What is better insulation for plaster

Insulation and decoration of the facade is a difficult and time-consuming exercise, and if we talk about hinged ventilated systems, then there will be no difficulties with the installation of insulation, but what if plaster is chosen as the finishing material? In this article we will talk about insulation for plaster, and about what materials will be needed for this.

The content of the article

Heaters

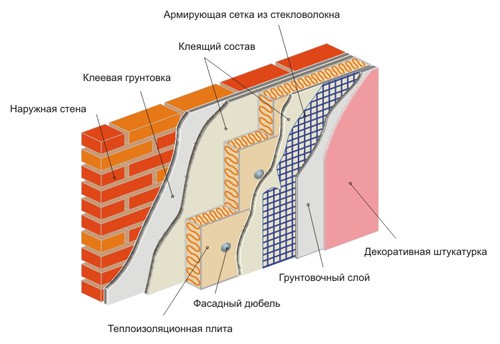

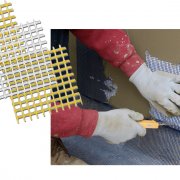

As you can see in the photo at the beginning of the article - plastering over the insulation is not limited to only these two materials. The whole system consists of many layers, and not depending on which pair, insulation plaster is selected, the presence of a layer of soil and a reinforcing mesh are simply necessary.

Only in this way can you create a high-quality and durable coating that will not only save heat in the house, but will also look aesthetically pleasing. First of all, you need to understand the question of how to insulate walls for plastering, and there are several options, each of which has its pros and cons, but first things first.

Mineral wool

Mineral wool is a material that has been popular for many years, as it has a huge list of quality characteristics, and due to its environmental friendliness and incombustibility, it can be used on any objects without restrictions. It is this insulation that is used in the construction of social facilities and child care facilities.

There is also basalt insulation for plaster, which is one of the varieties of mineral wool, but with elevated temperature ranges. Most often it is used to warm baths and other rooms in which frequent changes in temperature are present.

Pros:

- It does not burn and does not support combustion.

- It is completely safe for health.

- It can be mounted at any time of the year and at any temperature.

- Easy to cut, and installation can be done with your own hands and without special difficulties.

- It has high vapor permeability. That does not allow condensate to accumulate under the surface of the insulation.

- Relatively low price in comparison with other types of insulation of the same thickness.

- Resistant to all types of solvents and alkalis.

Minuses:

- Plaster on a mineral wool insulation should be applied in a thin layer and have a small weight.

- With constant exposure to moisture, it can deform and lose its quality characteristics.

- Due to the softness of the material, it can be easily damaged mechanically.

Interesting! Many people still confuse mineral wool with glass wool, which was used in the past and caused irritation of the skin when touched. Mineral wool is completely devoid of this drawback, and it can be touched with bare hands without special protective equipment.

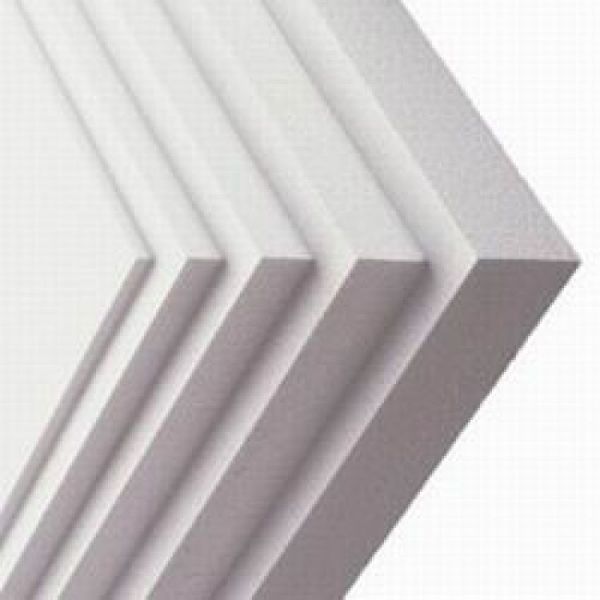

Styrofoam

Foam insulation for walls under the plaster (see Styrofoam plaster - how and why it is needed), no less popular than mineral wool, but in contrast to it has a number of restrictions on use. This is due to low resistance to high temperatures, and even though most types of modern foam have special flame retardants in their composition, when melted, it emits toxic fumes that can significantly harm health.

Pros:

- Polyfoam is a lightweight material which does not create additional load on the walls.

- Not afraid of moisture and does not decompose on contact with water.

- Has a wide temperature rangeat which installation can be done.

- Easy to cut with a regular knife.

Minuses:

- It is dissolved in contact with chemical solvents.

- Emits toxic fumes when melted.

- It has low vapor permeability.

- It can deform at high temperatures.

Important! When choosing a foam for insulation of the facade, you need to look for the PSB-S marking, which means that the material contains flame retardants, and is non-combustible.

Penoplex

Choosing what to insulate walls with plaster for, more and more builders and homeowners give preference to foam, despite the fact that the cost of this material is much higher than that of competitors. This is explained by the fact that, compared with other types of insulation, foam is the most resistant to all influences, and due to its high density, it is very difficult to damage.

In fact, this is also polystyrene, but its production uses active freons, which create very small bubbles inside the plate, while the freons themselves evaporate without residue, and small air chambers remain in their place.

Pros:

- Resistant to most types of solvents.

- Each plate has special grooves that greatly simplify the installation process.

- It has no temperature deformations and does not support combustion.

- It can be used both outdoors and indoors.

- Due to its high density, foam is very difficult to damage mechanically, and therefore it is often used for insulation of floors and roofs.

- Penoplex is completely insensitive to moisture, and even to a large amount of water.

Minuses:

- High price.

- If during installation the plate had to be cut, then the edges of the slice must be repaired, since through them the foam will begin to absorb moisture.

- Low vapor permeability.

- The instructions for working with foam boards allow mounting only on level surfaces. If polystyrene or mineral wool can take the form of surface irregularities, then polystyrene does not have this possibility.

Advice! Penoplex has various markings indicating its density, they can be from 21 to 45. In order to insulate the wall under the plaster, marking up to 35 is enough, since everything above this indicator is already a material of increased strength, which is most often used on objects with increased load.

Since we will not dwell on the question of how to plaster insulation, we will present a video in this article, which will clearly show the whole process.

Plaster

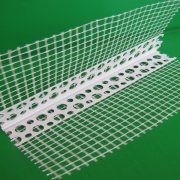

Plaster for wall insulation is applied over the insulation, with a fixed reinforcing mesh. There are no particular difficulties in the work, since the whole process differs little from applying a plaster mortar to a normal surface. The main thing is to clearly understand which mixtures can be used and whether they enter into a conflict reaction with the selected type of insulation.

For work, you can use several types of plasters, so dwell on each a little more.

Mineral plaster

Mineral plaster is a well-known cement mortar (see Let's consider how to plaster cement-sand mortar) The positive qualities of this material are well known, so it makes no sense to describe them in detail.

The main thing to remember when working with cement mixes is that they contain a large amount of alkali. It is neutral to all types of insulation, but can destroy the mesh of plastic, so for work it is necessary to choose reinforcement from composite or fiberglass.

Another disadvantage of mineral plaster is deformation and cracking during drying and natural shrinkage, so it is best to use a heater with a higher density, such as foam or polystyrene, but with a marking above 35.

Acrylic plaster

Unlike mineral plaster, acrylic does not contain alkali, which means that it can be used on any type of insulation and with any reinforcing mesh.

The only difficulty in working with this material is its quick solidification and low resistance to ultraviolet rays. You need to work with acrylic plaster at an accelerated pace, and in one approach you need to close the entire wall, because after a break in application, two sections of the wall may vary slightly in color.

Silicone plaster

Silicone plaster is one of the most expensive, but at the same time, high-quality materials that can be used on any surface. But if we talk about decorative plaster, then, as a rule, it contains stone crumb, which significantly increases the total weight of the coating.

Therefore, specialists try not to use it in tandem with mineral wool insulation, but if such a combination of materials is necessary, then the reinforcing mesh should be of high stiffness and density, and also have a very fine mesh.

Polymer plaster

Polymer plaster walls for insulation - this is one of the most durable and versatile methods of facade decoration. It perfectly interacts with all types of insulation and does not enter into conflicts, since there are no chemical solvents in its composition.

These and many other positive characteristics make polymer plaster one of the most popular materials, despite its relatively high cost.

As you can see, there are not so many plasters and insulation materials, and in order not to get confused in this variety, we give a small table that will help to clearly understand which materials can be used with each other and which are undesirable.

| Types of plaster | Types of insulation | ||

| Mineral wool. | Styrofoam. | Penoplex. | |

| cement | undesirable | undesirable | can |

| acrylic | can | can | can |

| silicone | undesirable | can | can |

| polymer | can | undesirable | can |

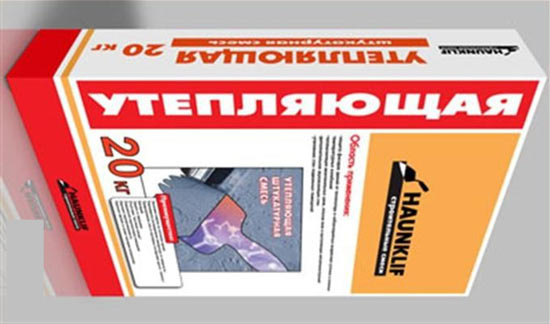

Plaster as a heater

We intend to separate this material into a separate category, since the insulating plaster is an independent material that does not require the creation of a multilayer coating.

For example, a huncliff warming plaster is applied directly to the wall, and at the same time it is a heater, of course, it cannot compete in heat capacity with mineral wool or polystyrene, and it is most often used as additional insulation when there is already a layer on the inside of the wall or heat-retaining material.

By the way, the huncliff can also be used as a stucco for insulation; the application technology in this case will not differ, but this method of facade insulation is rarely used, as it is overpriced. That is, for high-quality insulation of the house from the outside, it is much easier to purchase a thicker insulation than using independent plaster.