;

- universality of decoration;

- moisture retention and release;

- economical consumption;

- heat and sound insulation properties.

Knauf Rotband (universal gypsum plaster) is a material convenient for interior decoration. With its help, experienced plasterers create a variety of decorative wall textures and decoration elements.

Disadvantages:

- it is impossible to plaster external walls: with excess moisture, the plaster falls off;

- not suitable for sealing gaps between walls and door frames: due to expansion after drying, deformation and distortions of the door blocks are possible.

Rothband gypsum plaster (30 kg, 5 kg) in bags is in active demand by buyers of construction stores. This is due to the popularity of the famous brand and the proven decent quality of its products.

Rothband gypsum plaster: instruction for independent use

Photos and videos in this article will help the novice plasterer visually familiarize themselves with the technology for preparing and using the mixture. We will give practical step-by-step recommendations for performing all operations.

Procurement of materials and tools

Calculate how much Rotband gypsum plaster is needed: 5 kg for local work or a dozen bags for decorating a spacious room. Buy the right amount of mixture and the necessary tools:

- primer brush or roller;

- level;

- drill (mixer);

- metal rail;

- wide spatula;

- cotton gloves;

- sand paper;

- device for aligning angles;

- beacons.

Depending on the type of surface, different primers are required; anticorrosion agents are needed to protect metal parts.

Important! When buying, check the beacons for deformation. Organize the careful transportation of profiles, protect from damage in transit.

Surface preparation

Remove the old coating, degrease the concrete walls, treat the metal elements with a protective compound. Prime the walls and wait for the final drying.

Important! Grundirmittel and Rotband Soil are used for priming aerated concrete and brick. For polystyrene, cement and concrete surfaces, Concrete Contact is needed.

Install the beacons, adjust the height using a level, level it in a single plane, close the air gaps between the profiles and the base. The distance between the lighthouses is 140-170 cm.

Make a solution

Read the recommendations for the preparation of the mixture on the package: the instruction is printed on bags of standard volumes. Take a clean container (plastic bucket) and fill the third part with room temperature water. Pour the dry mixture gradually, stir with a drill or mixer. Bring the solution to the consistency of sour cream, wait 10 minutes, mix again. This mode will increase the ductility of the plaster.

Important! So that the solution does not dry out on the spatula, lumps do not form in the mixture, follow the mandatory rules: do not use hot water, do not add any components to the finished mixture, do not immediately make a lot of solution.

The humidity level in the room where the plastering works are carried out should not exceed 60%.

Apply the plaster to the surface.

First, with the help of a spatula, the space between the two beacons is filled a meter from the floor. Then the surface is leveled by the rule: the tool in 2-3 receptions is carried out in a zigzag on the plaster, the excess solution is dumped into a bucket.

Important! With large differences in relief, the building crest helps. While the solution has not dried up, it is carried out with the help of teeth and a rough surface is created. After final hardening, the protrusions enhance adhesion during the secondary application of the plaster.

Within an hour, the solution is compacted, and it is possible to begin surface alignment with a metal bar to fill the voids.

Useful Tips

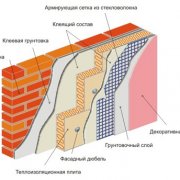

- The base of expanded polystyrene or cement is covered with a reinforcing network. It is glued with PVA or plaster to the surface, smoothed, eliminated bubbles and primed. The plaster is applied after the primer has dried.

- In rooms with a high level of humidity, apply an additional waterproofing layer to the base.

- Wash the tools immediately after finishing work, otherwise the remaining solution will dry tightly.

- During the weekly period of drying the plaster, provide good ventilation in the room, but without drafts.

- If you plan to stain or glue the wallpaper, wipe the wall with a stiff brush after pre-wetting the plaster with water.

The combination of operational advantages and affordable cost of the Rotband is the reason for the popularity of the material among finishing specialists.